Water-cooled high-frequency transformer rectifier

A technology of high-frequency transformers and rectifiers, applied in the field of rectifiers, can solve problems such as small operating space, inconvenient operation, and falling of protective covers, and achieve the effect of solving inconvenient wiring and facilitating wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

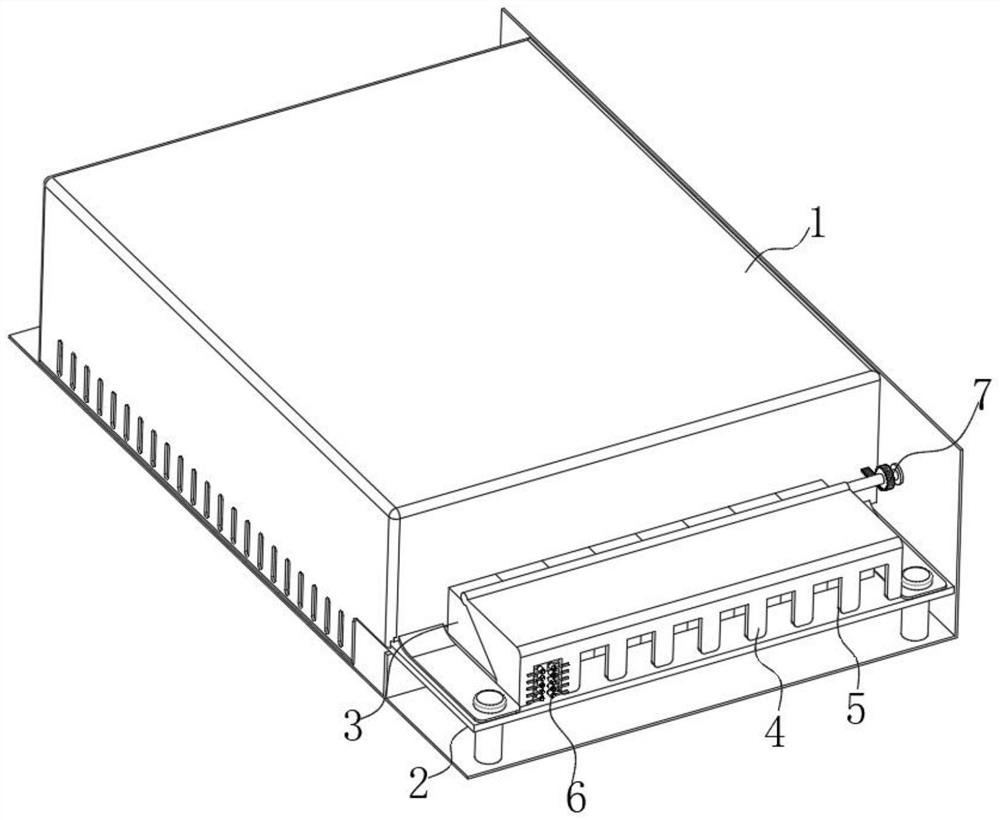

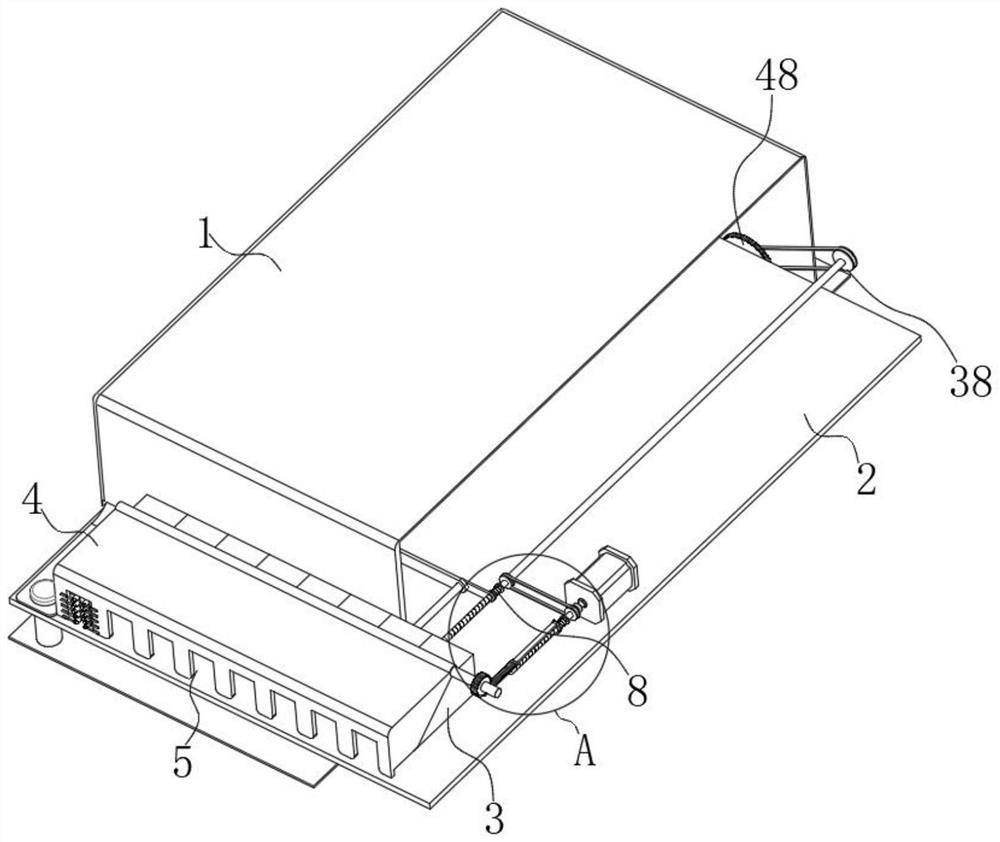

[0028] see figure 1 with figure 2 Describe embodiment 1, a water-cooled high-frequency transformer rectifier in the figure, including a rectifier body 1, a rotating assembly 7 and a pushing assembly 8, the rectifier body 1 is fixedly connected with a circuit board 2, and the circuit board 2 has multiple electrical connections Assemble terminal 3, and terminal 3 is slidingly connected with circuit board 2, and the outer side of terminal 3 is provided with protective cover 4, and protective cover 4 is provided with multiple groups of gaps 5, and the positions of multiple groups of gaps 5 and multiple groups of terminal 3 Correspondingly, and multiple groups of gaps 5 are connected with fixing parts 6, the rotating assembly 7 for rotating the protective cover 4 is installed in the rectifier body 1, and connected with the protective cover 4, and the pushing assembly 8 for pushing the terminal post 3 Installed in the rectifier body 1 and connected with the terminal 3;

[0029] s...

Embodiment 2

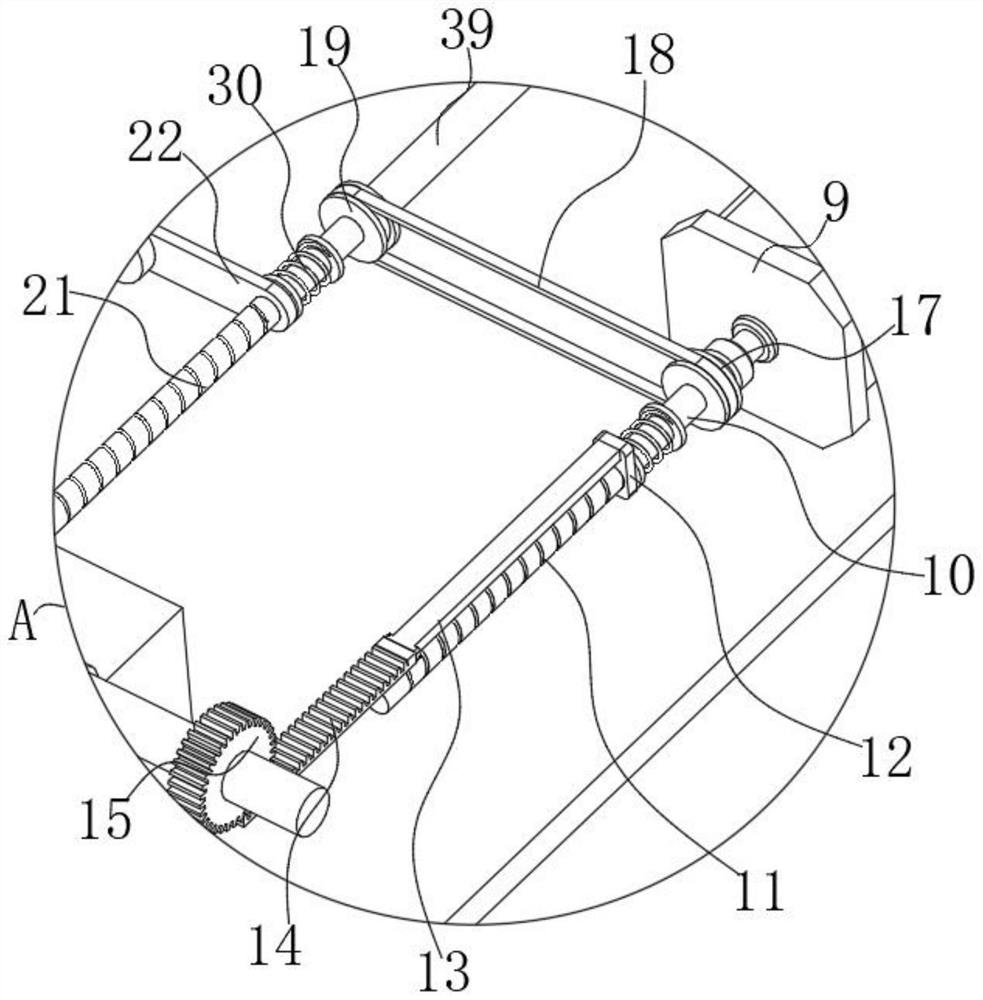

[0036] see figure 2 , Figure 8 with Figure 9 Example 2 will be described. This embodiment will further explain Example 1. In the figure, the other end of the first driven wheel 19 is connected to a heat dissipation assembly 48 for dissipating heat from the circuit board 2. The heat dissipation assembly 48 includes two sets of limiting parts. 30 and the reciprocating screw rod 31 located at the bottom of the circuit board 2, the two sets of limiters 30 are located on the drive shaft 10 and the connecting shaft 20 respectively, and one end is respectively set in contact with the first threaded rod 11 and the second threaded rod 21, the reciprocating wire The rod 31 is screwed with a moving frame 32 which is slidingly connected with the rectifier body 1. The moving frame 32 is rotatably connected with a first bevel gear 33 which is slidingly connected with the reciprocating screw rod 31. The first bevel gear 33 is fixedly connected with a reciprocating wire The limit block 4...

Embodiment 3

[0040] see image 3 with Image 6 Example 3 will be described. This embodiment will further explain Example 2. In the illustration, the limiting member 30 includes two groups of movable pieces 43, and the two groups of movable pieces 43 are respectively located at one end of the drive shaft 10 and the connecting shaft 20, and are respectively connected to The first threaded rod 11 and the second threaded rod 21 are arranged in contact, one end of the movable piece 43 is fixedly connected with the second spring 44, and one end of the second spring 44 is fixedly connected with the fixed piece 45, and the two groups of second springs 44 are respectively sleeved on the On the outside of the connecting shaft 20 and the driving shaft 10, two sets of fixing pieces 45 are respectively fixedly connected to the connecting shaft 20 and the driving shaft 10;

[0041] In this embodiment, when the threaded block 12 and the connecting piece 22 move onto the drive shaft 10 and the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com