Design method for intersecting-axis conical twin-screw rotor profile, rotor and equipment

A conical twin-screw and rotor profile technology, which is applied in mechanical equipment, rotary piston pumps, rotary piston machines, etc., can solve the problems of impractical rotors, stagnation, large taper, etc., and improve leakage and stress problems , Improve the force situation, improve the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] A method for designing a profile of a conical twin-screw rotor with intersecting shafts proposed by the present invention comprises the following steps:

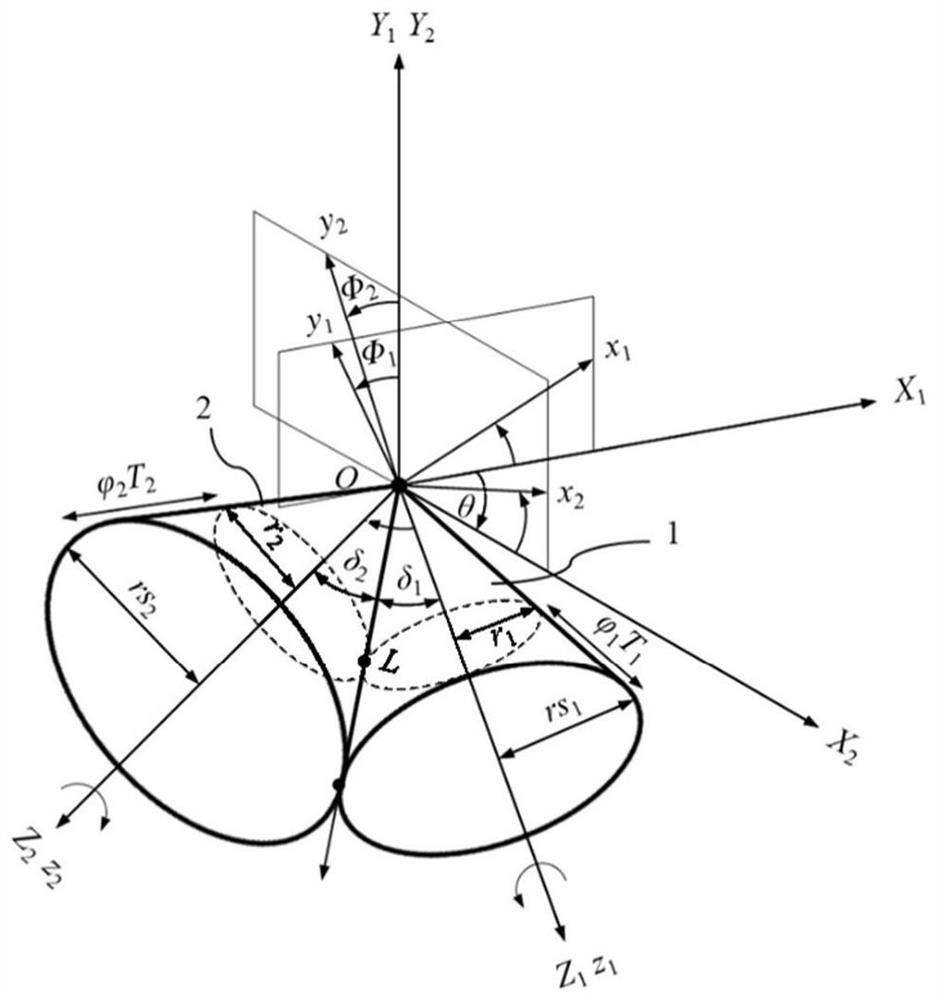

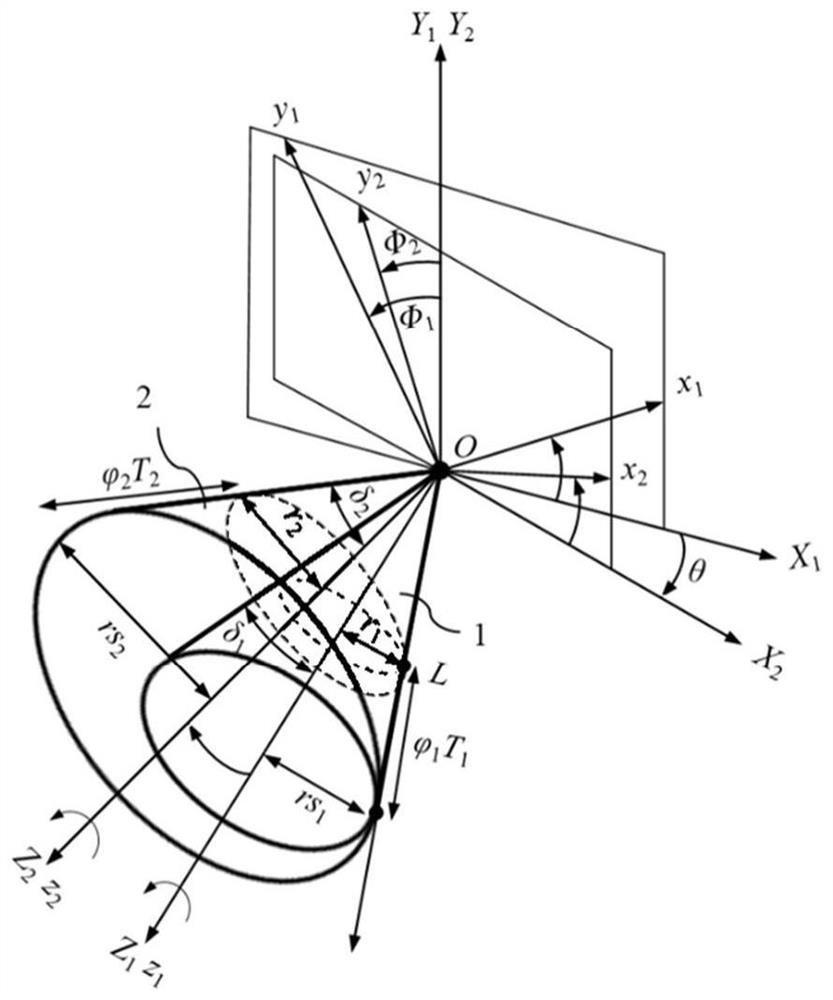

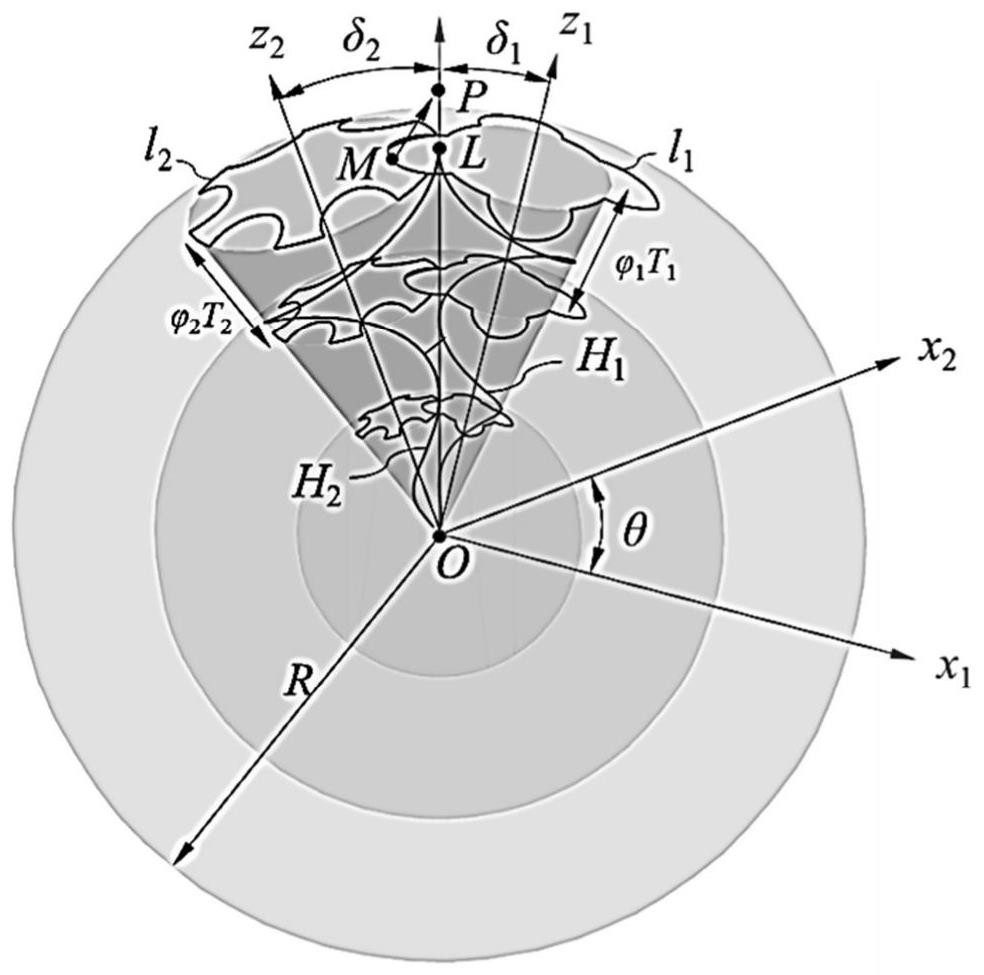

[0083] Such as figure 1 and figure 2 As shown, the first step is to establish the space external meshing model of the conical rotor. OZ in the picture 1 is the axis of rotation of rotor 1, OZ 2 is the axis of rotation of rotor 2, OZ 1 with OZ 2 Intersect at point O and make an angle θ. The meshing relationship of the rotor can be represented by two conical surfaces. The two cones make a pure rolling motion tangentially and their line of contact is always OL, which is called the clockwise axis of revolution. Such as image 3 and Figure 4 as well as Figure 5 and Figure 6 As shown, in the second step, on a series of spherical surfaces with the center of the sphere O and different radii, the profile line family required for the rotor 1 to form a cone is given. The third step is to obtain the conjugate curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com