Natural gas hydrate exploitation system and method combined with CO2 gas burying

A natural gas and hydrate technology, which is applied in the fields of mining fluids, other gas emission reduction technologies, earthwork drilling and production, etc., can solve the problems of reducing the risk of natural gas hydrate mining, causing geological disasters, and decreasing formation strength, so as to compensate for the loss of formation pressure , reduce stratum collapse, and achieve the effect of burying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] This embodiment takes natural gas hydrate reservoirs in a certain sea area of China as an example to illustrate a combined CO 2 The natural gas hydrate mining method for gas storage, specifically includes the following steps:

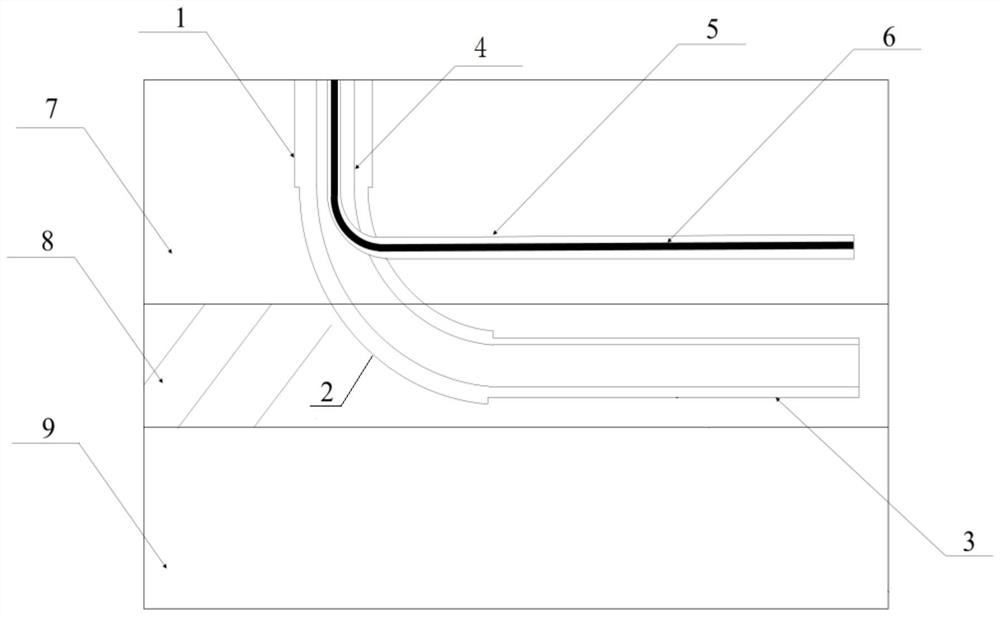

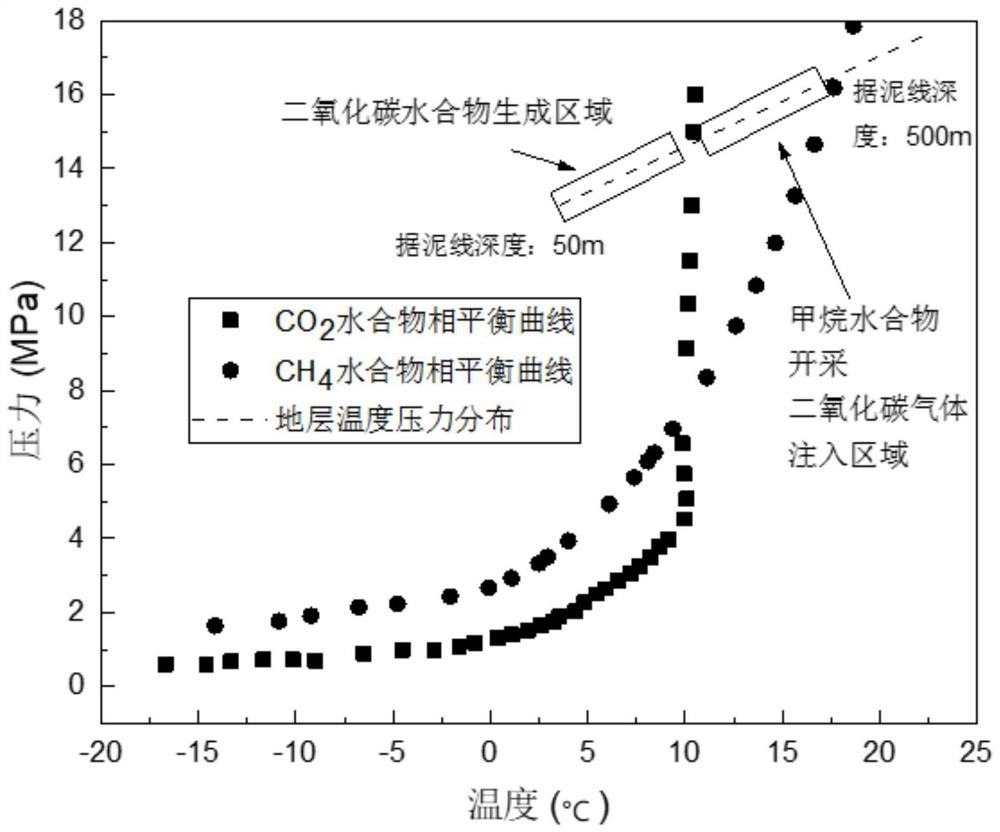

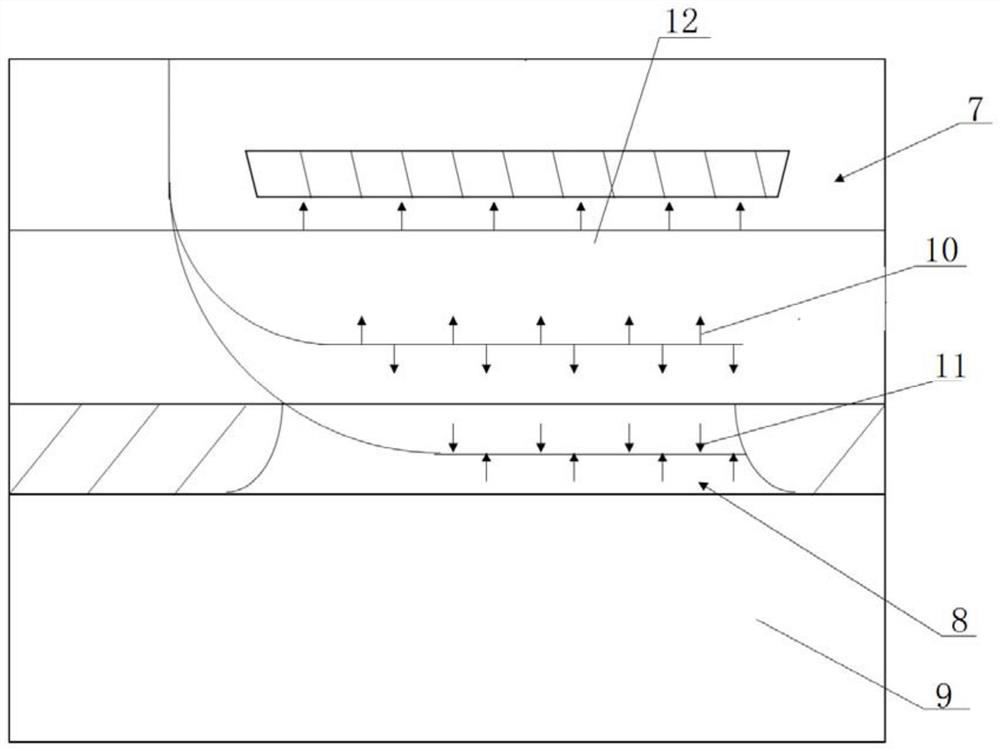

[0045] Step 1, according to the characteristics of gas hydrate reservoirs in this sea area determined by previous detection, such as figure 2 As shown, the figure includes the gas hydrate phase equilibrium curve, carbon dioxide hydrate phase equilibrium curve, formation temperature distribution characteristics and formation pressure distribution characteristics. The analysis shows that the gas hydrate formation and stable existence area is within 500m from the mud line. According to the According to the logging curve data in the sea area, the area with a distance of more than 315m from the mud line is classified as the underlying formation, the area with a distance of 205-315m from the mud line is classified as a natural gas hydrate reservoir,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com