Deep sea pressure compensation type oil-filled motor based on leather bag structure

A pressure compensation, oil motor technology, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as seawater infiltration, short circuit, etc., to achieve the effect of improving reliability, good elasticity, and avoiding excessive internal temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

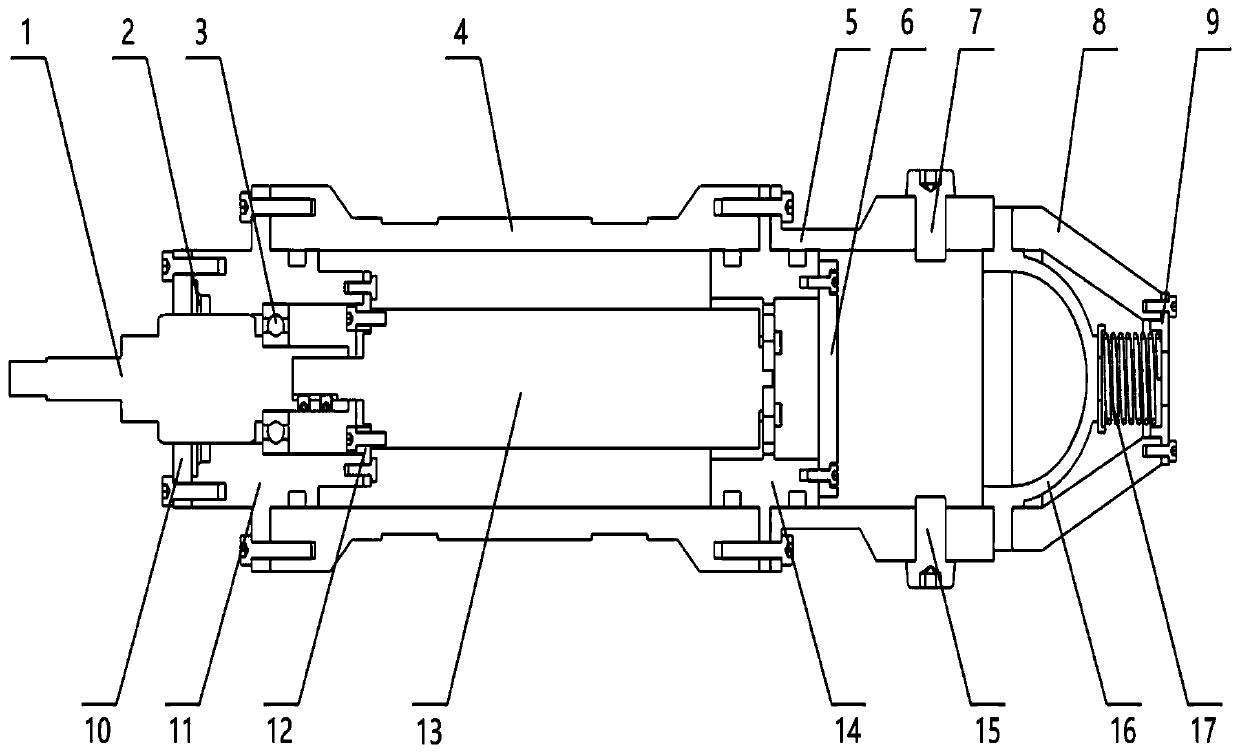

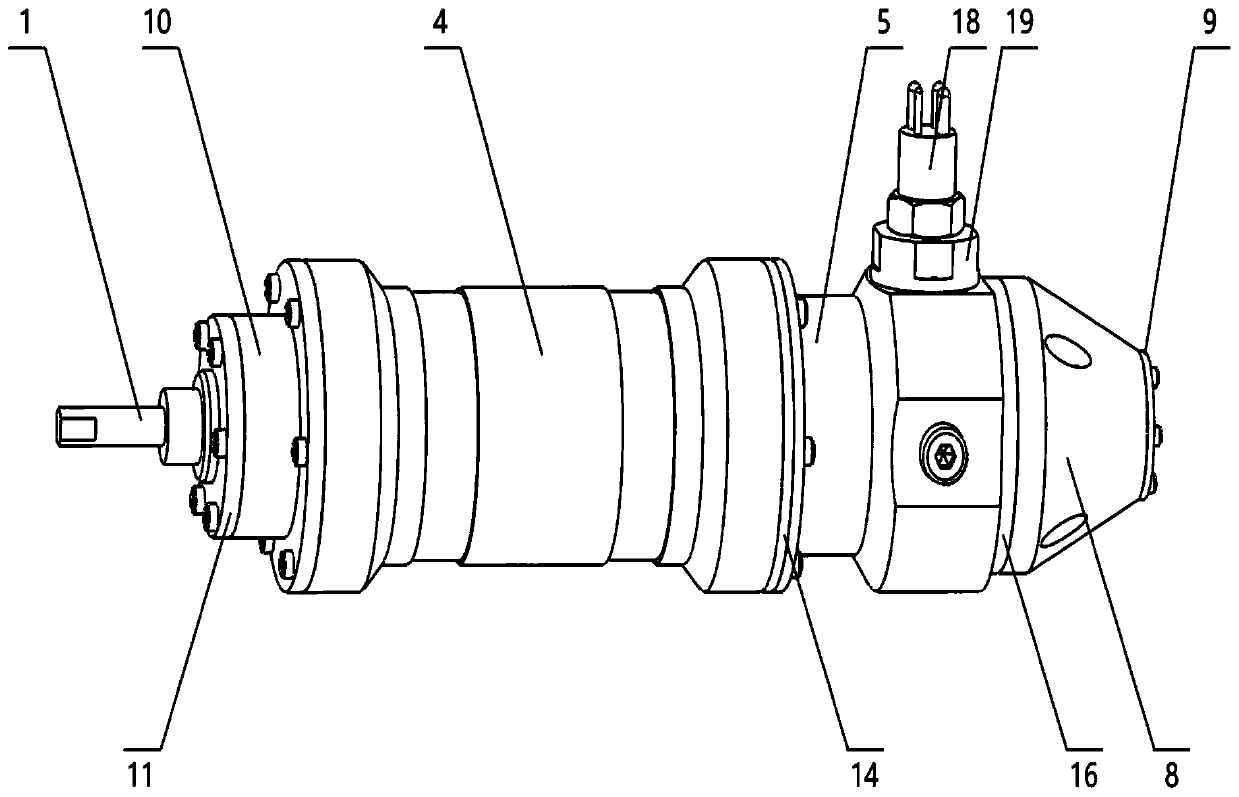

[0024] Such as figure 1 with figure 2 As shown, a deep-sea pressure-compensated oil-filled motor based on a bladder structure includes a front cabin 4 and a rear cabin 5. It also includes output shaft 1, pan stop ring 2, rolling bearing 3, drive plate 6, oil filling port plug 7, rear end cover 8, rear gland 9, front gland 10, front end cover 11, motor fixing plate 12, motor 13. Flange connection block 14, exhaust port plug 15, rubber bladder 16, compression spring 17, watertight connector 18 and threaded connection seat 19.

[0025] The front cabin 4 is a long cylinder, with threaded holes on the front and rear sides, and two grooves on the outer side, which are convenient for fixing with a hoop. The front end cover 11 is a cylindrical shape with a flange surface on the outside, is fixed to the front side of the front cabin 4 by bolts, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com