Plate delivery method, system and equipment based on robot sorting and medium

A technology of robots and boards, which is applied in the direction of instruments, manipulators, program-controlled manipulators, etc., can solve the problems of increased time for boards out of the warehouse, long time, and reduced efficiency of boards out of the warehouse, so as to improve the efficiency and improve the out-of-warehouse efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

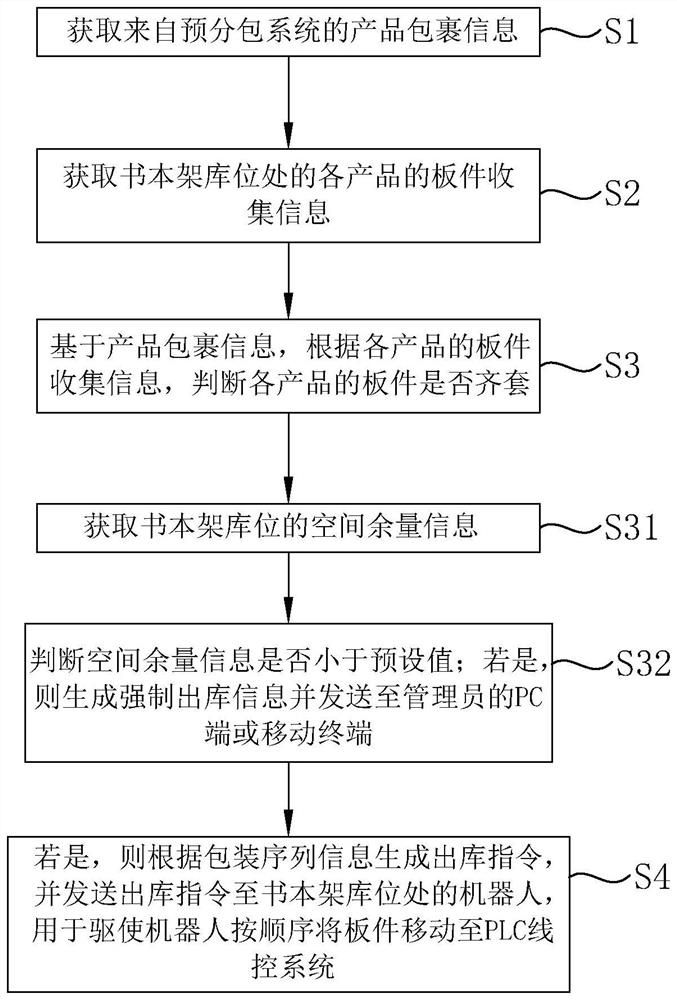

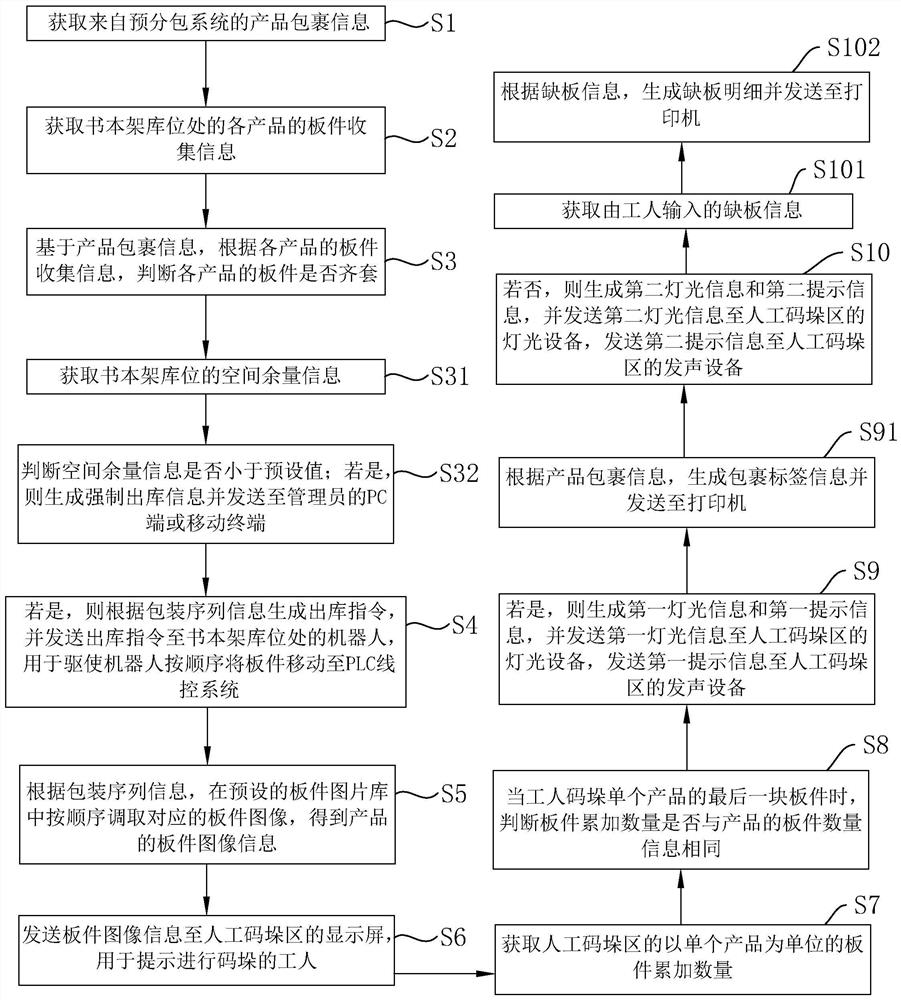

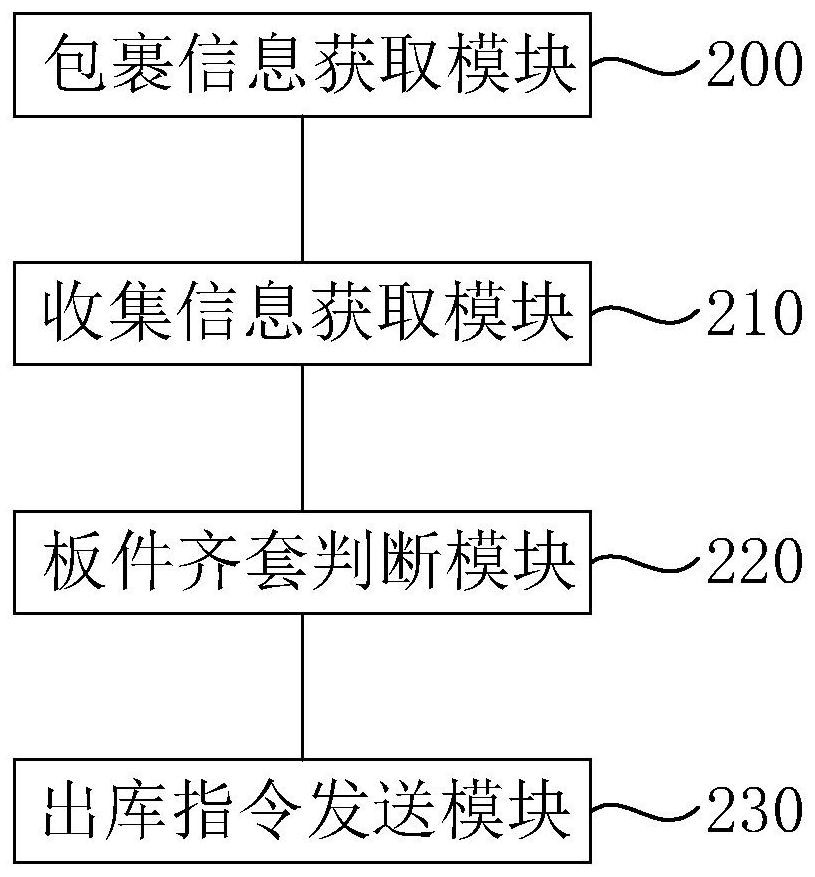

[0055] The following is attached Figure 1-4 The application is described in further detail.

[0056] refer to figure 1 , the present application discloses a method for outbound boards based on robot sorting.

[0057] A method for outbound boards based on robot sorting, comprising:

[0058] S1. Obtain product package information from the pre-package system.

[0059] The pre-subcontracting system refers to the system that subcontracts and pre-processes the existing boards in units of products. The pre-packaging system packs and combines the boards according to the products to realize the pre-packaging process, and generates product package information including all boards, and the product package information includes board attribute information, board quantity information and packaging sequence information .

[0060] The pre-packaging system is connected to the server, and is used to send the product package information to the server, so that the server can obtain the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com