Mounting mechanism for mounting sealing ring

An installation mechanism and sealing ring technology, applied in the mechanical field, can solve the problems of complex structure and low installation accuracy, and achieve the effect of simplifying the overall structure, reducing production costs and ensuring installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

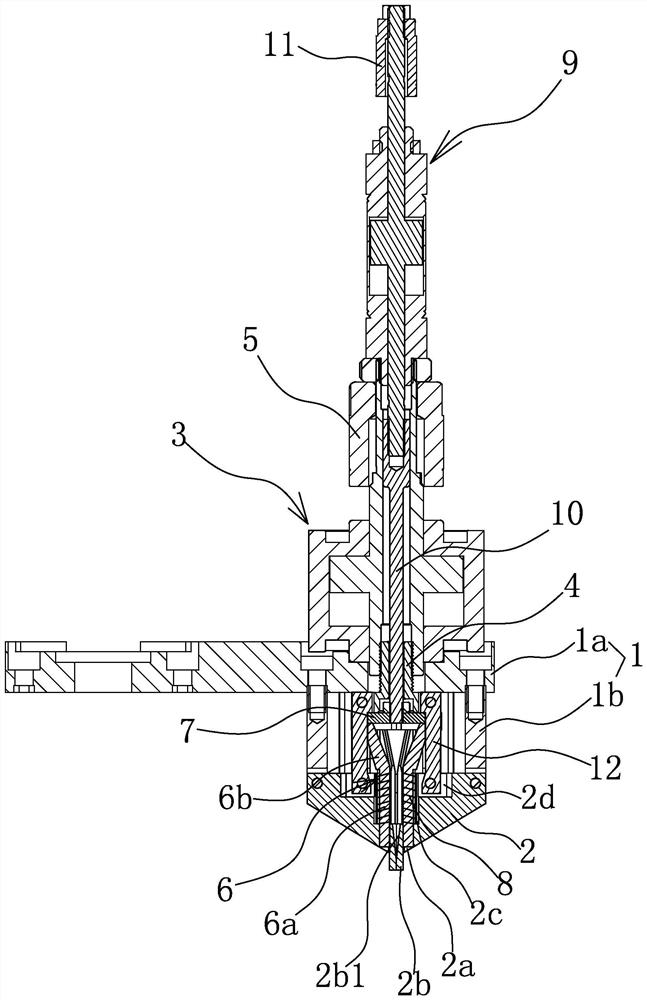

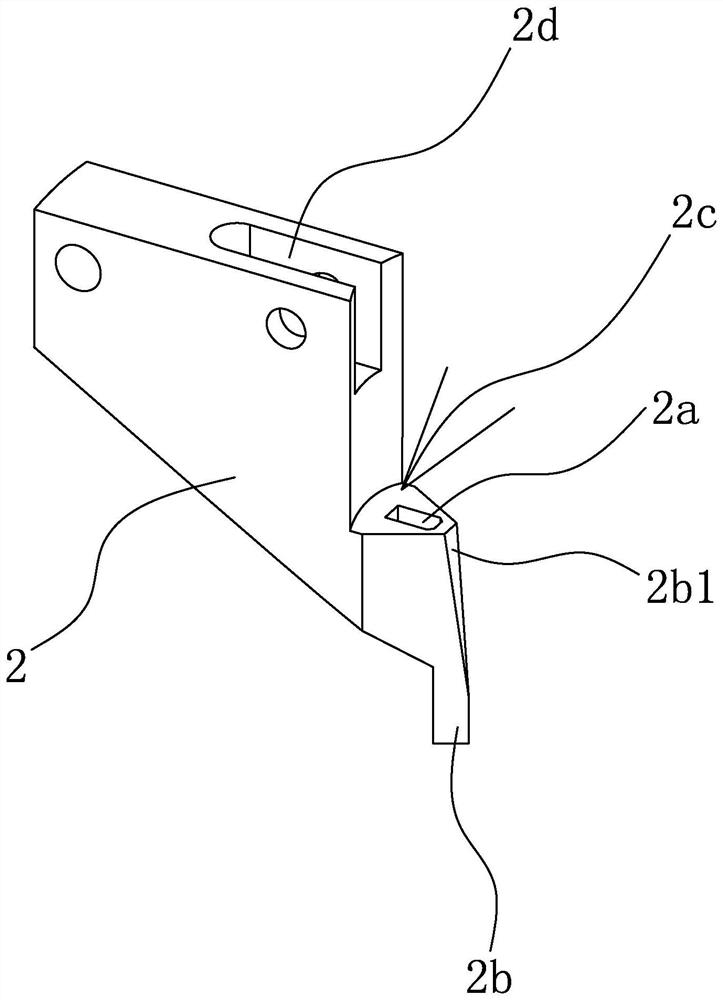

[0033] Such as figure 1 with figure 2 As shown, a mounting mechanism for installing a sealing ring includes a mounting base 1 and a number of support ring claws 2 connected to the lower side of the mounting base 1. Each support ring claw 2 is distributed along the circumferential direction and the lower end of each support ring claw 2 They can be gathered inwards or stretched outwards at the same time. Wherein, a support ring cylinder 3 is fixed on the upper side of the mounting seat 1, and the lower end of the piston rod of the support ring cylinder 3 is fixed with a coupling head 4 extending into the lower side of the mounting seat 1. Between the coupling head 4 and each support ring claw 2, there are Linkage structure, the upper end of the piston rod of the support ring cylinder 3 is threadedly connected with a spacer 5 that can abut against the upper end of the cylinder body of the support ring cylinder 3 when the piston rod of the support ring cylinder 3 moves downward....

Embodiment 2

[0038] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the linkage structure includes a tapered block located at the lower end of the coupling head 4 and whose outer diameter gradually decreases from top to bottom, and a support ring claw 2 fixedly connected transmission rods, the upper end of the transmission rod abuts against the outer peripheral wall of the conical block and the support ring claw 2 is slidably connected with the mounting seat 1 along the radial direction of the conical block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com