Artificial graphite welding preparation device

A technology of artificial graphite and welding surface, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high production cost, low product performance, time-consuming and labor-intensive, etc., to improve welding quality and welding material thickness uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

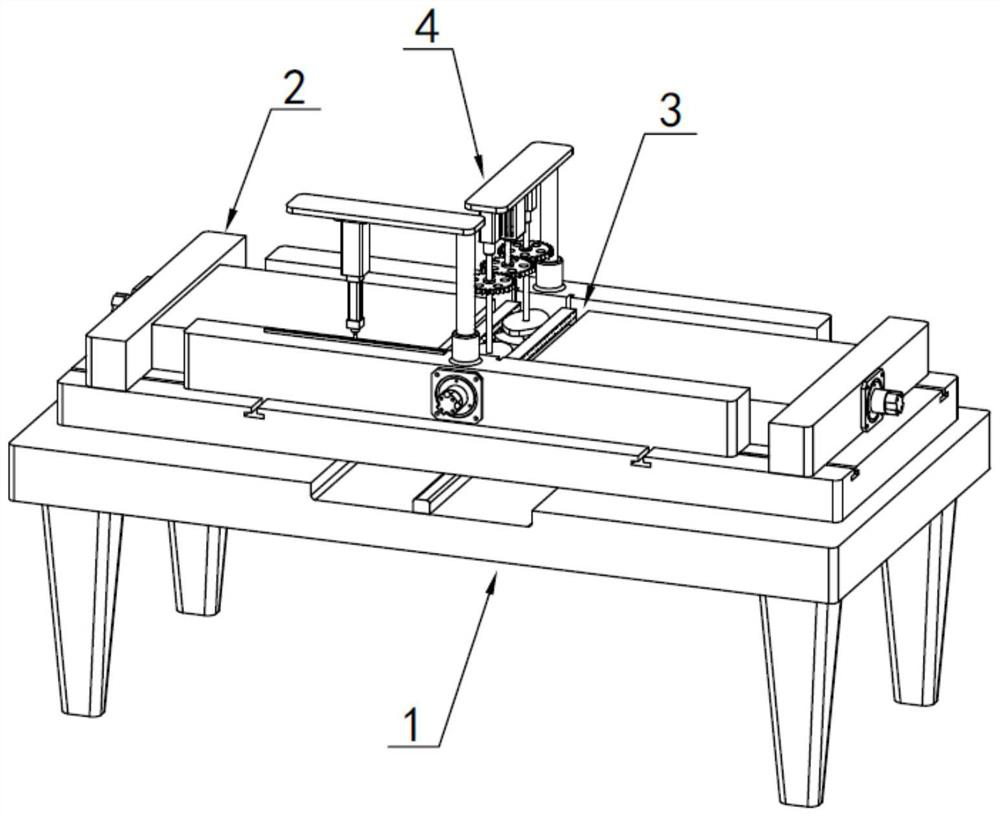

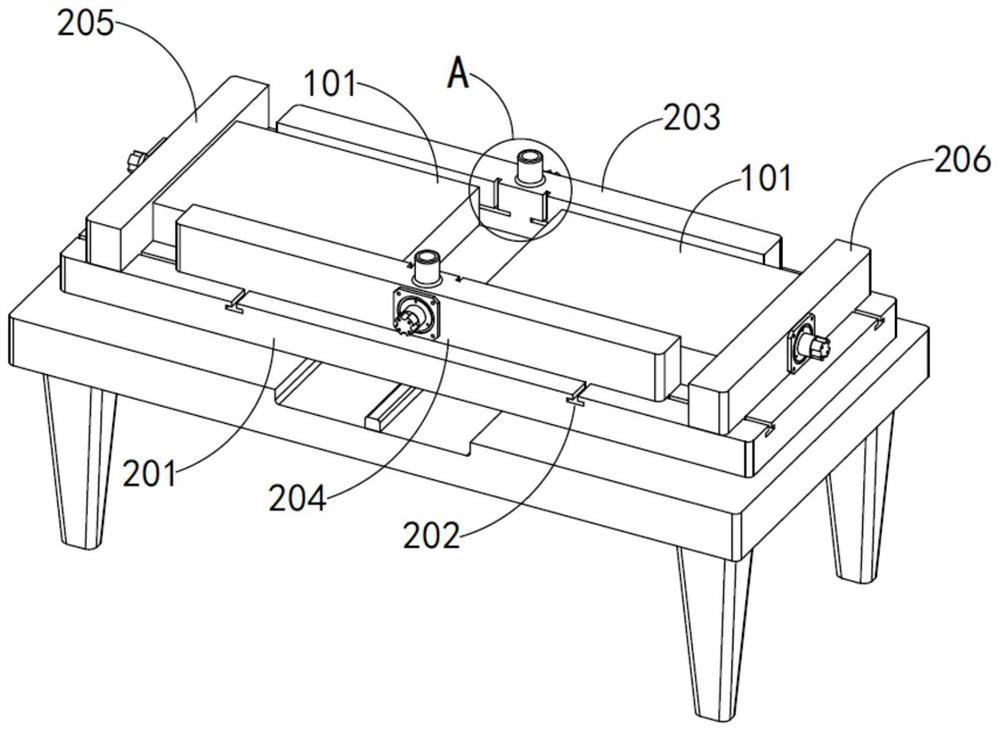

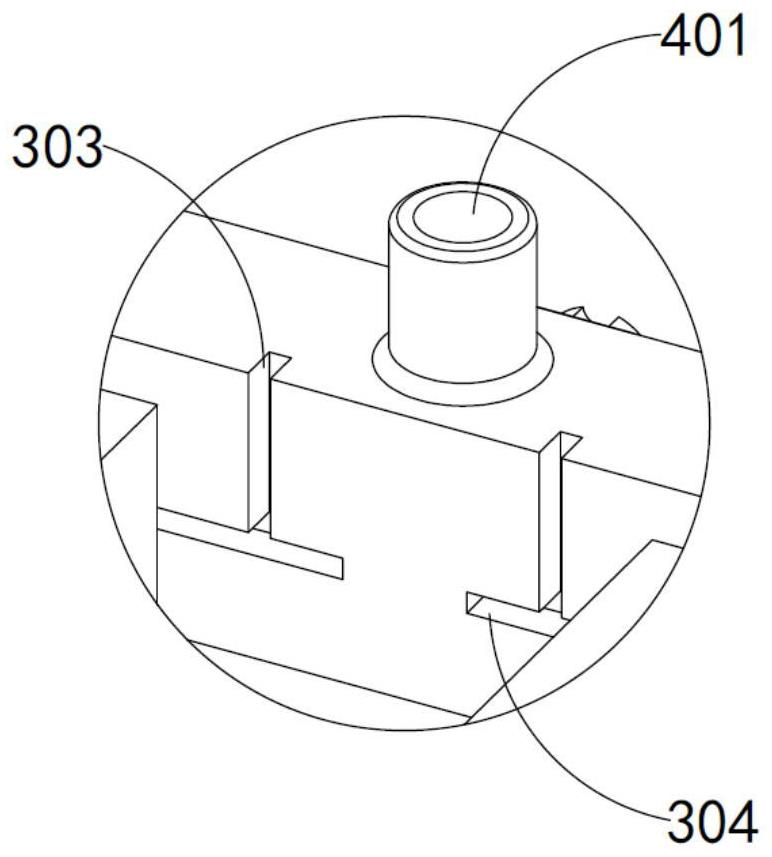

[0029] Such as Figure 1 to Figure 8 As shown, the embodiment of the present invention provides an artificial graphite welding preparatory device, including a bearing platform 1, a limiting component 2 is arranged on the supporting platform 1, and the limiting component 2 is used to fix the side cut surface of the limiting artificial graphite 101, and the artificial graphite 101 is provided with a top pressure assembly 3, the top pressure assembly 3 includes a top pressure block a301 and a top pressure block b302, the top pressure block a301 is used to compress the welding material on the outer ring of the artificial graphite 101 welding surface, and the top pressure block b302 is on the The top pressure block a301 is used to compress the welding material on the inner ring of the artificial graphite 101 welding surface after top pressure, and the drive assembly 4 is also arranged between the top pressure components 3, and the drive assembly 4 drives the top pressure block a301 ...

Embodiment 2

[0041] as attached Image 6 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The difference is that a flattening assembly 5 is also arranged on the limit block b204, and the flattening assembly 5 includes a rotating driving seat 501, on which a pressing seat 502 is rotated, and a cylinder 503 is fixedly arranged on the pressing seat 502 With the flattening strip 504 pushed by the cylinder 503, the flattening assembly 5 can compact and flatten the welding material between the graphite welding contact surfaces by pushing the flattening strip 504 through the cylinder 503 after the artificial graphite 101 is closely bonded.

[0042] It is particularly noted that the welding material of the present invention is stirred and mixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com