Annular electromagnetic induction pump

An electromagnetic induction and electromagnetic pump technology, applied in the field of electromagnetic pumps, can solve the problems of assembling the electromagnetic pump system, such as difficult, difficult to adjust, and non-adjustable, to achieve the effects of increasing usability, ensuring heat transfer, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Describe the prior art ring electromagnetic induction pump's figure 1 It has been described above and will not be reconsidered here.

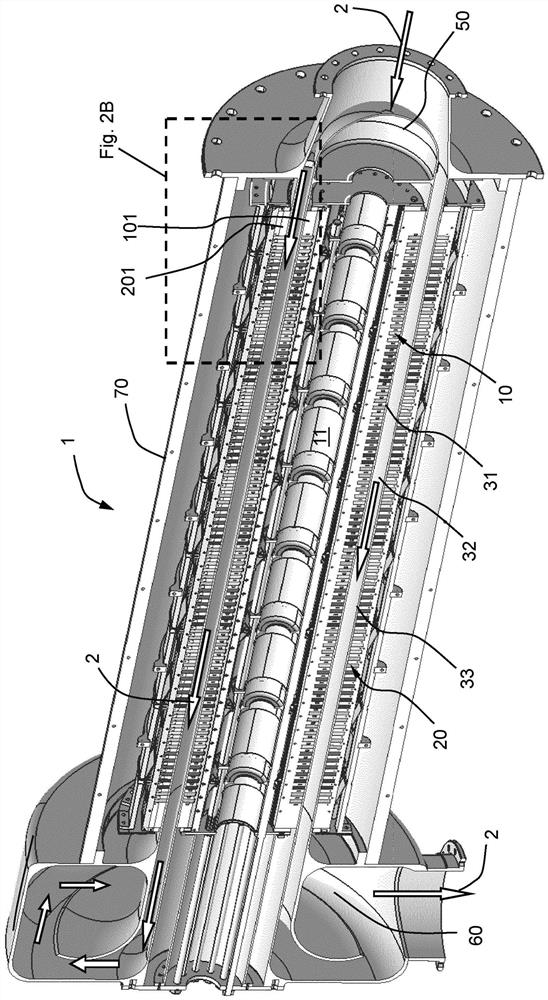

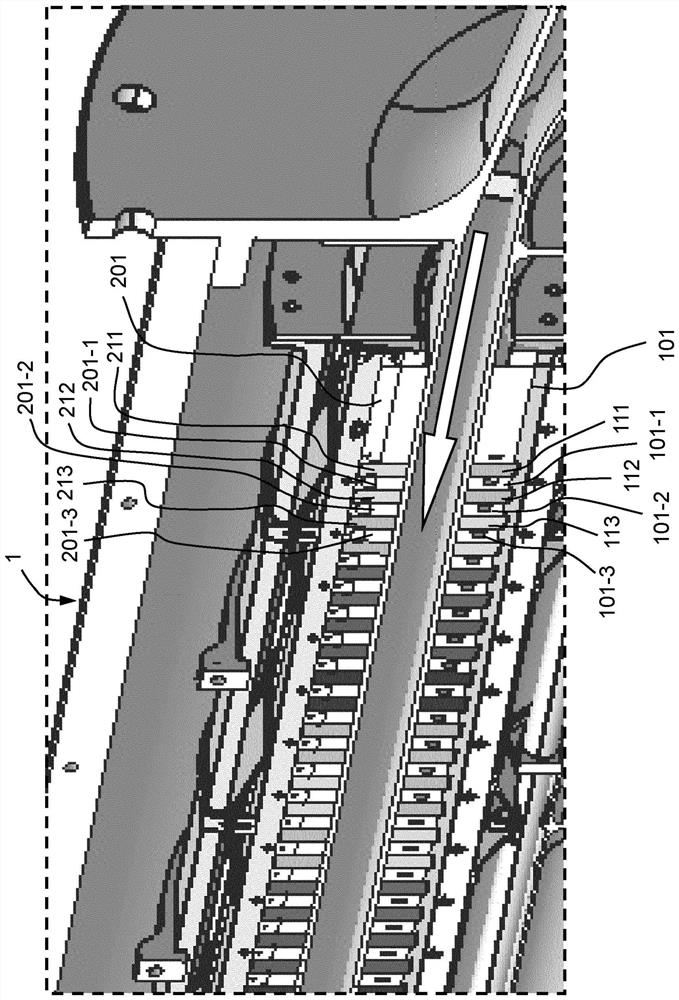

[0066] Figure 2A , 2B , 3A and 3B depict an embodiment of an electromagnetic pump according to the invention, and Figure 3A and 3B Specifically depicting the pump's internal sensor. Figure 4 The moving device of the electromagnetic pump according to the embodiment is described in detail. Figure 5A and 5B The mobile device is depicted in two different radial positions.

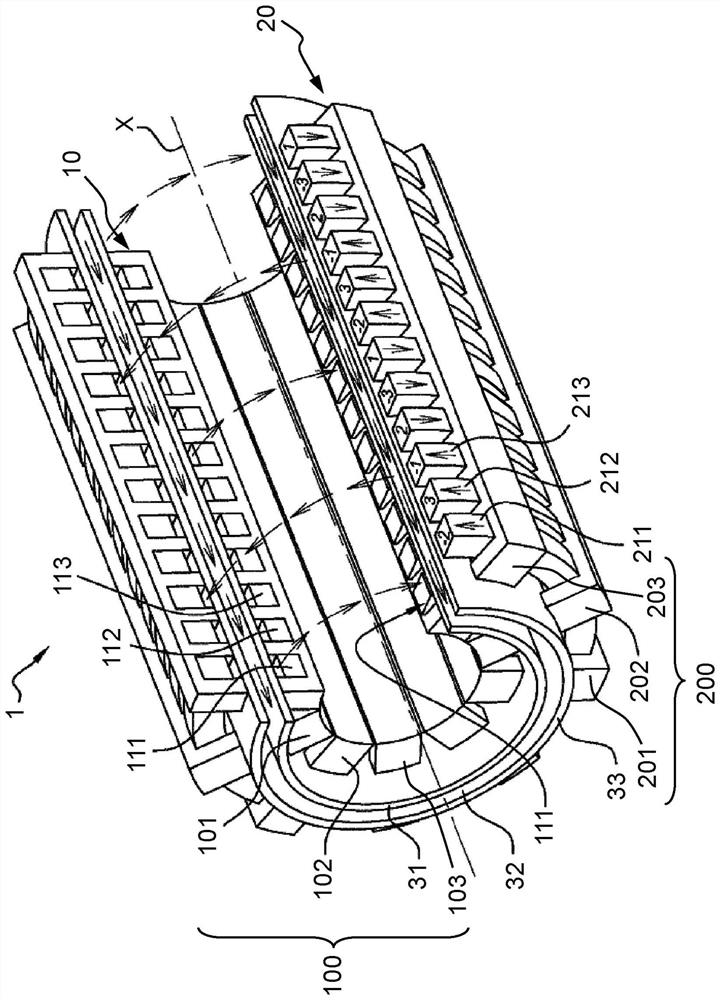

[0067] The electromagnetic pump is a ring electromagnetic induction pump, which is figure 1 In the same way the electromagnetic pump of the shown prior art starts from the central axis X of the electromagnetic pump 1 (which is also the longitudinal direction) comprising:

[0068] - internal inductor (or internal stator) 10;

[0069] - the inner tube 31, which contains the inner inductor;

[0070] - a pumping channel 32 in which the fluid 2 to be pumped can c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com