Returning light monitoring device of pulse fiber laser

A fiber laser and monitoring device technology, applied in the laser field, can solve problems such as real-time monitoring during the application process, and achieve the effects of online real-time monitoring of return light power, low cost, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is attached figure 1 to attach Figure 6 The present invention is described in further detail.

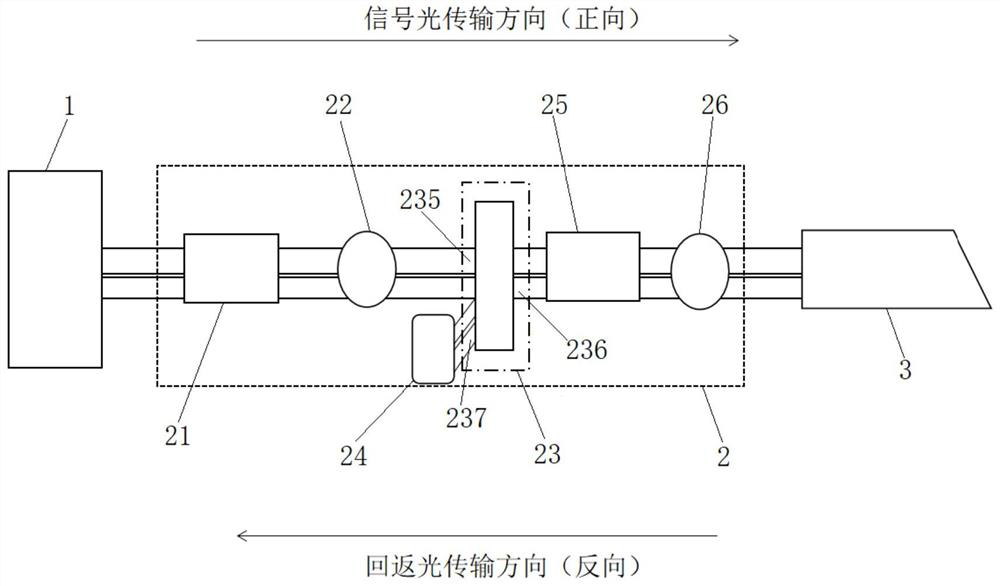

[0028] The embodiment of the invention discloses a pulsed fiber laser return light monitoring device. The present invention can separate return light and signal light, accurately calibrate signal light, and monitor the power of return light in real time online. Its main functional structure is as attached figure 1 shown in the dotted box. attached figure 1 The uppermost arrow in the figure is the signal light transmission direction (forward direction), and the lowermost arrow is the return light transmission direction (reverse direction).

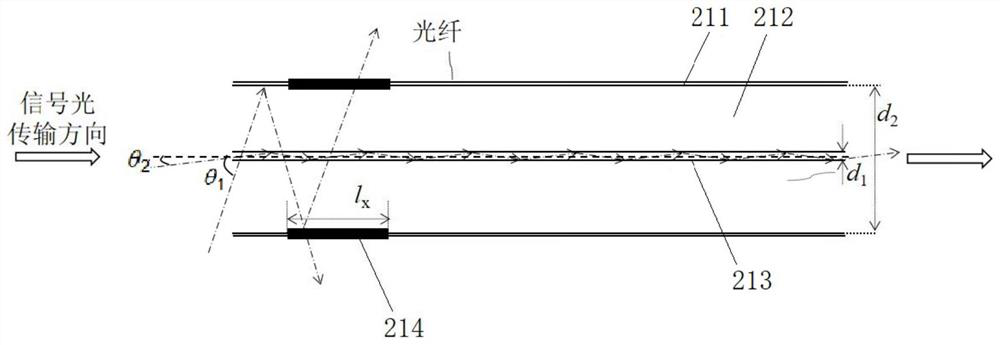

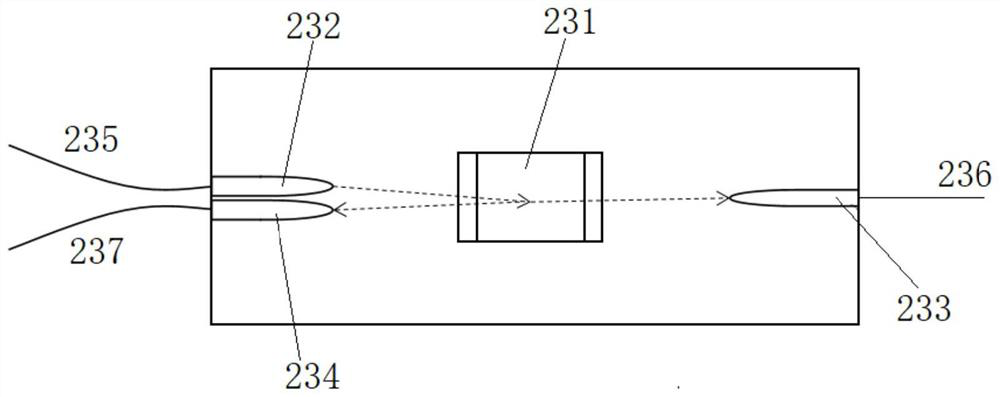

[0029] The return light monitoring device 2 is located between the laser gain fiber 1 and the laser output head 3, including a forward cladding optical processor 21, a forward core optical detector 22, a reverse core optical processor 23, a reverse core Light collector 24 , reverse cladding light processor 25 , and ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| isolation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com