Indoor evaluation method for carbon dioxide pollution of drilling fluid

A carbon dioxide, indoor evaluation technology, applied in the preparation of test samples, measuring devices, instruments, etc., can solve the problems of not considering whether the carbon dioxide gas is all absorbed, not actually equivalent, and the effect of the pH value of the drilling fluid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Preparation of carbon dioxide indicator solution: add 0.1 g of bromothymol blue to 100 ml of 20% ethanol solution to prepare a carbon dioxide indicator; take 200 ml of tap water, add 2-3 g of carbon dioxide indicator to it, and then form a carbon dioxide indicator solution.

[0050] Preparation of soil slurry: Add 20 g of sodium bentonite to 400 mL of distilled water, stir at 11,000 rpm for 20 minutes at a high speed, and then hydrate in a closed state for 24 hours to form a soil slurry.

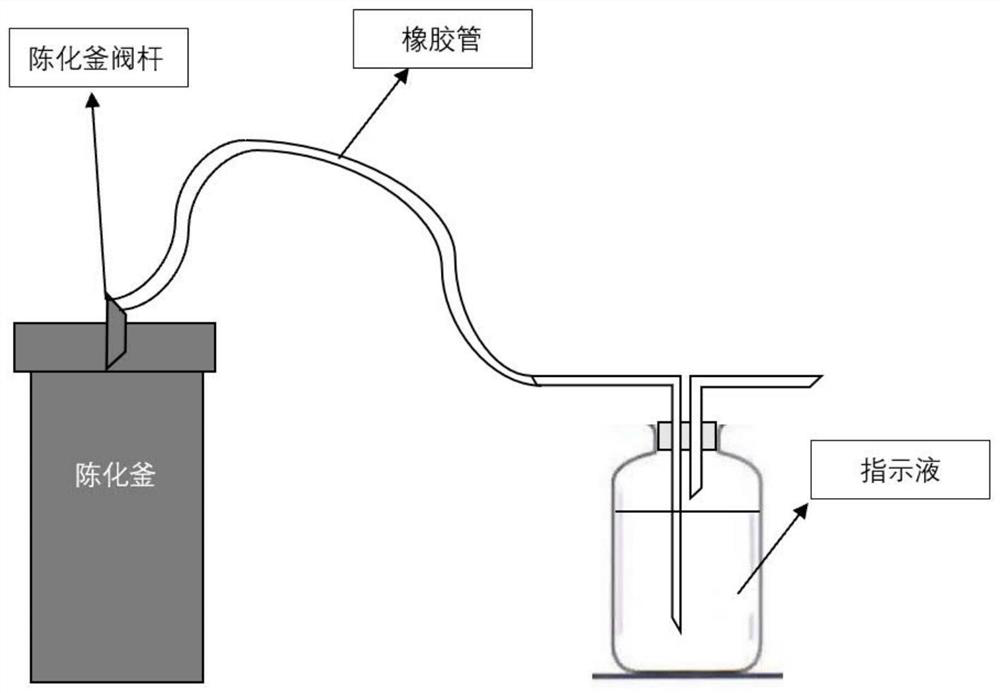

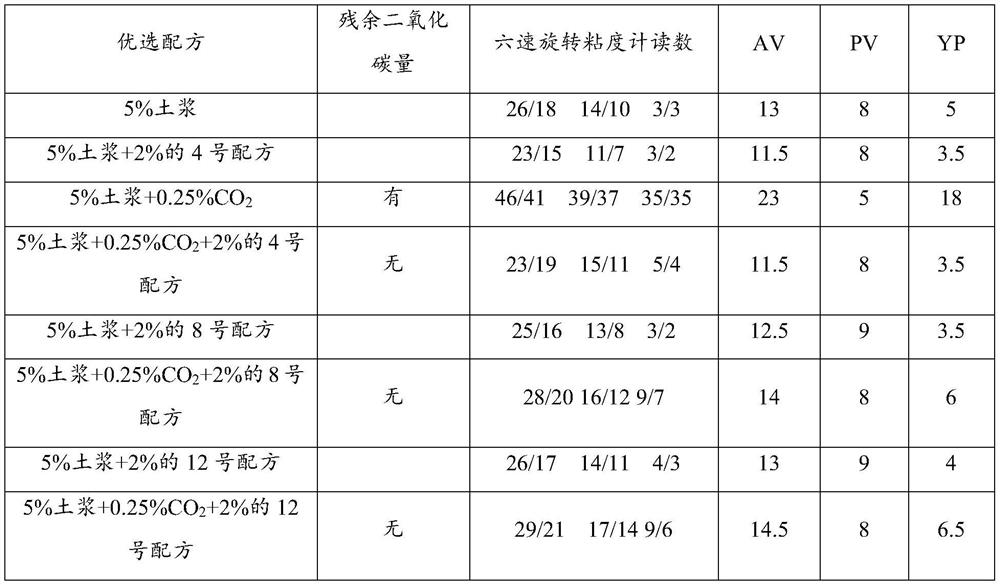

[0051] Prepare 4 parts of the above-mentioned soil slurry, which are respectively recorded as 1#, 2#, 3#, 4#; 8.0 g of the treatment agent sample for preventing the drilling fluid from being polluted by carbon dioxide is added to the 2# and 4# slurry, and the above-mentioned 1#, 2#, 3#, and 4# four slurries were stirred at high speed for 5 minutes under the high-speed mixer; prepare 4 aging kettles cleaned with distilled water, check whether the valve stem of the aging kettle is connec...

Embodiment 2

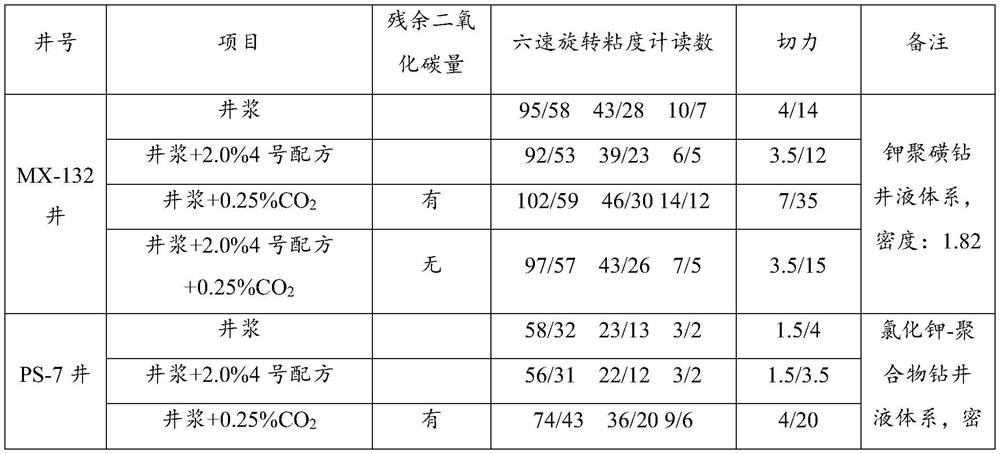

[0063] Similar to the steps in Example 1, the difference is that the soil slurry is replaced with well slurry.

[0064] Judgment on whether there is residual carbon dioxide in the aging kettle:

[0065] When opening the valve stem of the 4# slurry aging tank to communicate with the carbon dioxide indicator solution, if the gas in the tank makes the indicator solution change from blue to green or yellow, it indicates that the gas contains carbon dioxide; if it is connected, no gas overflows, or If the overflow gas does not change the color of the indicating solution, it means that no carbon dioxide gas is detected in the residual gas.

[0066] Performance test of well slurry in aging kettle:

[0067] Using No. 4 formula as the formula of treatment agent to prevent drilling fluid from being polluted by carbon dioxide, two different well muds, well mud + 2% formula, well mud + 0.25% CO were tested 2 And well mud + 0.25% CO 2 Viscosity values, AV, PV and YP of a six-speed rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com