Thorn tube and method for eliminating bubbles in thistle tube of thistle tube type ferrograph

A tube and catheter technology, applied in the tube and its elimination of air bubbles in the tube of a tube-type ferrgraph, can solve the problems of abrasive particle arrangement damage, oil samples and cleaning agent bubbles, etc., to reduce the generation of bubbles, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

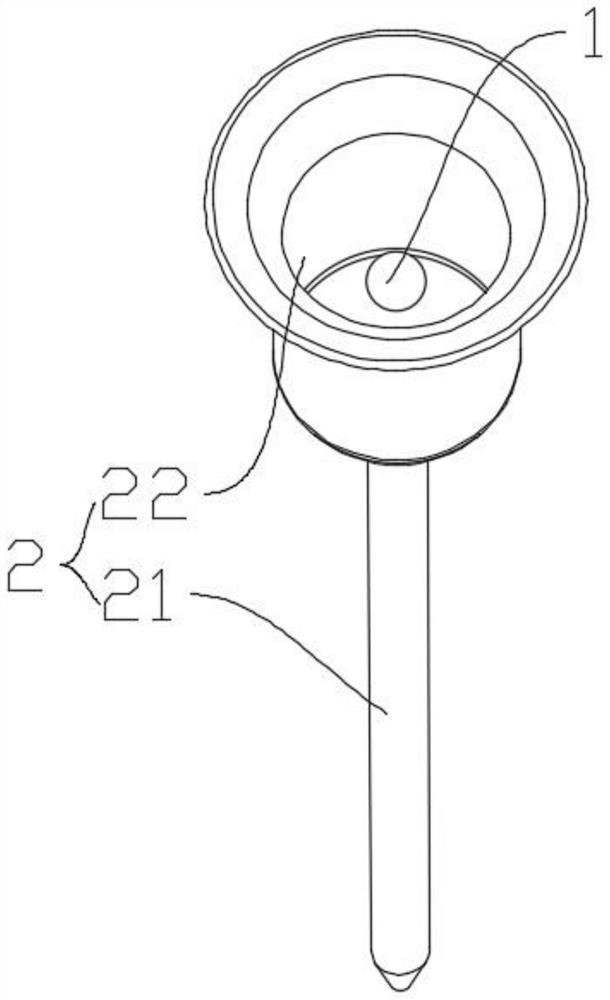

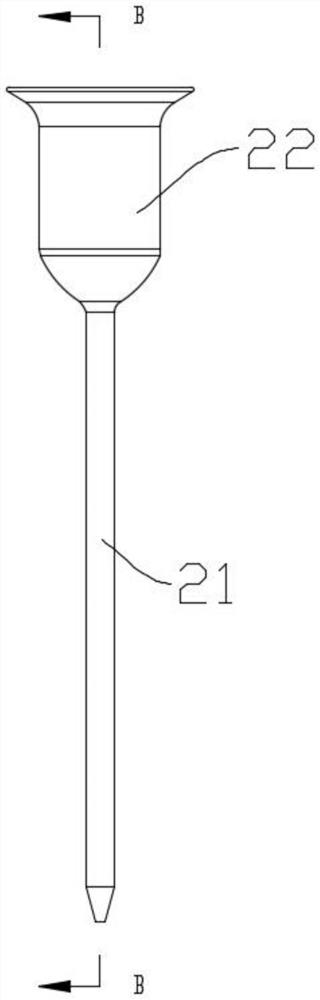

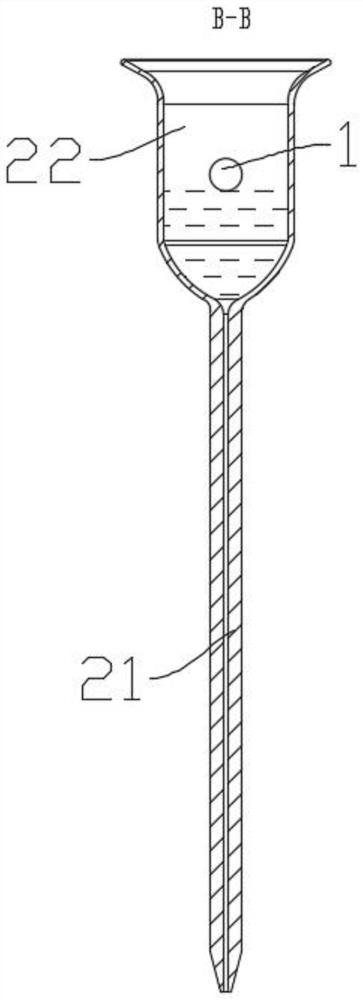

[0034] Such as Figure 1-4 As shown, the thistle tube of embodiment 1 and the method for eliminating air bubbles in the thistle tube of thistle tube ferrgraph include thistle-shaped glass tube 2, which includes a funnel 22 and a conduit 21 which are arranged in communication, and the funnel 22 is movable A suspension is provided, the density of the suspension is not greater than the density of the oil sample and the cleaning agent, and the suspension is sealed with the inlet of the conduit 21 .

[0035] The suspension part is a hollow ball 1 , and the diameter of the hollow ball 1 is larger than the inner diameter of the conduit 21 .

[0036] The hollow ball 1 is a polypropylene hollow ball.

[0037] A method for eliminating air bubbles in the thistle tube of thistle tube type ferrography instrument, comprising:

[0038] Step 1. When the oil sample flows through the funnel 22, the hollow ball 1 changes with the liquid level of the oil sample in the funnel 22;

[0039] Step ...

Embodiment 2

[0045] Such as Figure 5 As shown, Embodiment 2 is based on Embodiment 1, the difference is that: the outer wall of the hollow ball 1 is provided with several grooves 11 .

[0046] The difference between embodiment 2 and embodiment 1 is: the groove 11 can produce certain resistance to the flow of oil or cleaning agent, when the hollow ball 1 rolls, the oil or cleaning agent cannot be taken out by the hollow ball 1, thus The generation of oil or cleaning agent air bubbles is reduced.

Embodiment 3

[0048] Such as Figure 6 As shown, Embodiment 3 is based on Embodiment 1, the difference lies in that the center of gravity of the hollow ball 1 and the center of the ball are misplaced.

[0049] There is a distance between the center of the circle where the inner wall of the hollow ball 1 is located and the center where the outer wall is located.

[0050]The difference between Embodiment 3 and Embodiment 1 is that the center of gravity of the hollow ball 1 is deviated from its center. When the hollow ball 1 is suspended in oil or cleaning agent, its center of gravity is always kept below the center. At this time, the oil Or when the cleaning agent falls, the hollow ball 1 shakes in a certain small range without rolling, thereby avoiding the generation of air bubbles in the oil or cleaning agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com