Process for separating upper floating body from lower floating body of offshore platform

A technology of offshore platforms and floating bodies, which is applied to special-purpose ships, warships, motor vehicles, etc. It can solve problems such as high risk, difficult to control wind field climate conditions, and high cost, so as to save costs, reduce separation risks, and have sufficient equipment resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

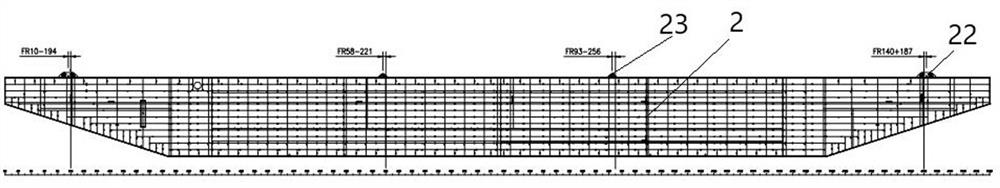

[0049] Such as Figure 1 to Figure 6The upper and lower floating body separation process of an offshore platform is shown, which is used to separate the upper and lower floating bodies 2 of the offshore platform. The offshore platform includes the upper floating body 1 and the lower floating body 2. Before the separation of the offshore platform, the upper floating body is 100m long, 48m wide, and 14m deep. , the structural weight is 16913.9T, the towing draft is 7.2m, the length of the lower floating body is 75m, the width is 48m, the molded depth is 6m, and the structural weight is 5022.1T. After the offshore platform is separated, the draft of the upper floating body 1 is 10.087m, and the molded depth of the lower floating body 2 6m, several locking devices 21 are installed on the lower floating body 2, and the locking devices 21 include a locking frame and locking pieces arranged in the locking frame.

[0050] The separation process of the upper and lower floating bodies o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com