Household timber batch production cut-off equipment

A technology for mass production and cutting equipment, used in wood processing appliances, forming/shaping machines, special forming/shaping machines, etc., which can solve the problems of wood cutting processing, poor functionality, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

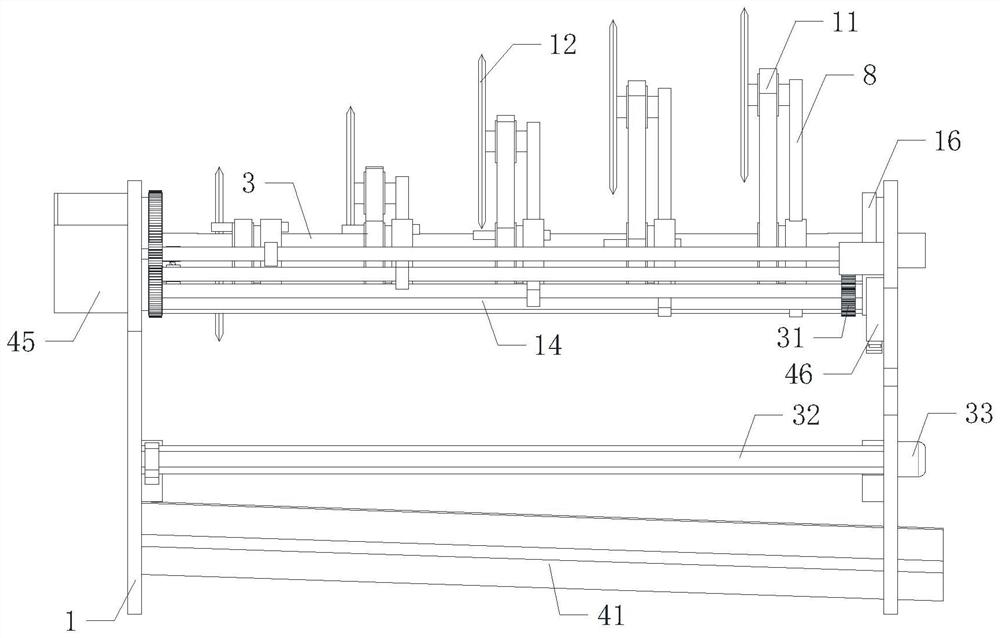

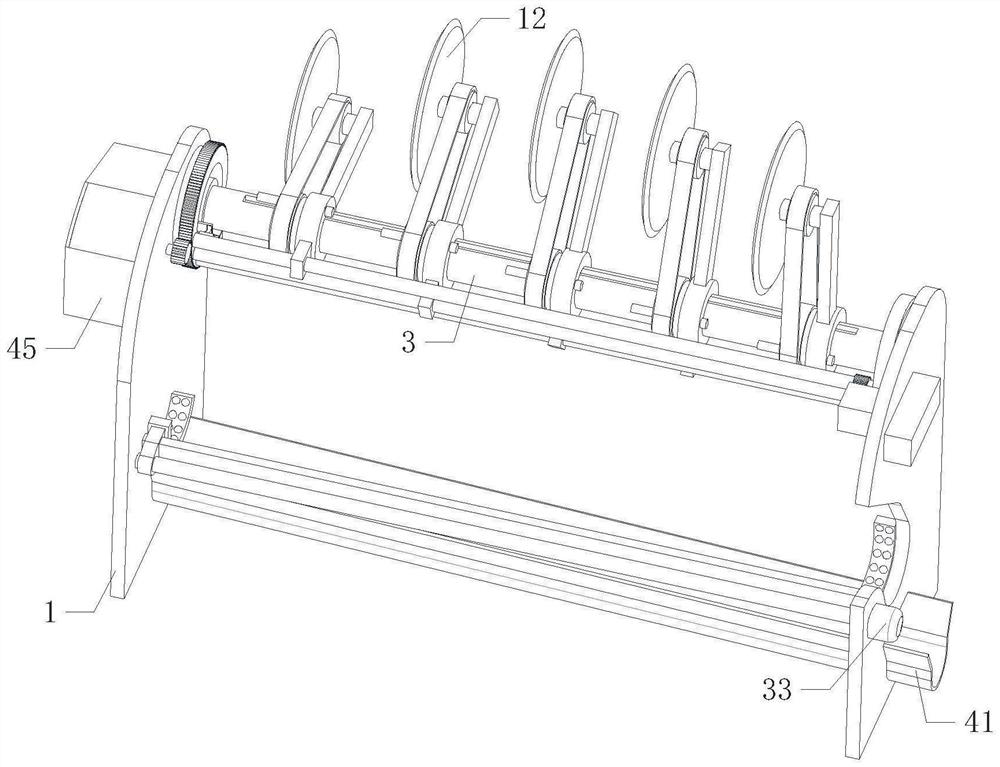

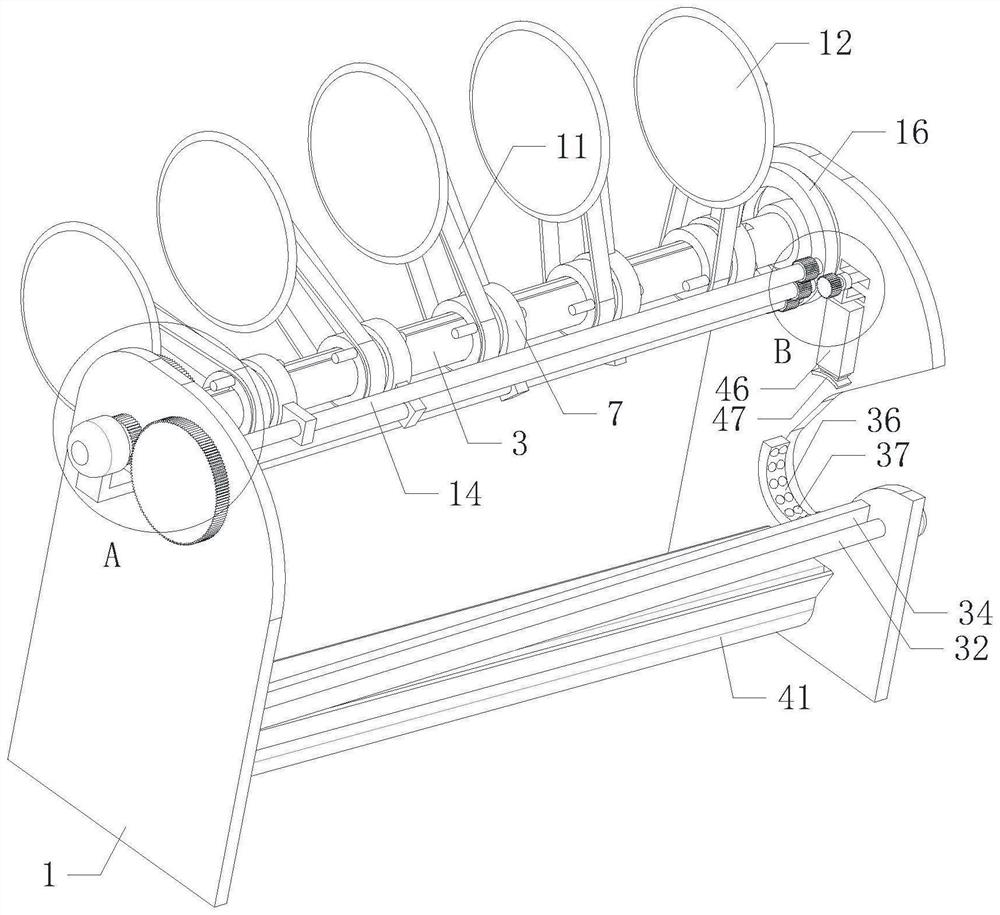

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0024] Such as Figure 1 to Figure 9 As shown, a kind of home furnishing timber mass production cutting equipment of the present invention, when it is working, open the first motor 17, the first motor 17 drives the second rotating shaft 19 to rotate, and the second rotating shaft 19 drives the main shaft 3 and the first straight gear 20 Rotate synchronously, the main shaft 3 in the rotating state drives the two sets of synchronous keys 5 of each group of cutting devices to rotate through the two groups of key grooves on it, thereby driving the belt transmission sleeve 4 in each group of cutting devices to rotate, the belt transmission sleeve 4 and the main shaft 3 Synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com