Carton glue paper sealing machine

A glue and carton technology, applied in packaging sealing/fastening, transportation packaging, packaging, etc., can solve problems such as sticking to the guide roller, unsmooth transmission of paper strips, retraction of paper strips, etc., to achieve convenient operation and processing High efficiency and uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

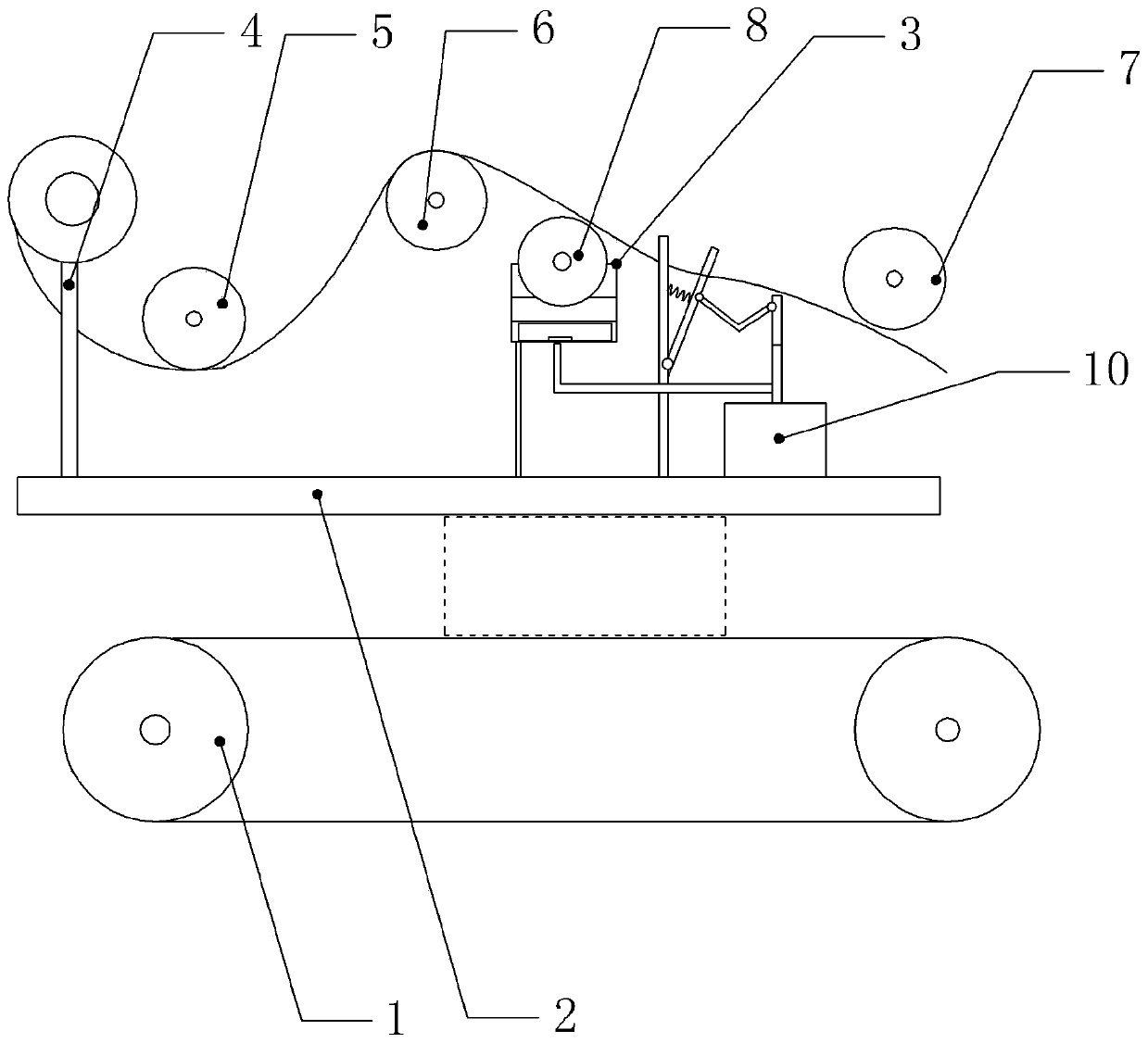

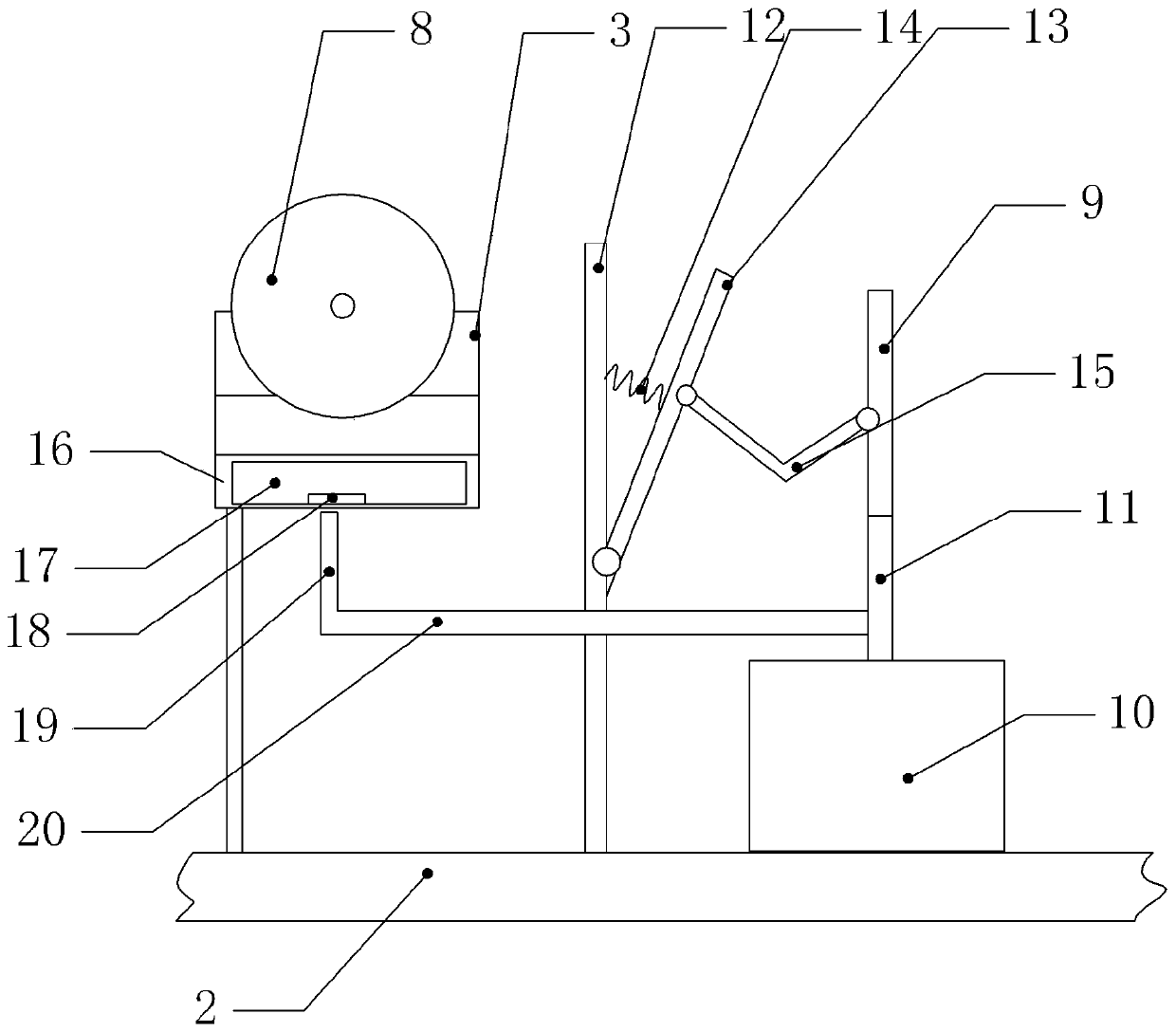

[0019] The reference signs in the drawings of the description include: transmission mechanism 1, pressure plate 2, glue tank 3, hanging rod 4, first guide roller 5, second guide roller 6, third guide roller 7, glue roller 8, cutter 9. The first cylinder 10, the first piston rod 11, the fixed plate 12, the movable plate 13, the first spring 14, the connecting rod 15, the heat preservation box 16, the cloth bag 17, the sheet metal 18, the vertical bar 19, and the horizontal bar 20.

[0020] Example figure 1 , figure 2 with image 3 Shown: Carton glue paper sealing machine, including transmission mechanism 1, transmission mechanism 1 is a conveyor belt mechanism, two parallel pressure plates 2 are arranged above the transmission mechanism 1, there is a certain distance between the pressure plate 2 and the upper surface of the conveyor belt mechanism, and the two pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com