Decontamination process for radioactive source tank

A source tank and process technology, applied in the field of radioactive source source tank decontamination technology, can solve the problems of intractable source tank processing and complex geometric structure, and achieve the effects of reducing pressure, avoiding lead smoke pollution, and reducing decontamination treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

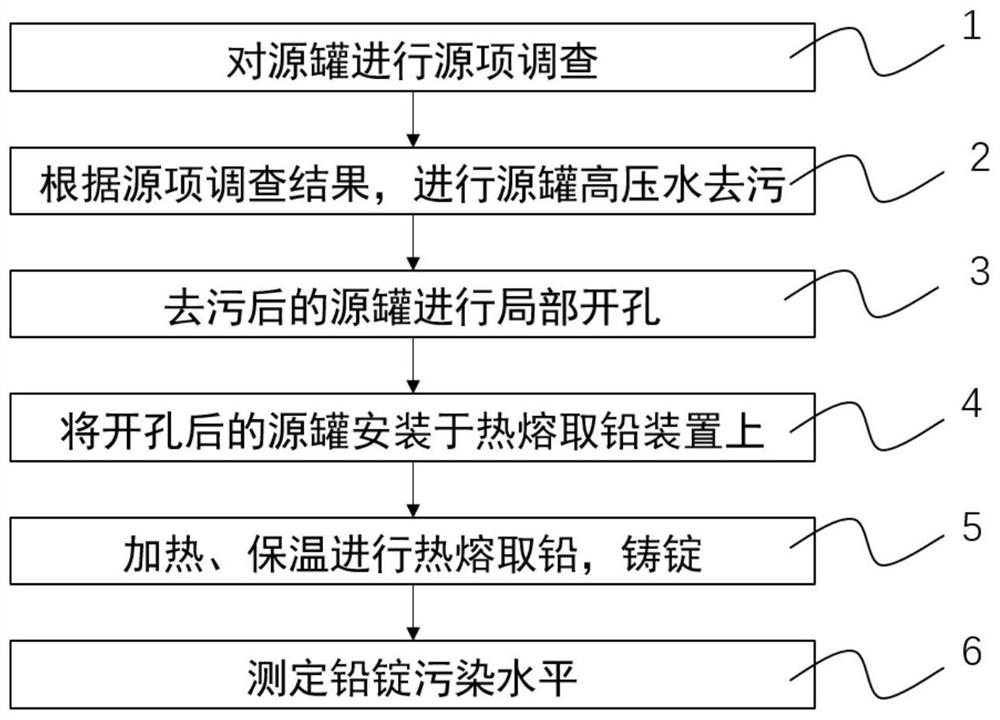

Method used

Image

Examples

Embodiment 1

[0035] The source item of the No. 1 source tank was measured, the weight was 1244Kg, the α surface pollution level was not detected, and the β surface pollution level was 31.6Bq / cm 2 , Part of the paint on the surface of the source tank is peeling off. Due to surface contamination level 2 , so open high-pressure water is used for flushing and decontamination, the flushing pressure of high-pressure water is 110Mpa, and the flushing time is 7min. The source tank is blown dry with compressed air, and holes are drilled from the bottom of the source tank. The radioactive waste generated by the hole is tested and put into steel drums for disposal. Install the No. 1 source tank after opening the hole in a hot-melt lead extraction device with an industrial natural gas furnace as the heat source, control the temperature of the tank body at 360-370°C, and heat for 2 hours. After the lead is completely melted and separated from the source tank body, it enters the container In the proces...

Embodiment 2

[0038] The source item of the No. 2 source tank was measured, the weight was 2056Kg, the α surface pollution level was not detected, and the β surface pollution level was 56.1Bq / cm 2 , The paint on the surface of the source tank is more peeled off. Due to surface contamination level > 40Bq / cm 2 , so closed high-pressure water is used for flushing and decontamination, the flushing pressure of high-pressure water is 120Mpa, and the flushing time is 12min. The source tank is blown dry with compressed air, and holes are drilled from the bottom of the source tank. The radioactive waste generated by the hole is tested and put into steel drums for disposal. Install the No. 2 source tank after opening the hole in a hot-melt lead extraction device with an industrial natural gas furnace as the heat source, control the temperature of the tank body at 360-370°C, heat for 4.5 hours, and wait until the lead is completely melted and separated from the source tank body to enter the container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com