Automatic frost spraying device for automobile defrosting test and control method

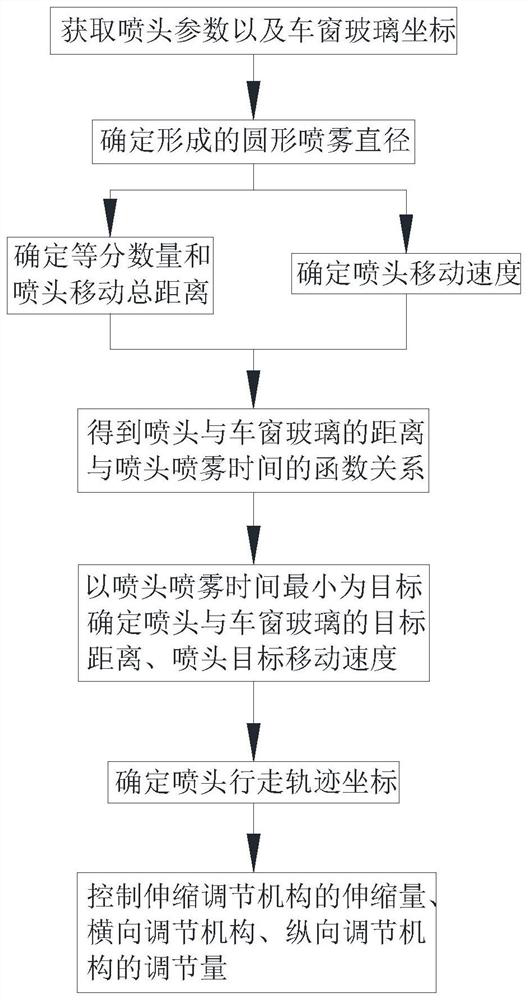

A control method and automatic technology, applied in the direction of spraying device, measuring device, vehicle test, etc., can solve the problems of inability to ensure spray uniformity and work efficiency, and achieve the effect of shortening time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] DETAILED DESCRIPTION OF THE PREFERRED DESCRIPTION OF THE PREFERRED DESCRIPTION OF THE PREFERRED DESCRIPTION OF THE PREFERRED DESCRIPTION OF THE PREFERRED DESCRIPTION OF THE PREFERRED DESCRIPTION OF THE PREFERRED EMBODIMENTS A detailed description of the invention will be more apparent to those skilled in the art. The scope of protection of the present invention is not limited to the following specific embodiments. It is also the scope of the invention in the following detailed description of the invention.

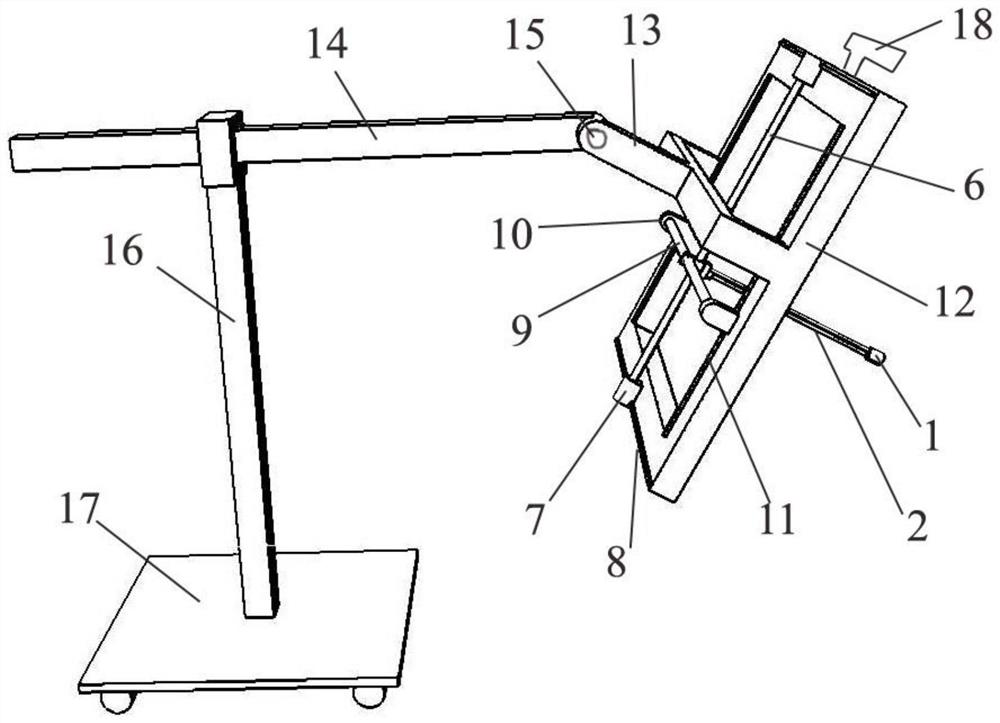

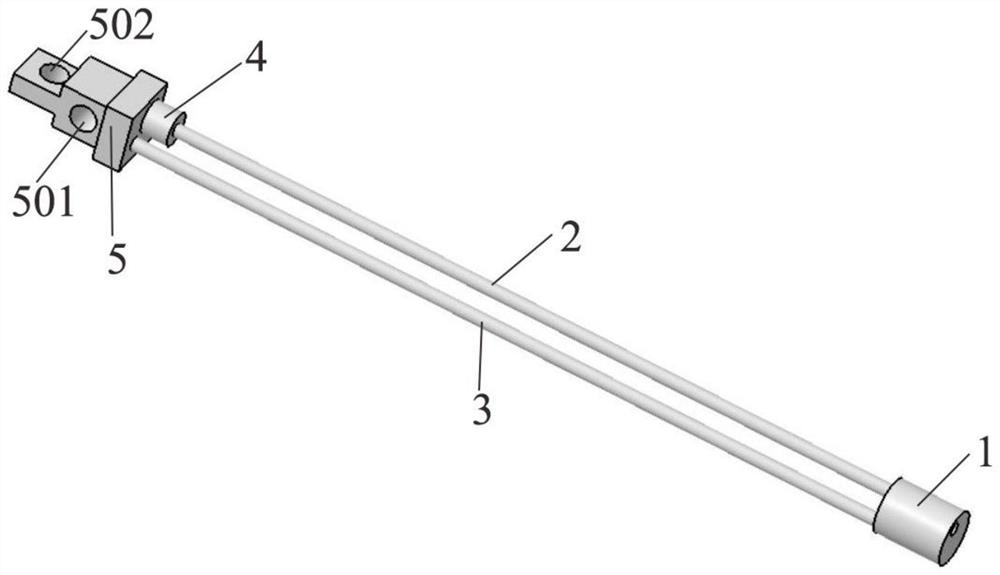

[0034] Such as Figure 1 ~ 2As shown, a car defrosting test automatic filamenting device, including nozzle 1, nozzle 1 through the telescopic adjustment mechanism and nozzle connecting seat 5, nozzle connecting seats, portrait, longitudinal adjustment mechanism, and lateral adjustment mechanism, longitudinal adjustment mechanism and horizontal direction The adjustment mechanism is slidably fitted with the frame 12, and the frame 12 is connected to the fixed bracket throu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap