Horizontal coring drilling machine

A horizontal and drilling rig technology, applied in the direction of rotary drilling rig, drill pipe, drill pipe, etc., can solve the problems of difficult implementation, high comprehensive cost, large drilling volume, etc., and achieves reduction of invalid footage, low engineering cost, and comprehensive efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

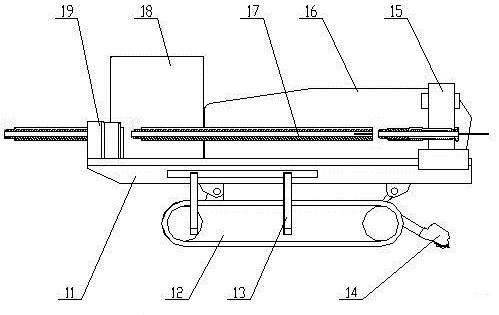

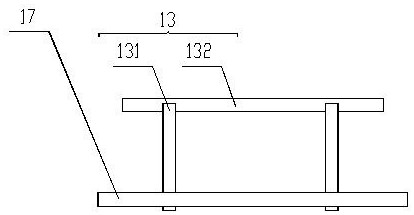

[0022] Such as figure 1 A horizontal coring drilling machine shown includes a drill frame 11, a chassis 12 is hinged below the drill frame 11, and legs 14 are arranged on the chassis 12, and a power head assembly is arranged on the top of the drill frame 11 in sequence. 15, machine cover 16, drill pipe 17, driver's cab 18 and vise 19, the side of described drill stand 11 is provided with drill pipe loading and unloading device 13. The horizontal core drilling rig of the present invention comprises a drill frame 11, a chassis 12, a drill rod loading and unloading device 13, a leg 14, a power head assembly 15, a machine cover 16, a drill rod 17, a cab 18 and a vise 19, and the drill frame It is used to install the power head assembly, vise and adjust the working angle of the whole machine; the chassis is used to carry the weight of the whole machine and drive the whole machine to walk, and the drill pipe loading and unloading device is used to realize the transmission of drill p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com