Flying saucer type no-net filtering slag pressing machine

A technology of meshless filtration and slag press, which is used in filtration and separation, mobile filter element filters, separation methods, etc., can solve the problems of small particle diameter requirements and high water content of sediment, and achieve low operating costs and water in slag output. The effect of low rate and less wearing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

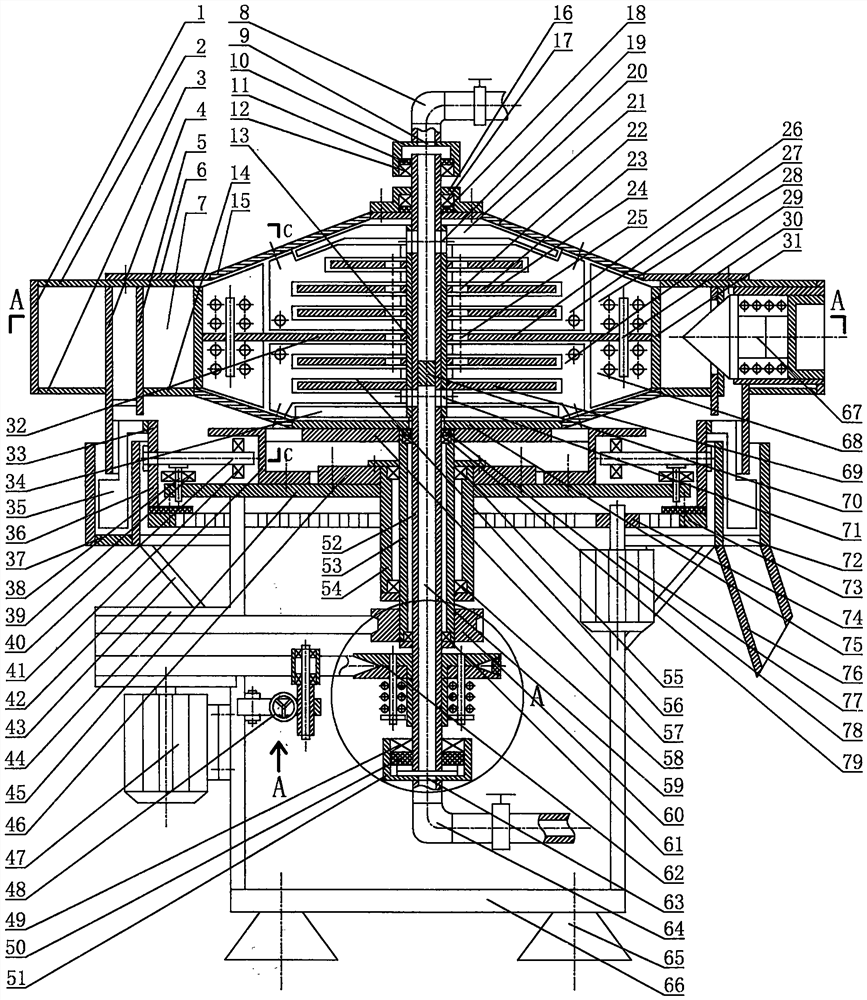

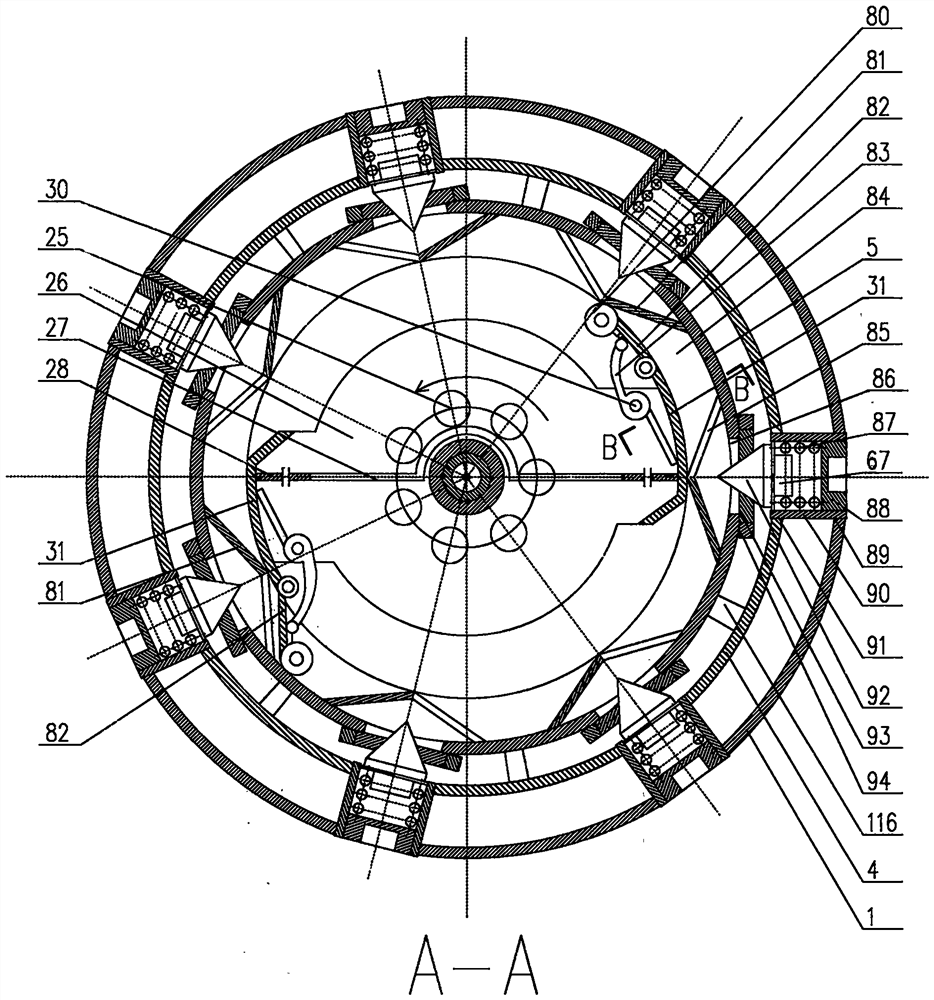

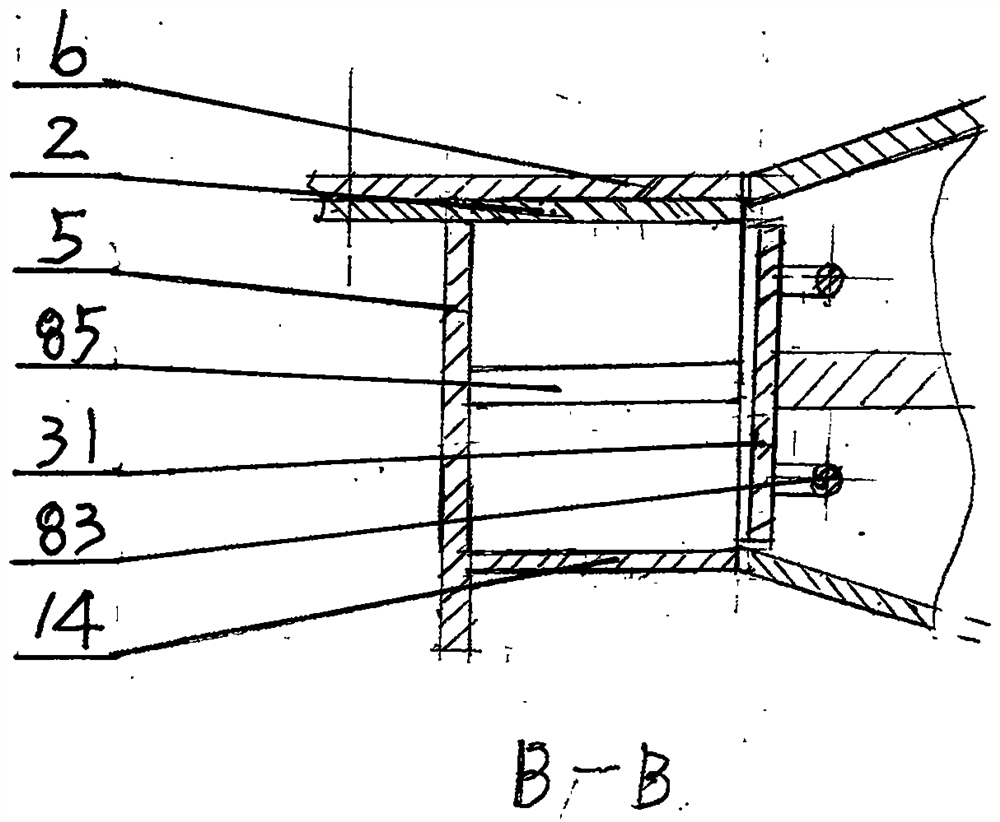

[0038] Below in conjunction with the accompanying drawings, the embodiments of the flying saucer type meshless filter slag press of the present invention are described in detail:

[0039] The flying saucer type meshless filter slag press of the present invention is composed of a frame 66, a drive motor 47, a high-speed differential device 59, a flying saucer-type drum 21, a solid-liquid separation system 32, a slag scraping device, a slag discharge system, a deceleration motor 76, The slag discharge system 33, the water inlet and the water outlet are constituted: the frame 66 is provided with a drive motor 47, and the base plate 45 at the upper end of the frame 66 is provided with a high-speed differential device 59, which is driven by the drive motor 47 to rotate at a differential speed Operation, a flying saucer-type rotating drum 21 is arranged above the high-speed differential device 59, and the rotating operation is driven by the high-speed differential device 59. The dru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com