Novel single-Dewar high-efficiency motor structure

A motor structure, single Dewar technology, applied in the direction of magnetic circuit shape/style/structure, electromechanical devices, electrical components, etc., can solve the problems of large amount of liquid nitrogen consumption, long refrigeration time, high motor cost, etc., to reduce the amount of consumption, process Simple and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

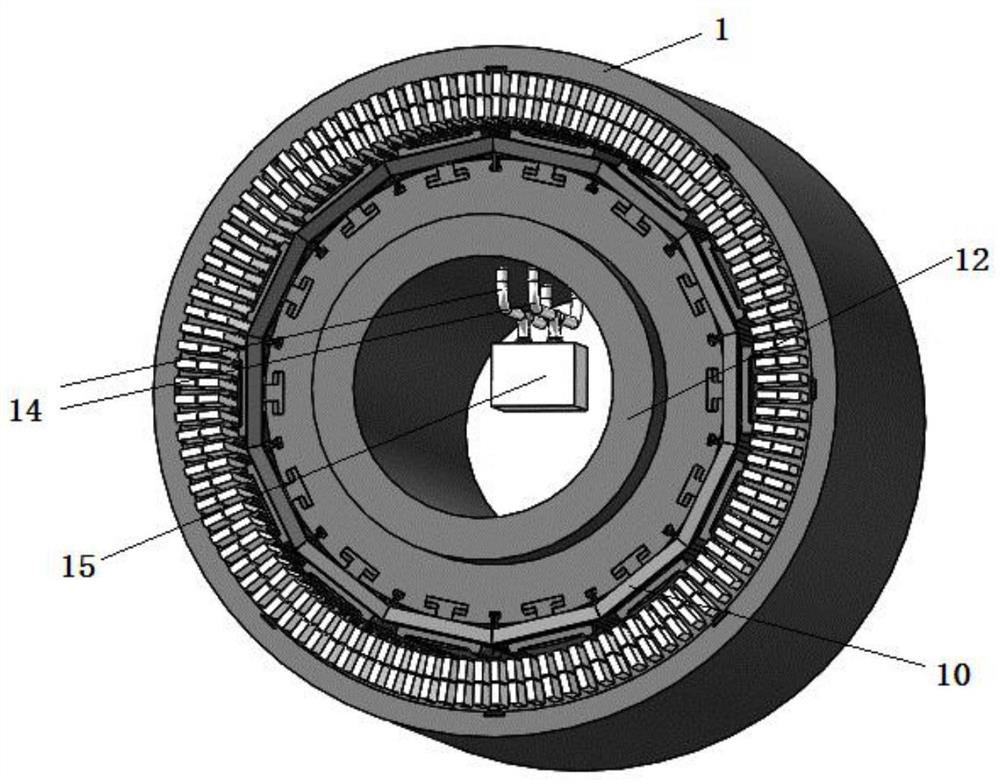

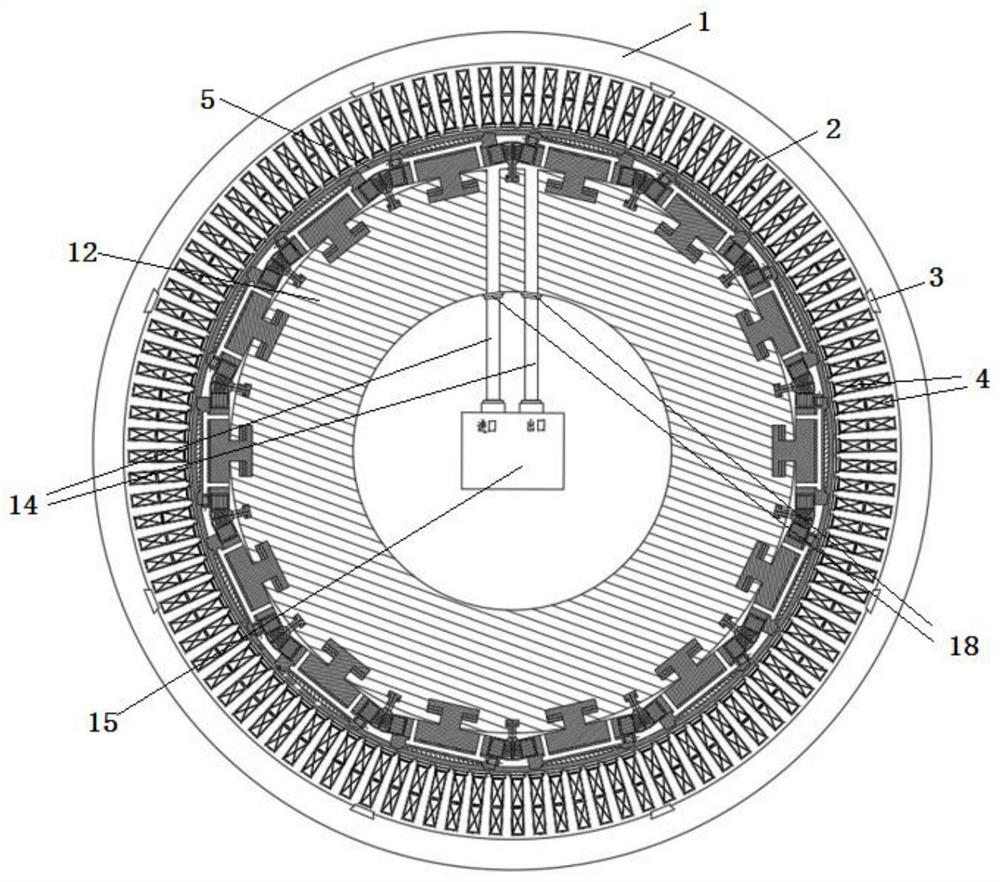

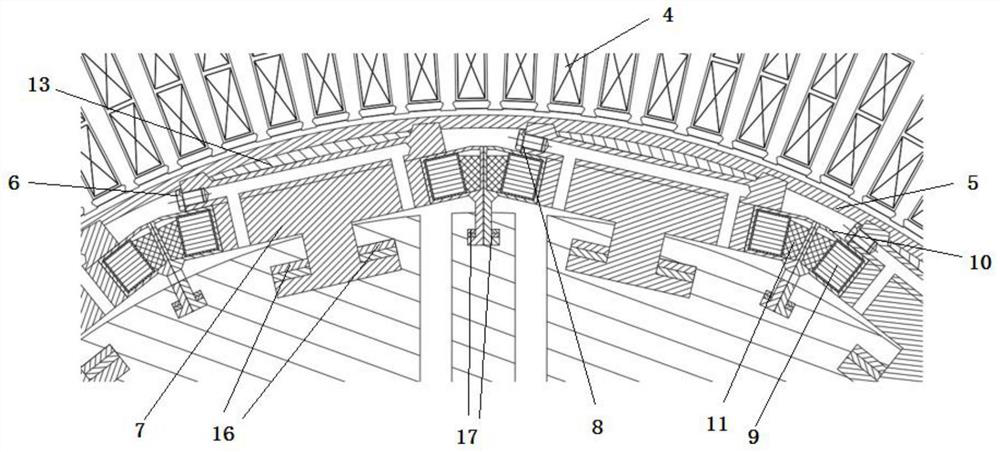

[0036] Such as figure 1 , 2 , 3, a new single Dewar high-efficiency motor structure consists of a stator yoke 1, a stator tooth 2, a dovetail key 3, a stator winding 4, a Dewar sleeve 5, a plug 6, a rotor core 7, a stopper Moving gasket 8, excitation coil 9, coil support 10, coil stopper 11, rotating shaft 12, copper shielding block 13, coolant circulation pipe 14, cooler 15, rotor core oblique key 16, coil support oblique key 17 , sealing ring 18; the stator yoke 1 is connected to the stator teeth 2 through the dovetail key 3, the stator windings 4 are respectively placed in the slots between the stator teeth 2, and the Dewar sleeve 5 is arranged on the stator teeth 2 Inside, there is a 5mm air gap between the Dewar sleeve 5 and the stator teeth 2. The rotor cores 7 are arranged inside the Dewar sleeve 5 and distributed along the circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com