Self-heating battery thermal management control device, battery assembly, electric vehicle and method

A battery thermal management and control device technology, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve problems such as the inability to realize efficient cooling of power batteries, automatic heating of battery packs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

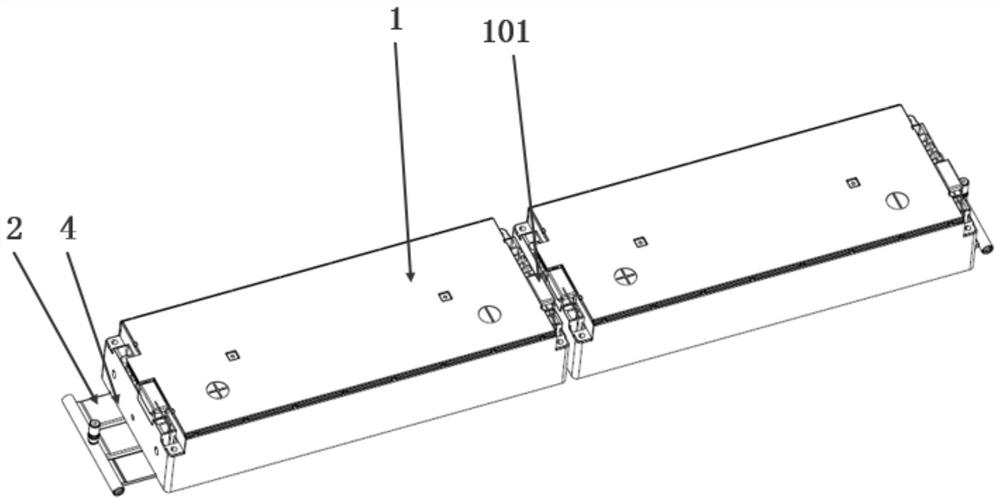

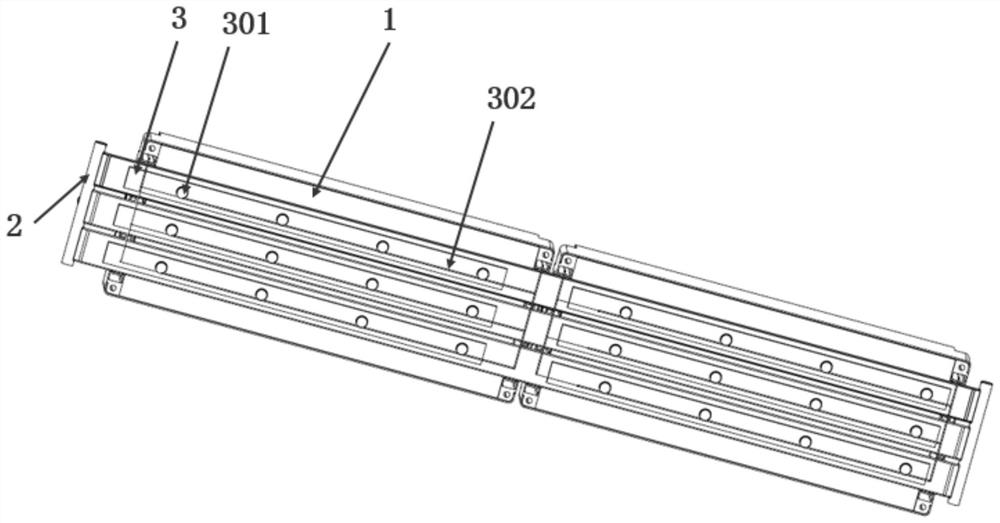

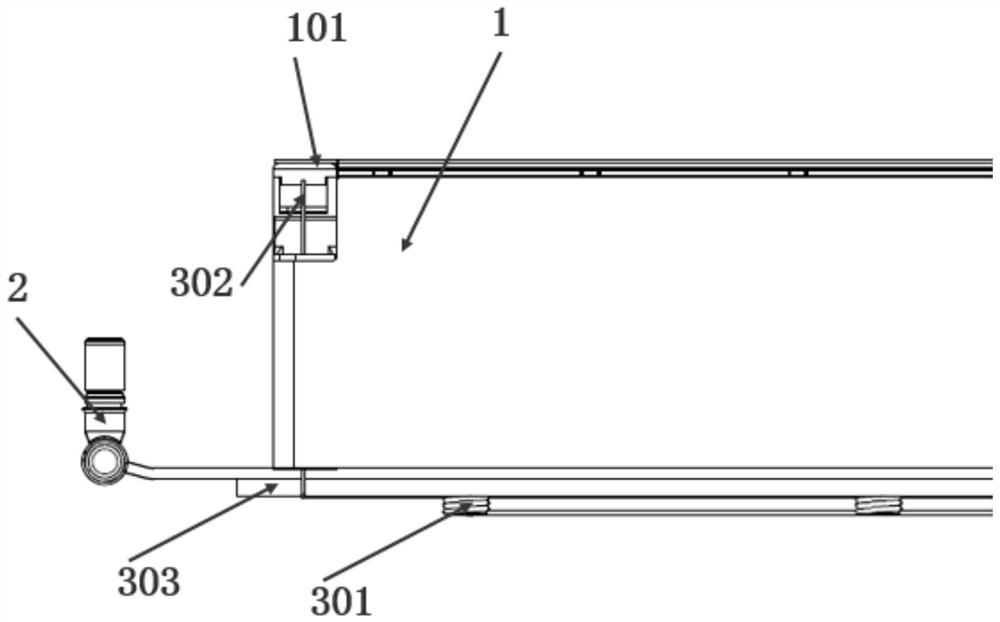

[0057] refer to figure 1 , figure 2 with Figure 4 , a thermal management control device for a self-heating battery, comprising a battery module 1 , a cooling system 2 , a self-heating system 3 and a heat conduction structure 4 .

[0058] The battery module 1 is placed inside the battery pack. The positive and negative poles of the battery module 1 are provided with switch positive and negative poles 101; the positive and negative poles of the switch 101 contain IGBT switches; the IGBT switches are connected to the battery BMS. The battery BMS is mainly responsible for signal collection of the battery module 1 and controls the battery module 1 .

[0059] The cooling system 2 is arranged at the lower end of the battery module 1 .

[0060] The self-heating system 3 is fixed at the lower end of the cooling system 2, and is connected to the positive and negative poles of the battery module 1 in a loop;

[0061] refer to figure 2 with image 3 , the self-heating system 3 i...

Embodiment 2

[0070] This embodiment provides a battery assembly, including the self-heating battery thermal management control device in Embodiment 1. The battery assembly adopts a self-heating battery thermal management control device in Embodiment 1. Through the self-heating system, the efficient cooling of the battery assembly and the automatic heating function of the battery pack are realized, and the overall thermal management efficiency of the battery assembly is improved.

Embodiment 3

[0072] This embodiment provides an electric vehicle, including the battery assembly in the second embodiment. The battery assembly adopts the self-heating battery thermal management control device and self-heating system in Embodiment 1 to realize the efficient cooling of the battery assembly and the automatic heating function of the battery pack, which improves the overall thermal management efficiency of the battery assembly, thereby effectively ensuring The safety of electric vehicles reduces the cost of research and development.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com