Thin film capacitor

A film capacitor and capacitor technology, applied in the field of capacitors, can solve the problems of increased heat generation and smaller heat dissipation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

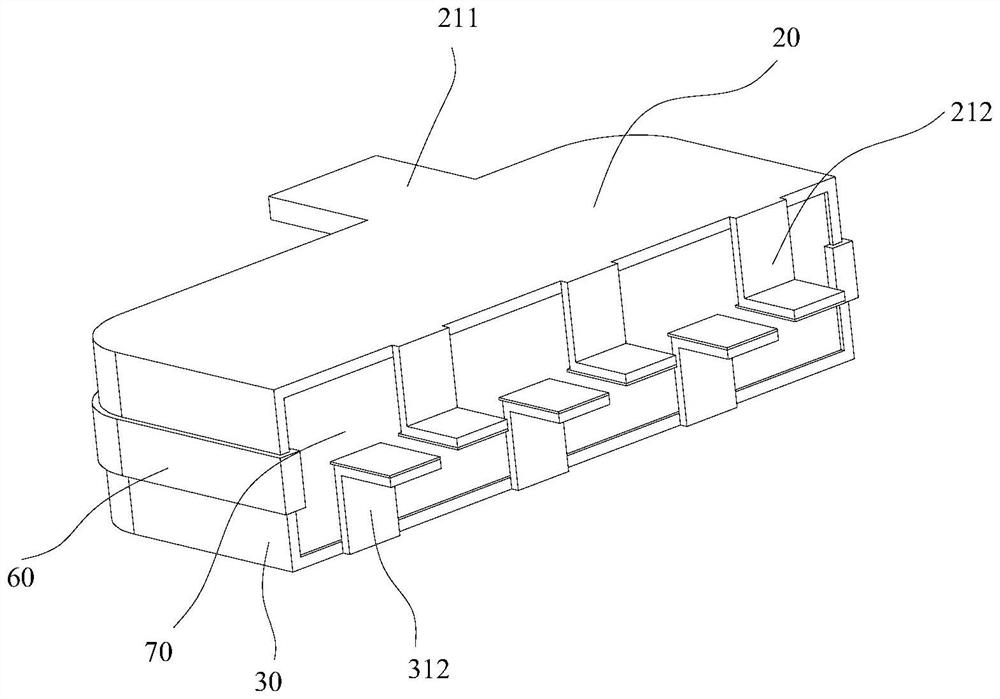

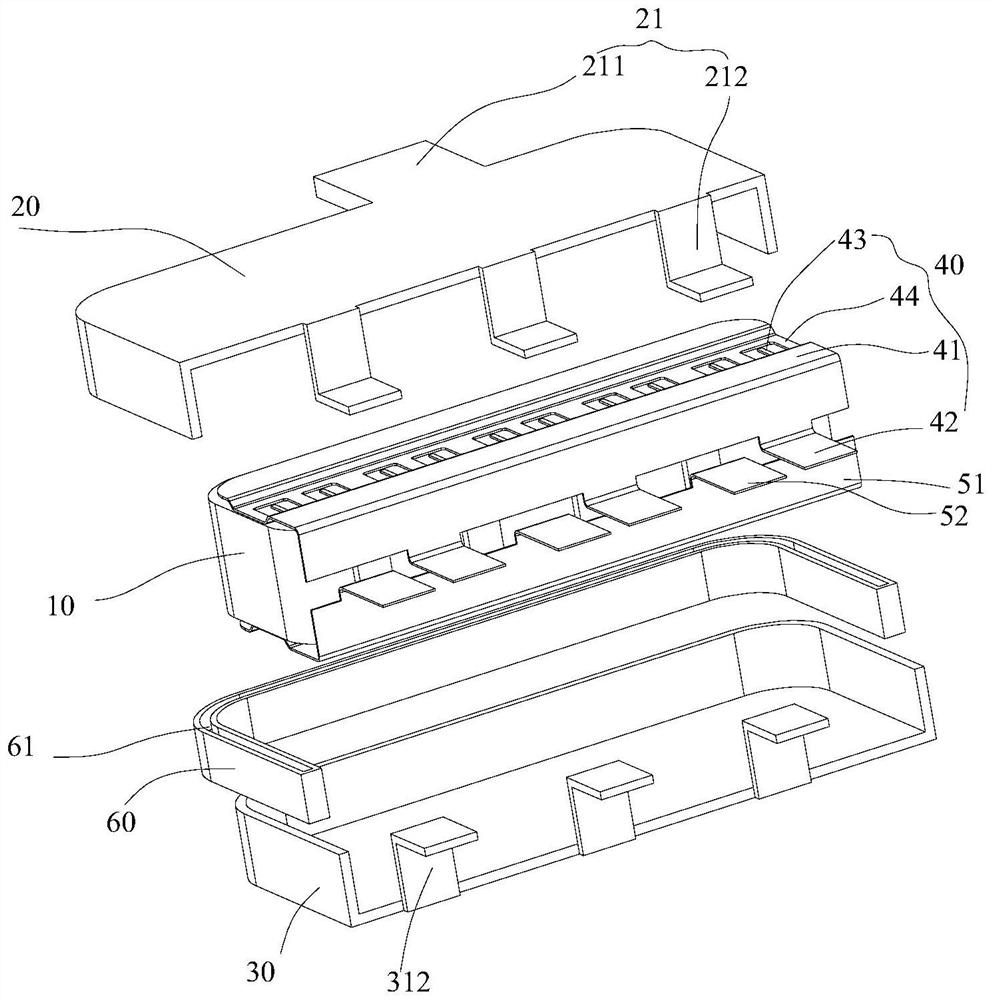

[0041] Such as Figure 1 to Figure 4 As shown, the film capacitor according to the embodiment of the present invention includes a capacitor core 10 , at least one first metal shell 20 , at least one second metal shell 30 , a first connection piece 40 and a second connection piece 50 .

[0042] Specifically, the first metal shell 20 and the second metal shell 30 are spliced together through the insulator 60 to jointly define the accommodation cavity H; the first metal shell 20 is provided with a first lead-out terminal 21 , and the second metal shell The body 30 is provided with a second lead-out terminal 31; the first connecting piece 40 is connected with the capacitor core 10 and the first metal shell 20; the second connecting piece 50 is connected with the capacitor core 10 and the second metal shell 30; the capacitor The core 10 , the first connecting piece 40 and the second connecting piece 50 are arranged in the containing cavity H and sealed by a potting glue 70 .

[...

Embodiment 2

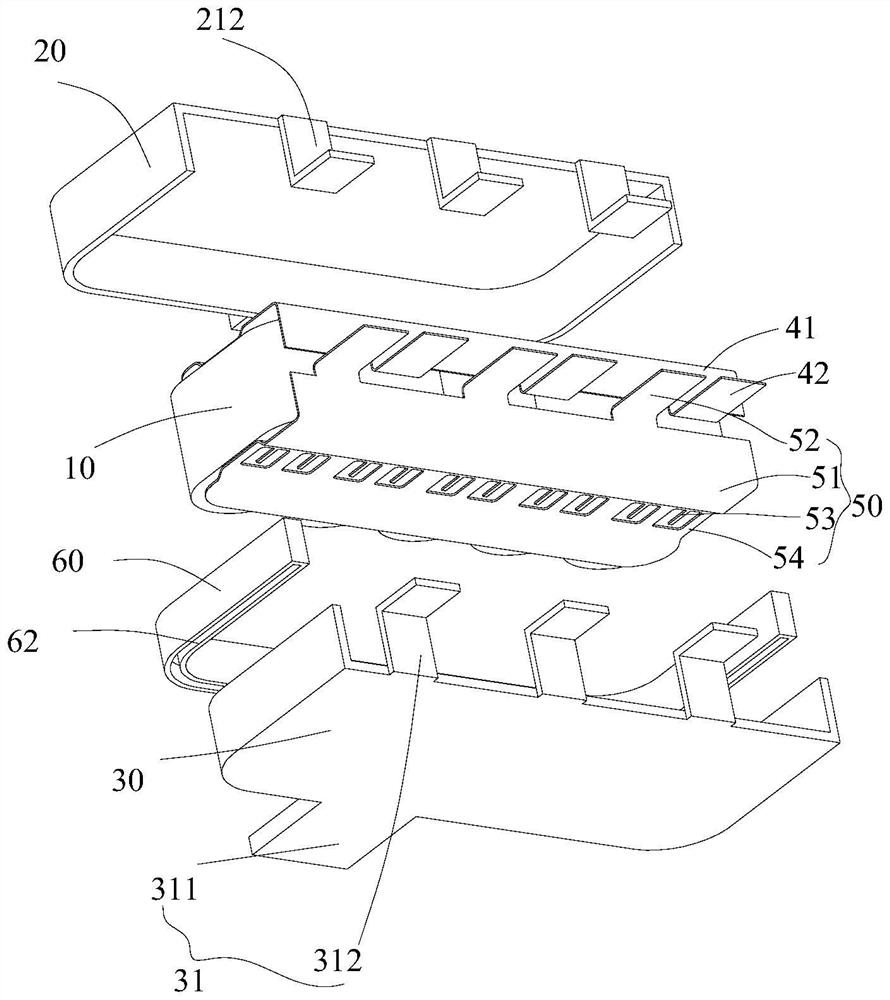

[0065] The structure and principle of this embodiment are roughly the same as those of the embodiment, the same place will not be described in detail, the difference is that in combination Figure 5 with Figure 6 , the arrangement of multiple cores in the capacitor core 10 is that the end faces are facing forward and backward, horizontally side by side, the first connecting piece body 41 of the first connecting piece 40 is L-shaped, and the first connecting terminal 42 is arranged on On the short limbs of the first connecting piece body 41 of the L shape, the long limbs of the first connecting piece body 41 of the L shape are arranged horizontally, so that the first connecting terminal 42 can be welded with the gold-sprayed surface of the capacitor core 10, and The connecting terminal is relatively soft, has a certain degree of plasticity, and is not easy to accumulate stress. When the connecting terminal is welded to the gold-sprayed surface, the welding point is on the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com