Corrected PID temperature control method

A temperature control method and controller technology, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve problems such as overshoot and temperature reverse regulation, and achieve convenient maintenance and use, cost reduction, and reliability. good readability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

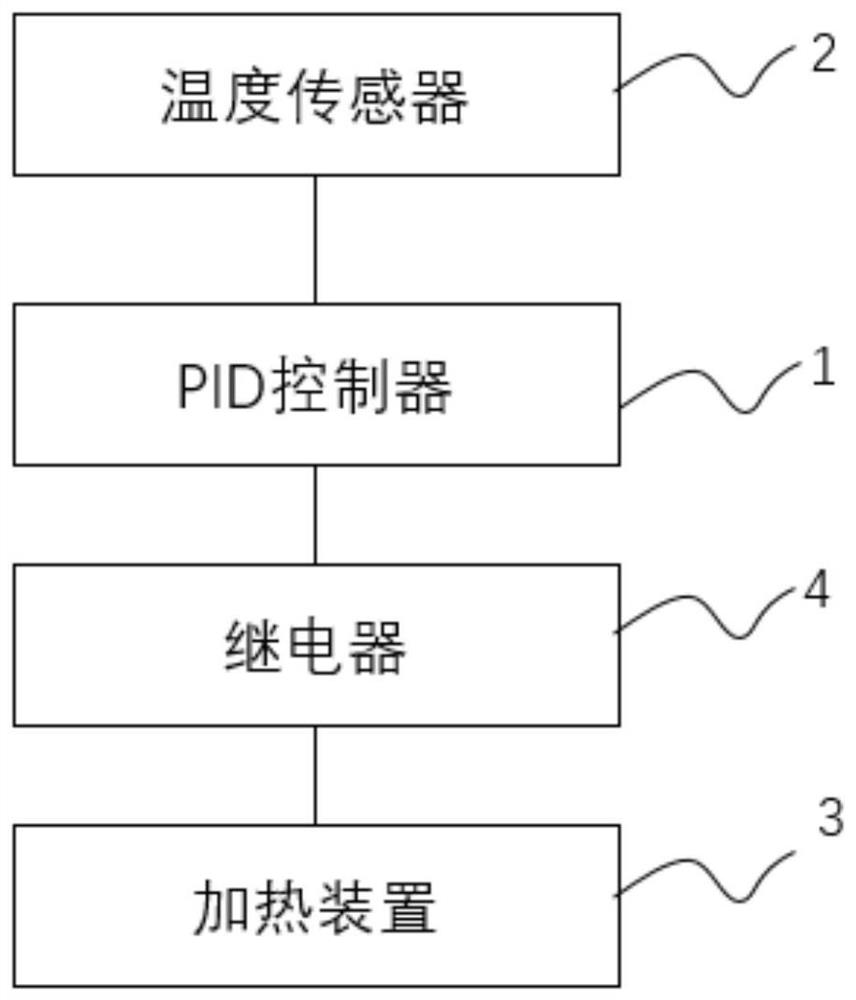

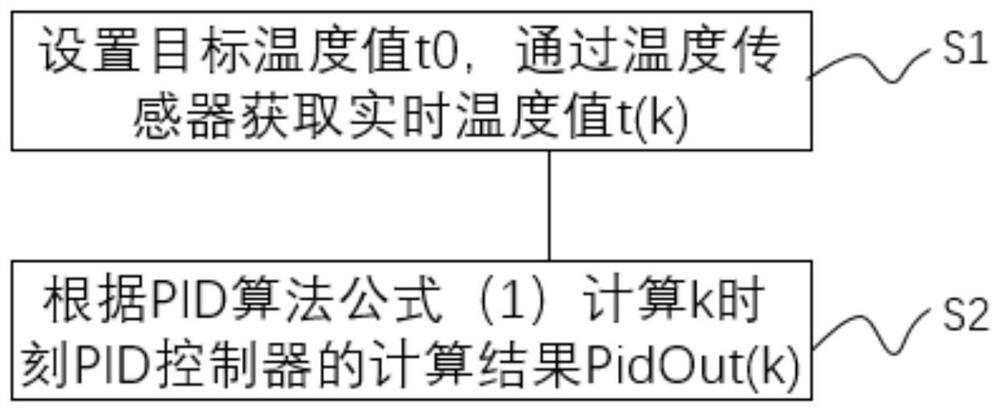

[0095] see figure 2 As shown, the embodiment of the present application provides a modified PID temperature control method, which is applied to the above-mentioned PID temperature control system, including:

[0096] S1, set the target temperature value t 0 , get the real-time temperature value t through the temperature sensor (k) ;

[0097] S2, calculate the calculation result PidOut of the PID controller at time k according to the PID algorithm formula (1) (k) .

[0098] The PID algorithm formula (1) is as follows:

[0099]

[0100] in,

[0101] K p is the proportional coefficient, which is obtained by data modeling calculation or its empirical value obtained according to the experimental method;

[0102] K i is the integral coefficient, which is calculated by data modeling or its empirical value is obtained according to the experimental method;

[0103] e (k) is the deviation between the target temperature value and the real-time temperature value at time k;

...

Embodiment 2

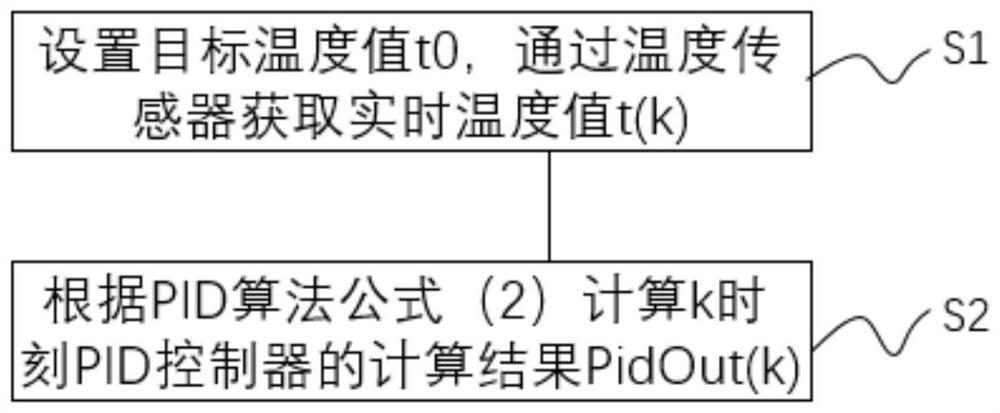

[0130] see image 3 As shown, the embodiment of the present application also provides a modified PID temperature control method, which is applied to the above-mentioned PID temperature control system, and the method includes:

[0131] S1, set the target temperature value t 0 , get the real-time temperature value t through the temperature sensor (k) ;

[0132] S2, calculate the calculation result PidOut of the PID controller at time k according to the PID algorithm formula (2) (k) .

[0133] The PID algorithm formula is as follows:

[0134]

[0135] in,

[0136] K p is the proportional coefficient, which is obtained by data modeling calculation or its empirical value obtained according to the experimental method;

[0137] K i is the integral coefficient, which is calculated by data modeling or its empirical value is obtained according to the experimental method;

[0138] e (k) is the deviation between the target temperature value and the real-time temperature value...

Embodiment 3

[0168] The embodiment of the present application also provides a modified PID temperature control method, which is applied to the above-mentioned PID temperature control system, and the method includes:

[0169] Set the target temperature value t 0 , get the real-time temperature value t through the temperature sensor (k) ;

[0170] Calculate the calculation result PidOut of the PID controller at time k according to the PID algorithm formula (1) (k) , the formula is as follows:

[0171]

[0172] in,

[0173] K p is the proportional coefficient, which is obtained by data modeling calculation or its empirical value obtained according to the experimental method;

[0174] K i is the integral coefficient, which is calculated by data modeling or its empirical value is obtained according to the experimental method;

[0175] e (k) is the deviation between the target temperature value and the real-time temperature value at time k;

[0176] A is the suppression parameter.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com