Calibration water outlet setting method of quantitative water outlet faucet, water outlet method and faucet

A faucet and water output technology, which is applied in the direction of measuring devices, valve devices, mechanical equipment, etc., can solve the problems that affect consumer satisfaction, cumbersome maintenance process, and long maintenance cycle, so as to improve satisfaction, simplify operation steps, Accurate effect of effluent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

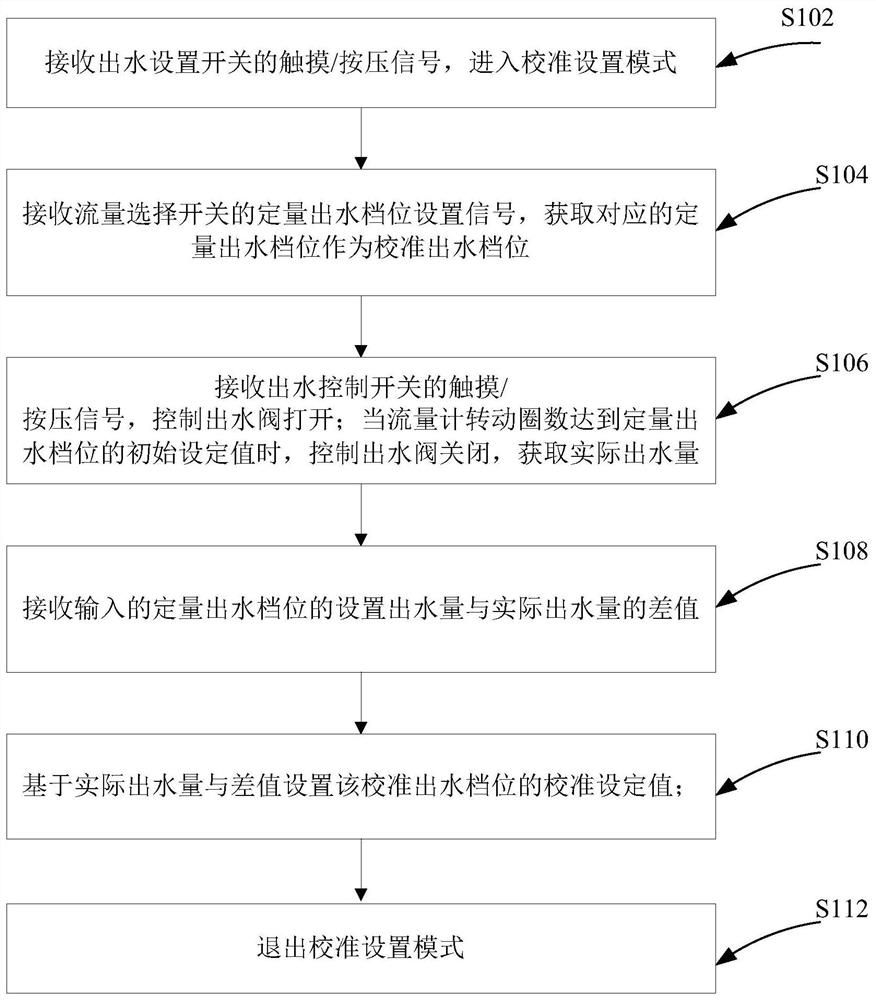

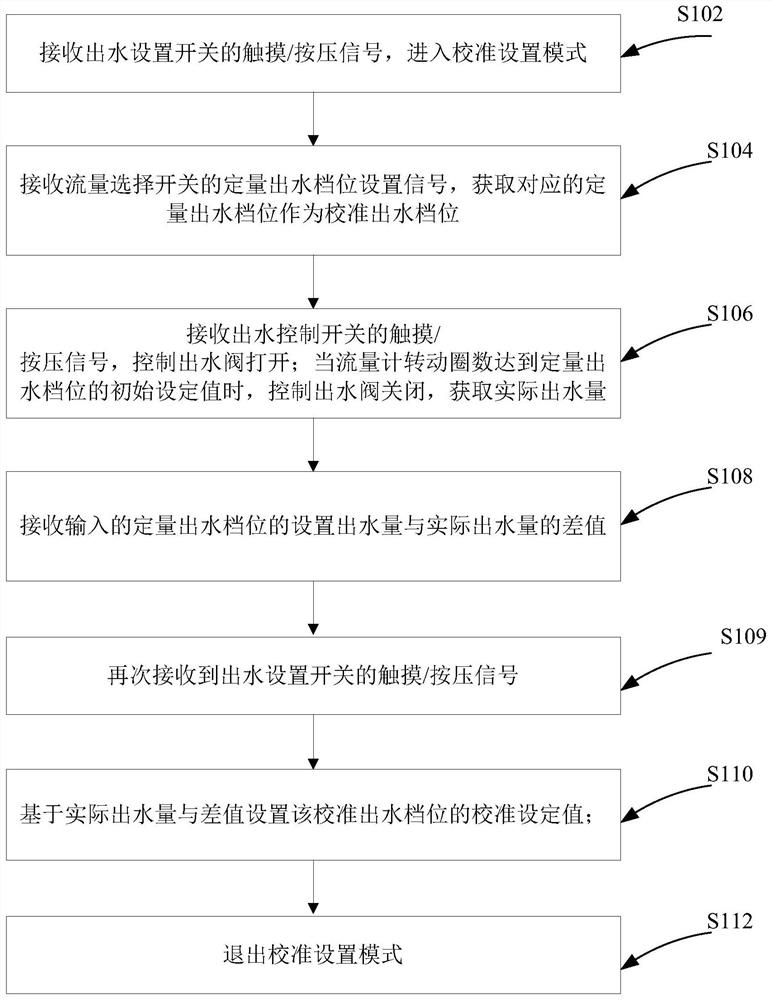

[0070] see figure 1 As shown, the present invention provides a method for calibrating water outlet setting of a quantitative outlet faucet, comprising:

[0071] S102, receiving the touch / press signal of the water outlet setting switch, and entering the calibration setting mode;

[0072] S104, receiving the quantitative water outlet gear setting signal of the flow selection switch, and obtaining the corresponding quantitative water outlet gear as the calibration water outlet gear;

[0073] S106, receiving the touch / press signal of the water outlet control switch, controlling the water outlet valve to open; when the number of rotations of the flowmeter reaches the initial setting value of the quantitative water outlet gear, controlling the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com