Capacitive two-dimensional force sensor

A sensor and capacitive technology, applied in the field of sensors, can solve the problems of time-consuming and labor-intensive production, and achieve the effects of improving sensitivity and accuracy, preventing measurement errors, and facilitating detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The terminology used herein is for the purpose of describing particular embodiments only and is not intended to be limiting of the invention. Unless otherwise defined, all terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs. It will be further understood that commonly used terms should be interpreted to have a meaning consistent with their meaning in the relevant art and this disclosure. This disclosure is to be considered as an example of the invention and is not intended to limit the invention to the particular embodiments.

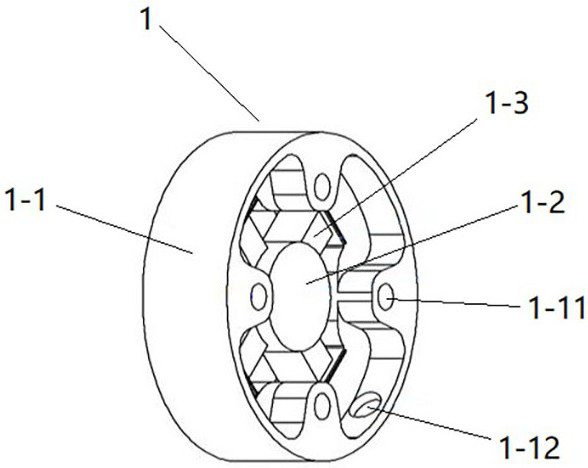

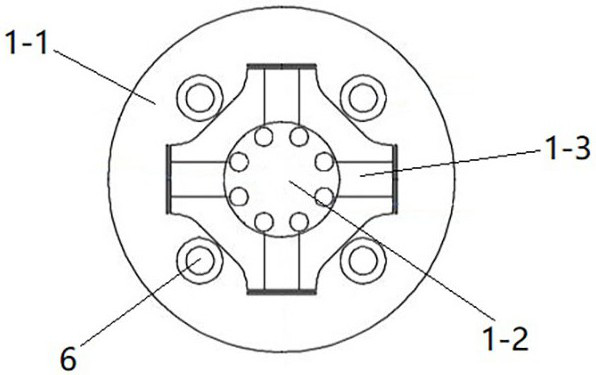

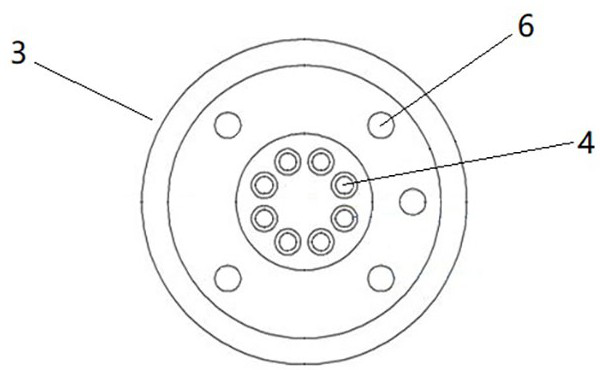

[0031] This embodiment provides a capacitive two-dimensional force sensor, such as figure 1 , figure 2 ,, Figure 5 , including a strain structure 1, the strain structure 1 includes a fixed shell 1-1 arranged at the periphery, a strain table 1-2 located at the center, connected between the strain table 1-2 and the fixed shell 1- The elastic member 1-3 between 1 al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com