Efficient intelligent air compressor water leakage detection auxiliary equipment

An auxiliary equipment, air compressor technology, applied in mechanical equipment, pump testing, machine/engine, etc., can solve the problems of unstable signal of audiometer, lower success rate of fixed point, increase probability of broken bricks, etc., to improve automatic Control cycle, improve work efficiency, improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

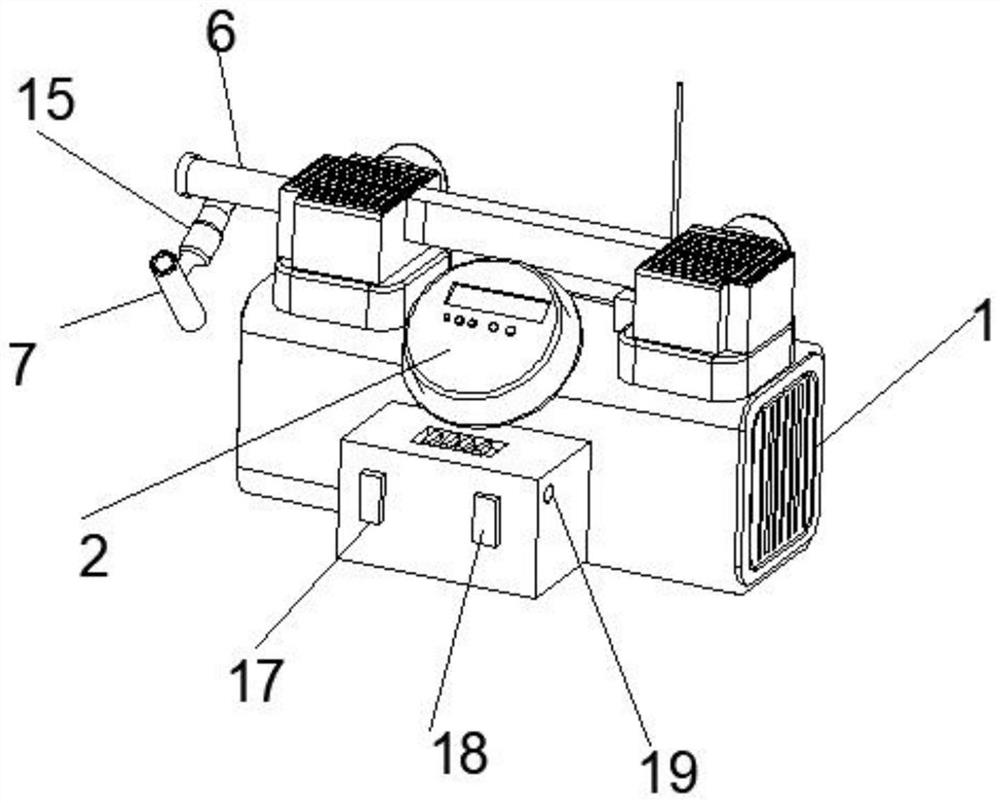

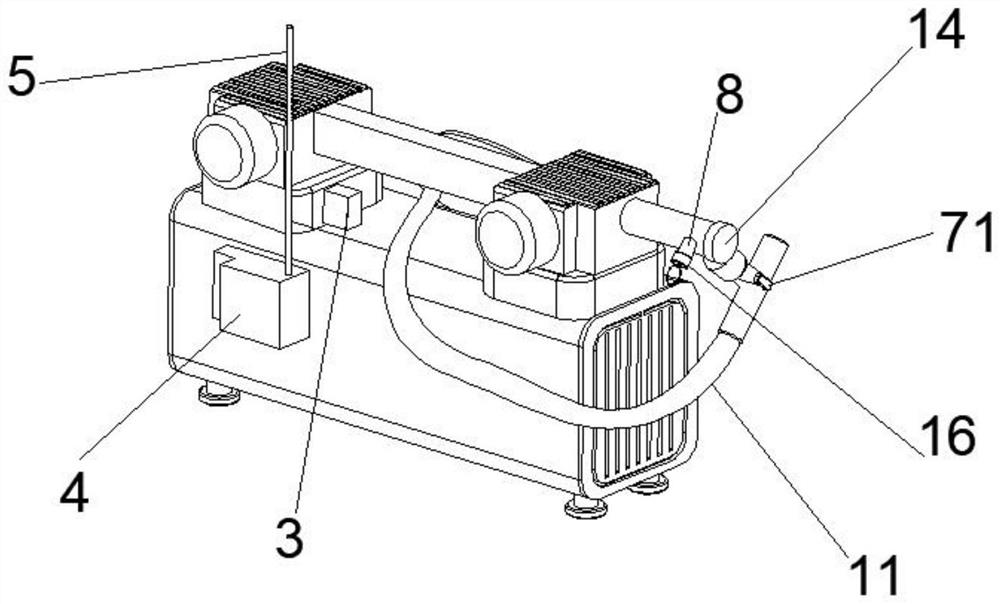

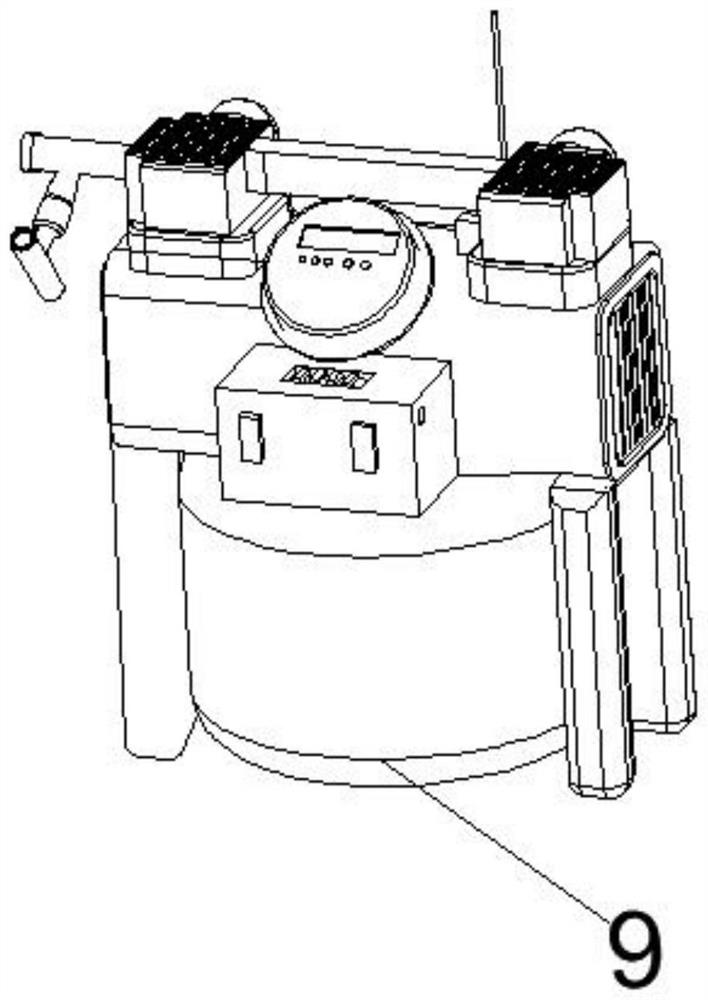

[0029] refer to Figures 1 to 11, a high-efficiency intelligent air compressor water leakage detection auxiliary equipment, including an air pump body 1, an air storage tank 9, the air pump body 1 is a permanent magnet variable frequency air compressor. The air pump body 1 is provided with a digital display pressure controller 2 for controlling gas pressure, a relay 3 for controlling the circuit of the digital display pressure controller 2, and a remote control receiver 4 for remotely starting and stopping the air pump body 1. The device 4 is provided with a foldable antenna 5, the air pump body 1 is connected with a tee 7 on the outlet pipe 6, the free end of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com