Sliding supporting device for supporting heavy pressure vessel

A pressure vessel, sliding support technology, applied in the direction of pressure vessel, vessel discharge method, vessel filling method, etc., can solve problems such as separate setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

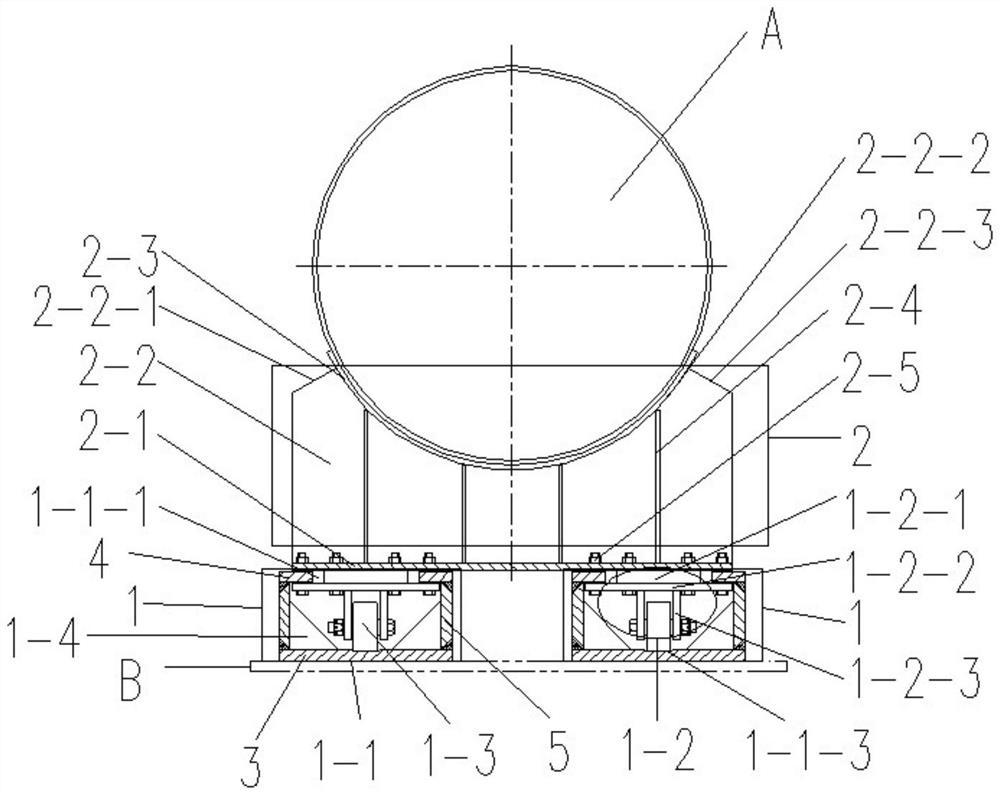

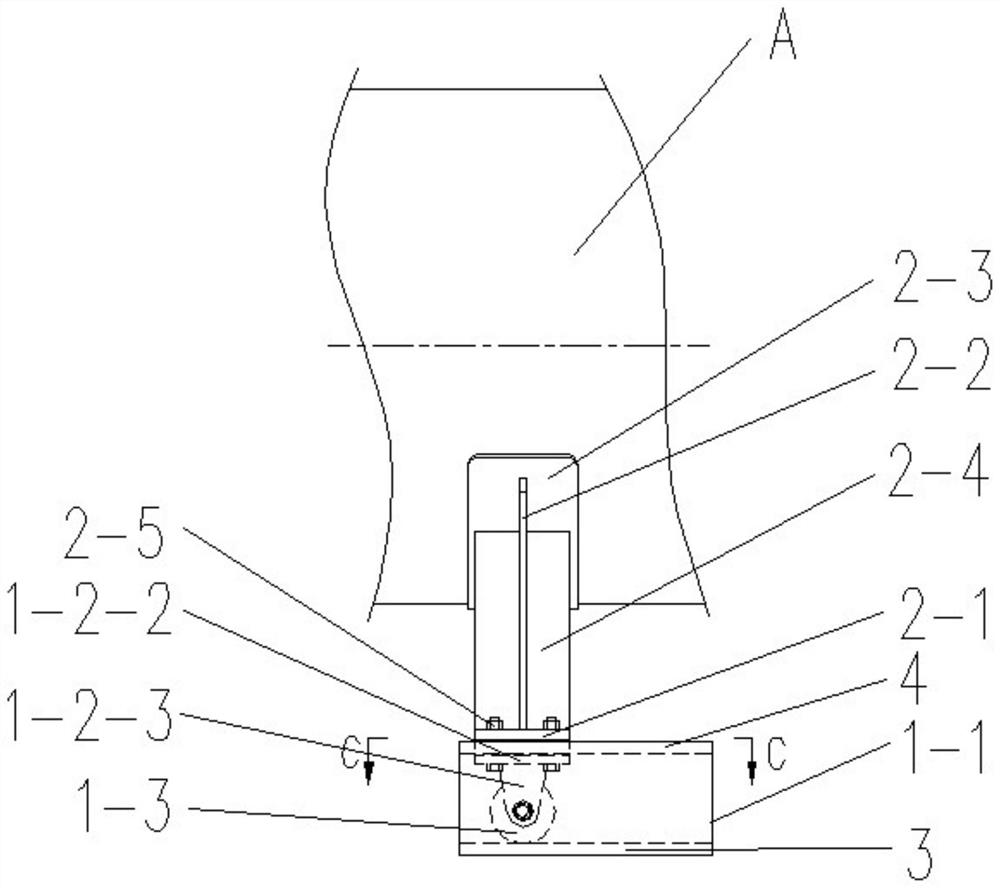

[0011] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, a sliding support device for supporting a heavy pressure vessel in this embodiment, it includes a sliding device and a support 2, the support 2 is slidably installed on the upper surface of the sliding device, and the support 2 is used to install a heavy pressure vessel. The container A, the support 2 is made of steel plate, and the heavy pressure vessel A is installed on the support 2;

[0012] The sliding device includes a plurality of sliding assemblies 1, the number of the plurality of sliding assemblies 1 is two, and the two sliding assemblies 1 are distributed at both ends of the support 2, which can ensure the force balance of the support 2 during use, and each sliding Components 1 all include box body 1-1, connection assembly 1-2 and pulley 1-3, and each connection assembly 1-2 is all installed in each box body 1-1, and each pulley 1-3 is all rotatably installed on The middle...

specific Embodiment approach 2

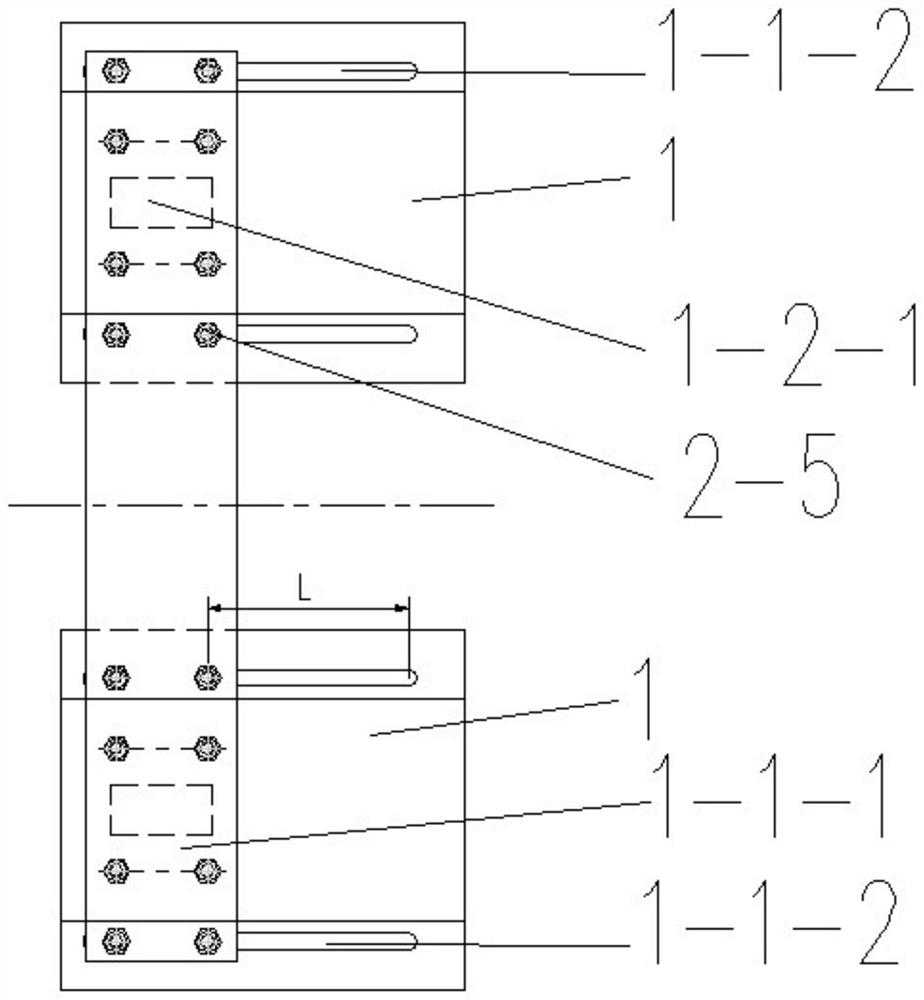

[0014] Specific implementation mode two: combination Figure 1-Figure 3 Describe this embodiment, a sliding support device for supporting a heavy-duty pressure vessel described in this embodiment, the center position of the upper surface of each box 1-1 is provided with a rectangular opening 1-1-1 along the length direction, and the rectangular opening 1-1-1 is used to install backing plate 1-2-1, and the length of each rectangular opening 1-1-1 is equal to the length of each rectangular box body, and the width of each rectangular opening 1-1-1 is It is smaller than the width of each rectangular box, so it is set to ensure that a part of the box is reserved on both sides of the rectangular opening 1-1-1 of each box 1-1 to connect the support 2 with the sliding assembly 1, and each rectangular opening 1 Waist-shaped through holes 1-1-2 are processed on the upper surfaces of the remaining boards on both sides of -1-1 along the length direction. Others are the same as in the fir...

specific Embodiment approach 3

[0015] Specific implementation mode three: combination Figure 1-Figure 3 Describe this embodiment, a sliding support device for supporting a heavy-duty pressure vessel described in this embodiment, each box 1-1 includes a lower bottom plate 3, two cover plates 4 and four vertical plates 5, each box The connection between the lower bottom plate 3, the two cover plates 4 and the four vertical plates 5 of 1-1 are all formed by welding to form the box body 1-1, each lower bottom plate 3 and each vertical plate 5 are rectangular plates, The surface of each lower bottom plate 3 should be guaranteed to be level and smooth without jamming. The four vertical plates 5 are respectively fixedly installed on the four sides of the upper surface of each lower base plate 3, and the upper surface of each cover plate 4 is provided with a waist-shaped through hole 1-1-2, and the two cover plates 4 are fixed respectively. Installed on two vertical plates 5 that are symmetrical along the length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com