Method and device for two-stage mechanical strengthening desulfurization of waste lead plaster

A technology of mechanical strengthening and waste lead paste, applied in the direction of lead carbonate, etc., can solve the problems of waste of resources, high energy consumption in the recycling process, high conversion rate, etc., and achieve the effects of improving desulfurization efficiency, reducing product layer coating, and reducing desulfurization costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

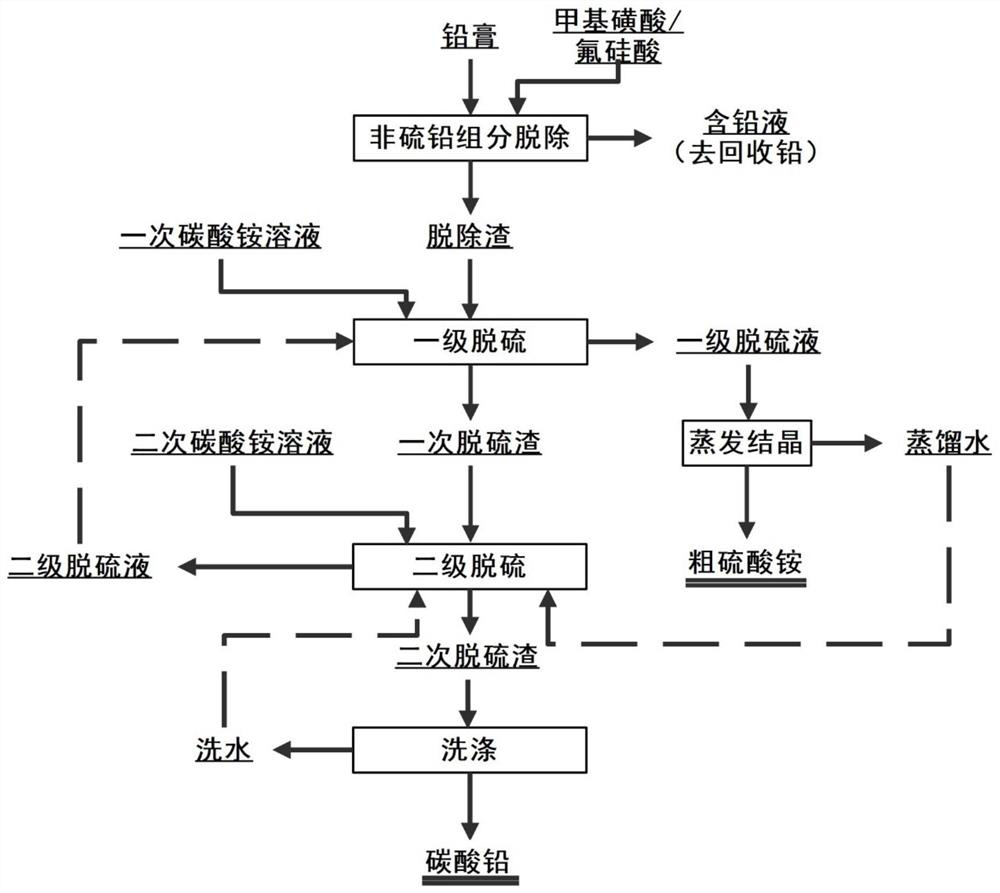

[0026] Follow the steps below to recycle:

[0027] (1) Removal of non-sulfur lead components: waste lead plaster is added in methanesulfonic acid solution to remove non-sulfur lead components such as lead, lead oxide and lead dioxide, wherein the concentration of methanesulfonic acid is 90g / L, the removal temperature is 25°C, the solid-to-liquid ratio is 1.5Kg:10L, and the removal time is 0.5h to obtain the removal slag and lead-containing liquid, and the lead-containing liquid is sent to the lead recovery process;

[0028] (2) Primary desulfurization: Mix the removed slag obtained in step (1) with primary ammonium carbonate solution to perform primary desulfurization, wherein the ammonium carbonate concentration is 530g / L, and the solid-to-liquid ratio is 5Kg:2L, primary desulfurization The gap between the inner gear and the outer gear of the reactor is 10 μm, the rotation speed is 500 rpm, and the desulfurization time is 5 minutes. After the desulfurization is completed, the...

Embodiment 2

[0033] Follow the steps below to recycle:

[0034] (1) Removal of non-sulfur lead components: waste lead plaster is added in methanesulfonic acid solution to remove non-sulfur lead components such as lead, lead oxide and lead dioxide, wherein the concentration of methanesulfonic acid is 150g / L, the removal temperature is 40°C, the solid-to-liquid ratio is 3Kg:10L, and the removal time is 1h, the slag and lead-containing liquid are obtained, and the lead-containing liquid is sent to the lead recovery process;

[0035] (2) Primary desulfurization: Mix the removed slag obtained in step (1) with primary ammonium carbonate solution to perform primary desulfurization, wherein the concentration of ammonium carbonate is 550g / L, and the solid-to-liquid ratio is 3Kg:1L. The gap between the inner gear and the outer gear of the reactor is 15 μm, the rotation speed is 2000 rpm, and the desulfurization time is 20 minutes. After the desulfurization is completed, the solid-liquid separation i...

Embodiment 3

[0040] Follow the steps below to recycle:

[0041] (1) Removal of non-sulfur lead components: Add waste lead paste to the fluosilicic acid solution to remove non-sulfur lead components such as lead, lead oxide and lead dioxide, wherein the concentration of fluosilicic acid is 140g / L, the removal temperature is 25°C, the solid-liquid ratio is 1.5Kg:10L, and the removal time is 1h to obtain the removal slag and lead-containing liquid, and the lead-containing liquid is sent to the lead recovery process;

[0042] (2) Primary desulfurization: Mix the removed slag obtained in step (1) with primary ammonium carbonate solution to perform primary desulfurization, wherein the concentration of ammonium carbonate is 530g / L, and the solid-to-liquid ratio is 3Kg:1L. The gap between the inner gear and the outer gear of the reactor is 15 μm, the rotation speed is 2000 rpm, and the desulfurization time is 20 minutes. After the desulfurization is completed, the solid-liquid separation is carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com