Waterborne wood coating as well as preparation method and use method thereof

A wood coating, water-based technology, applied in the coating and other directions, can solve the problems of restricting the application of water-based wood coatings, and achieve the effects of good flatness, strong leveling performance, and good crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

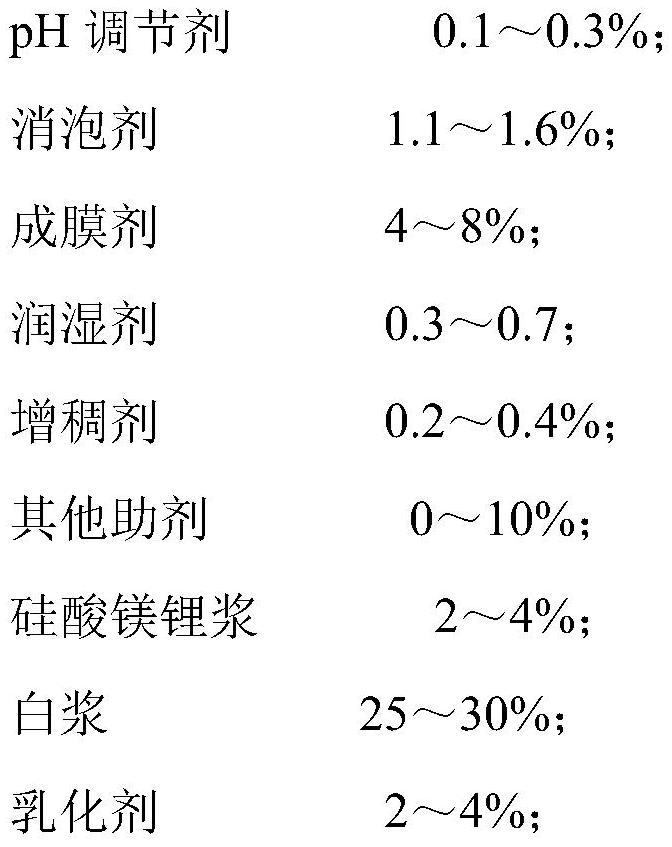

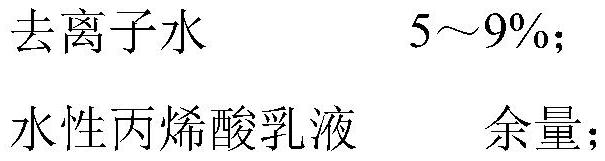

Method used

Image

Examples

Embodiment 1~3

[0053] Embodiments 1-3 are a kind of water-based wood coating, and the specific material ratio is shown in Table 1.

Embodiment 4~8

[0063] Examples 4-8, a water-based wood coating, differ from Example 2 in that the emulsifiers are replaced by EL-80, EL-90, TRITON X-405, TRITON X-100, and Pluronic PE 3100 in equal amounts.

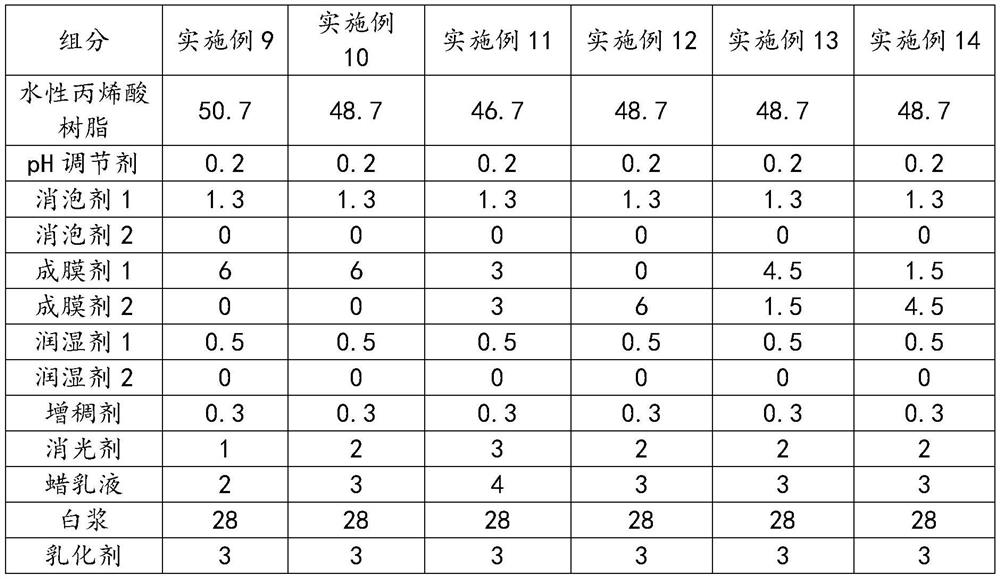

Embodiment 9~14

[0068] Examples 9-14, a water-based wood coating, are different from Example 2 in that the specific components are shown in Table 2.

[0069] Component ratio (%) in table 2, embodiment 9~14

[0070]

[0071]

[0072] Wherein, film forming agent 2 is dipropylene glycol monobutyl ether. Matting agent and wax emulsion are added into the system together with other components in step S3. The matting agent is Degussa OK520, and the wax emulsion is BYK AQUACER 535.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com