Electric motor coach

A technology for electric passenger cars and car bodies, applied in electric vehicles, electric power devices, vehicle energy storage, etc., to achieve the effect of simplifying the internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

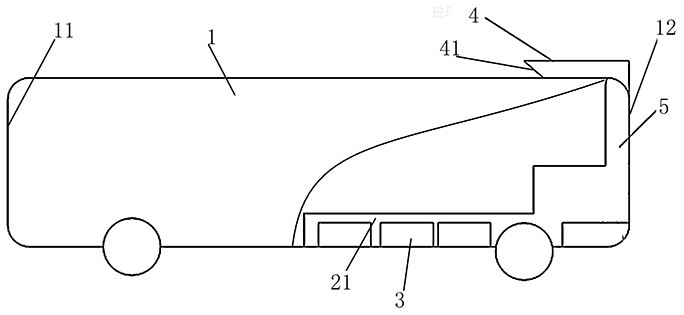

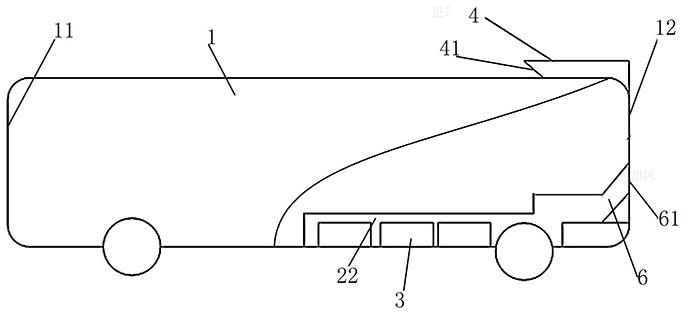

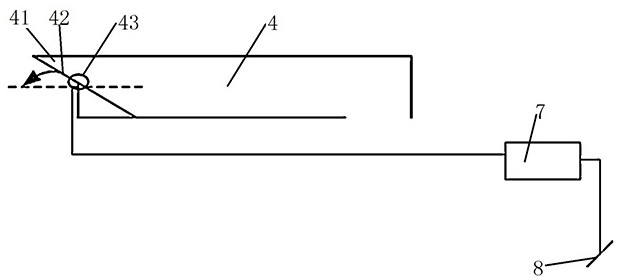

[0042] like Figure 1 to Figure 4 As shown, the electric bus includes a car body 1, the length of which extends along the front and rear directions. The front end of the car body 1 is a front end 11, and the rear end is a rear end 12. The left and right width directions are arranged, that is, the battery compartment 22 on the left side and the battery compartment 21 on the right side, such as image 3 As shown, a battery compartment partition 23 is set between the two battery compartments, but the two battery compartments are connected to each other, and the two battery compartments are arranged near the rear end of the vehicle body 1, and a battery pack 3 is fixed in each battery compartment, and the vehicle body 1 is provided with a heat dissipation channel for the battery compartment, which is used to introduce natural wind to cool the battery compartment.

[0043] In this embodiment, the heat dissipation channels of the battery compartment specifically include the air duc...

specific Embodiment 2

[0052] The difference between it and Embodiment 1 mainly lies in that in Embodiment 1, the air outlet is arranged on the rear side of the vehicle body. In this embodiment, the air outlet can also be arranged on the bottom surface of the vehicle body to form a form of heat dissipation that goes in and out from the top.

specific Embodiment 3

[0054] The main difference between it and Embodiment 1 is that in Embodiment 1, damper motors are respectively provided at the air outlet and the air inlet to control the closing of the corresponding dampers. In this embodiment, the air inlet damper may only be provided at the air inlet, and the air outlet damper may be omitted at the air outlet. At this time, care should be taken to arrange a ventilation grille at the air outlet to form a barrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com