Spring claw forming and drawing equipment for fire hose and use method of spring claw forming and drawing equipment

A technology for drawing equipment and fire hoses, applied in the field of spring claw processing, can solve the problems of manpower and time cost, inability to rapidly process spring claw at multiple stations, and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

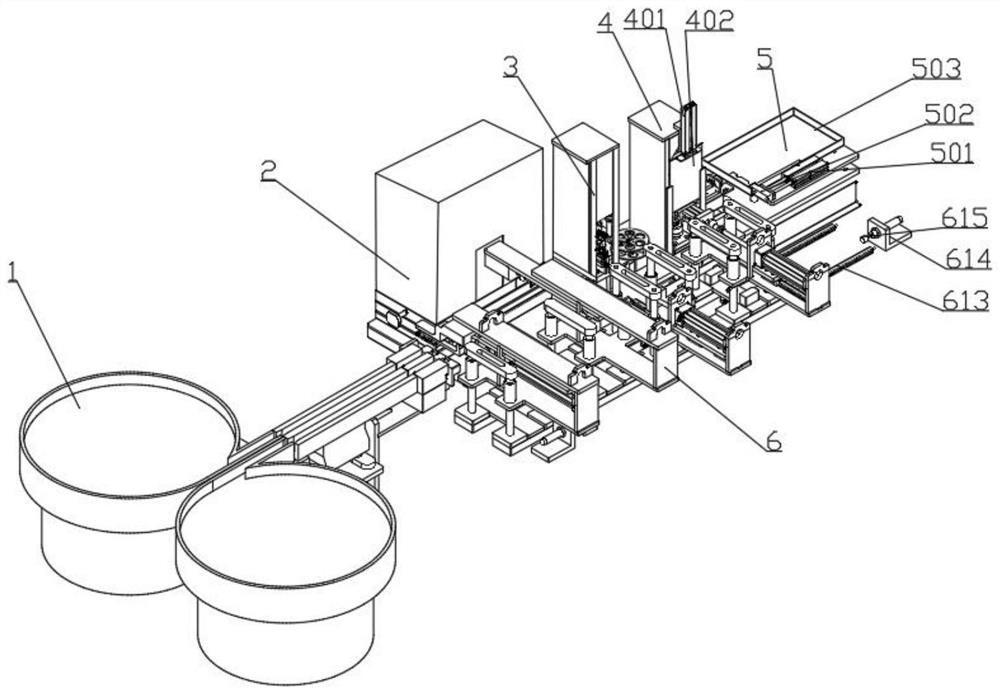

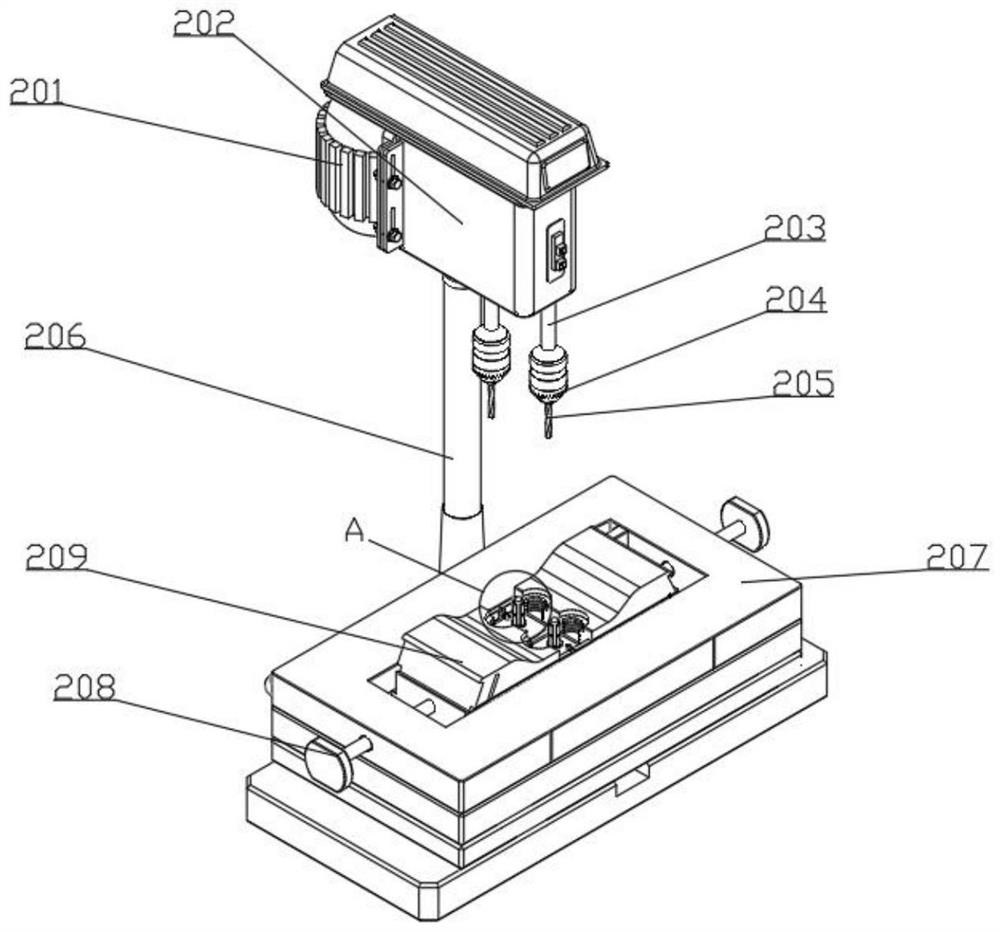

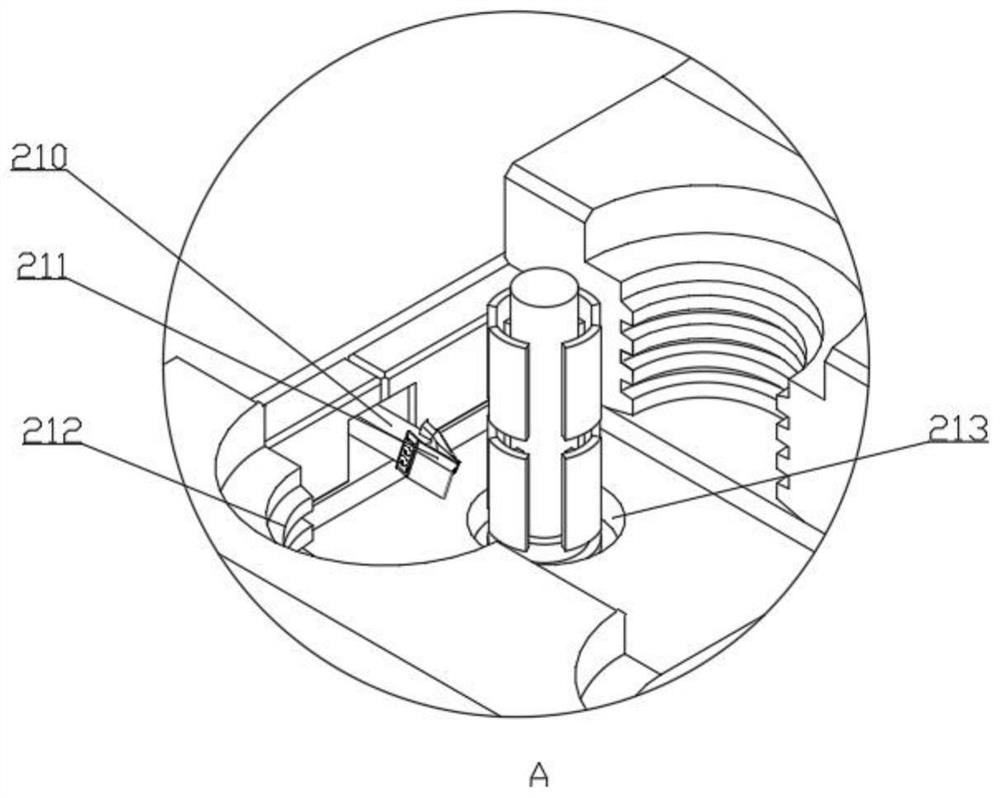

[0048] A spring claw forming and drawing equipment for a fire hose, comprising a blanking part 1, a drilling part 2, a riveting part 3, a dividing part 4, a collecting part 5 and a picking part 6, a blanking part 1, a drilling part 2, The riveting part 3, the dividing part 4, and the collecting part 5 are arranged at intervals on one side of the picking part 6, and the picking part 6 picks up parts and cooperates with the blanking part 1, the drilling part 2, the riveting part 3, the dividing part 4, and the collecting part 5. Line multi-process processing.

[0049] The present invention includes a blanking part 1, a drilling part 2, a riveting part 3, a dividing part 4, a collecting part 5 and a pick-up part 6. The position of the workpiece is adjusted and placed by the blanking part, which is convenient for the pick-up part 6 to quickly pick up the workpiece. Picking, the drilling part 2, the riveting part 3, the dividing part 4, and the collecting part 5 are arranged at int...

Embodiment 2

[0061] A spring claw forming and drawing equipment for a fire hose, comprising a blanking part 1, a drilling part 2, a riveting part 3, a dividing part 4, a collecting part 5 and a picking part 6, a blanking part 1, a drilling part 2, The riveting part 3, the dividing part 4, and the collecting part 5 are arranged at intervals on one side of the picking part 6, and the picking part 6 picks up parts and cooperates with the blanking part 1, the drilling part 2, the riveting part 3, the dividing part 4, and the collecting part 5. Line multi-process processing.

[0062]The present invention includes a blanking part 1, a drilling part 2, a riveting part 3, a dividing part 4, a collecting part 5 and a pick-up part 6. The position of the workpiece is adjusted and placed by the blanking part, which is convenient for the pick-up part 6 to quickly pick up the workpiece. Picking, the drilling part 2, the riveting part 3, the dividing part 4, and the collecting part 5 are arranged at inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com