Large-board square cabin everywhere installation structural member and installation method thereof

A technology for installing structures and adhesives, applied in building construction, building material processing, construction, etc., can solve the problems of reduced wall strength, high risk of delamination, impact, etc., to improve tensile capacity and expand the bottom. Simple structure and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

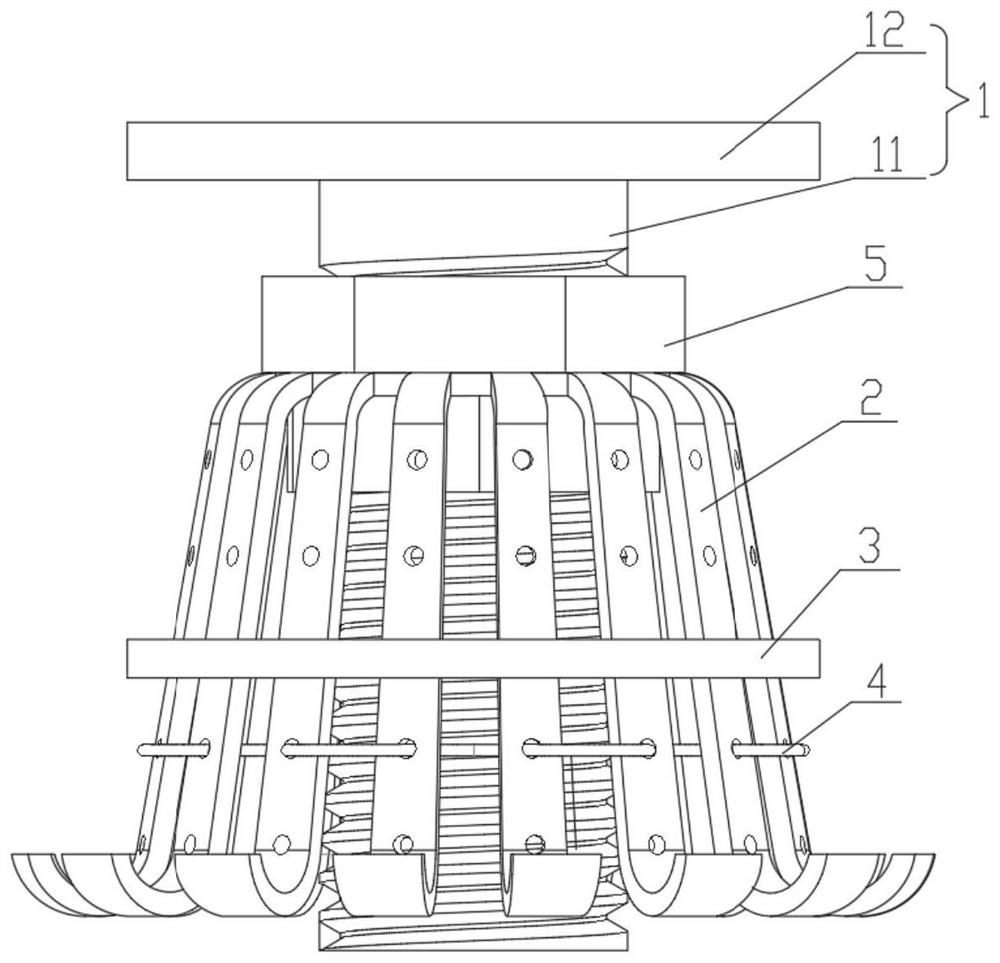

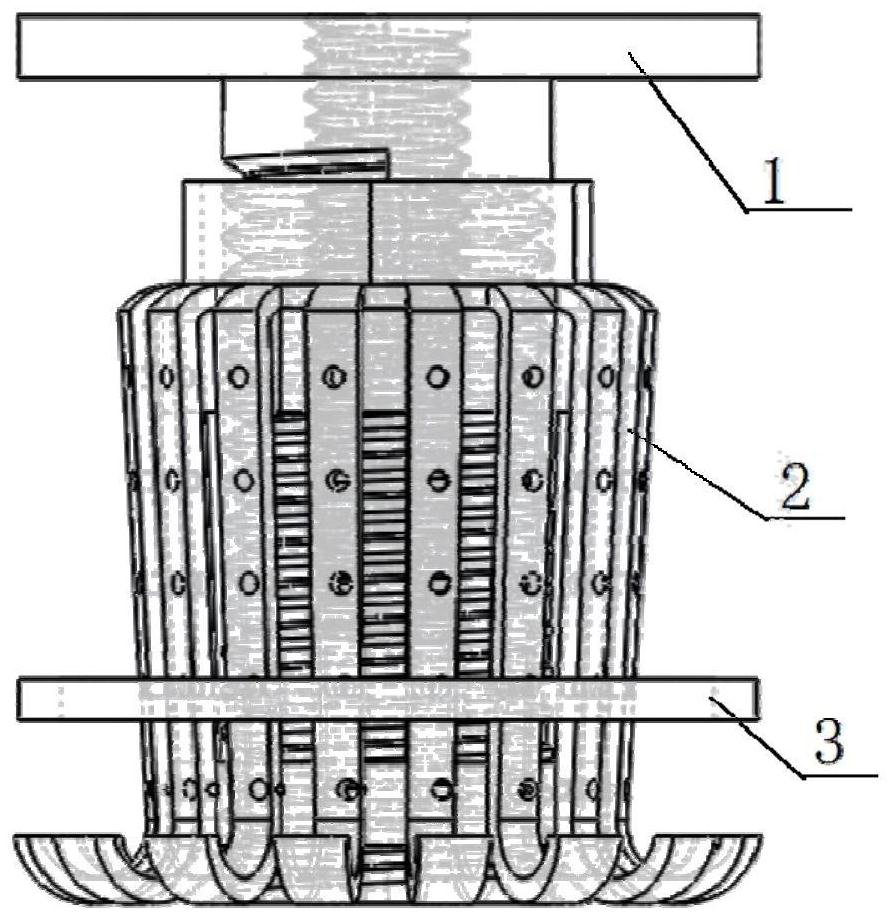

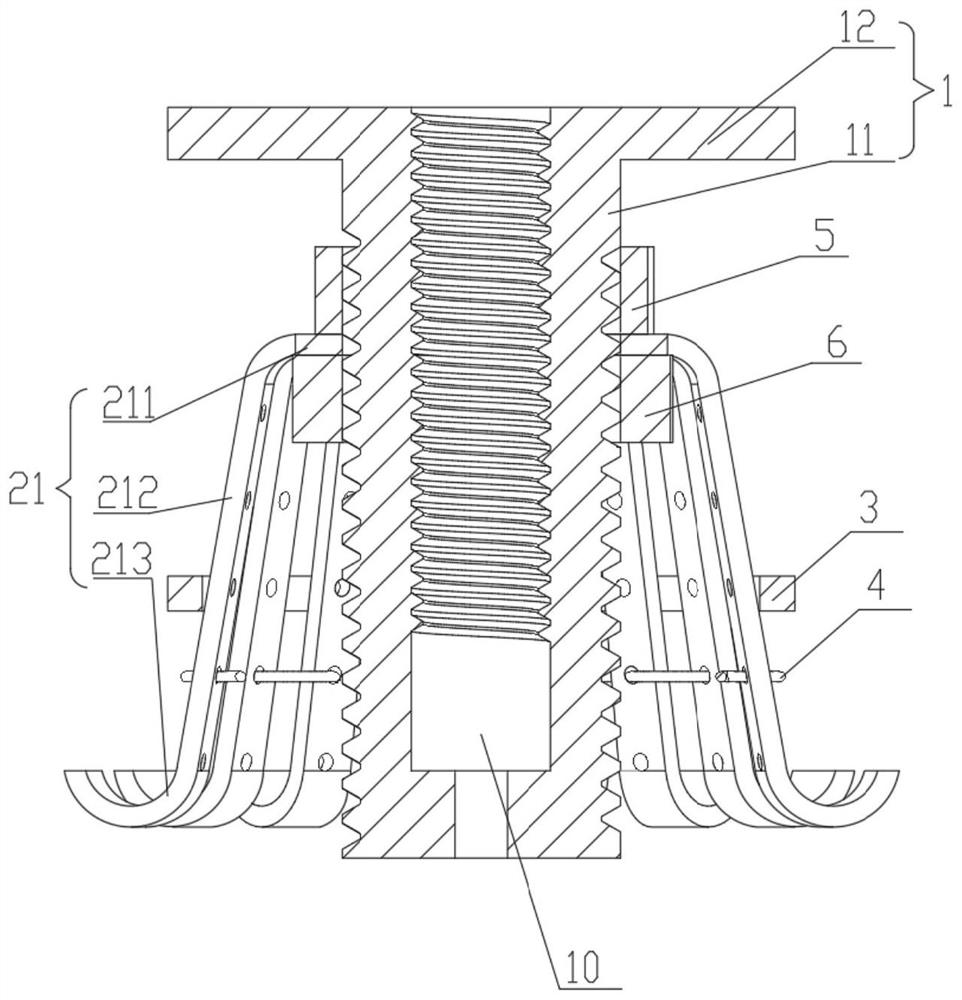

[0028] Below in conjunction with the accompanying drawings, the large slab shelter structure provided by the present invention and its installation method will be explained in detail.

[0029] Such as figure 1 As shown, this embodiment specifically discloses a structural member installed anywhere in a large slab shelter, including a base 1, an elastic jaw disc 2 and a shrink ring 3, and an axial glue injection hole 10 is provided inside the base 1 for use in For injecting the adhesive; the inner wall of the glue injection hole 10 is provided with threads, which are used to connect with the fixing bolts of the fixing equipment. In this example, if image 3 As shown, the thread is arranged on the upper half of the glue injection hole 10, and the inner diameter of the tail of the glue injection hole 10 can be shrunk to be smaller than the inner diameter of the upper part.

[0030] Such as figure 1 As shown, the elastic jaw disc 2 is coaxially sleeved and fixed on the outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com