Steel rail multidirectional straightening hydraulic machine and complete device

A complete set of device, hydraulic press technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of cumbersome process, waste of manpower, material resources, low work efficiency, etc., to improve production efficiency, wide application range, reduce labor and the effect of hoisting times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

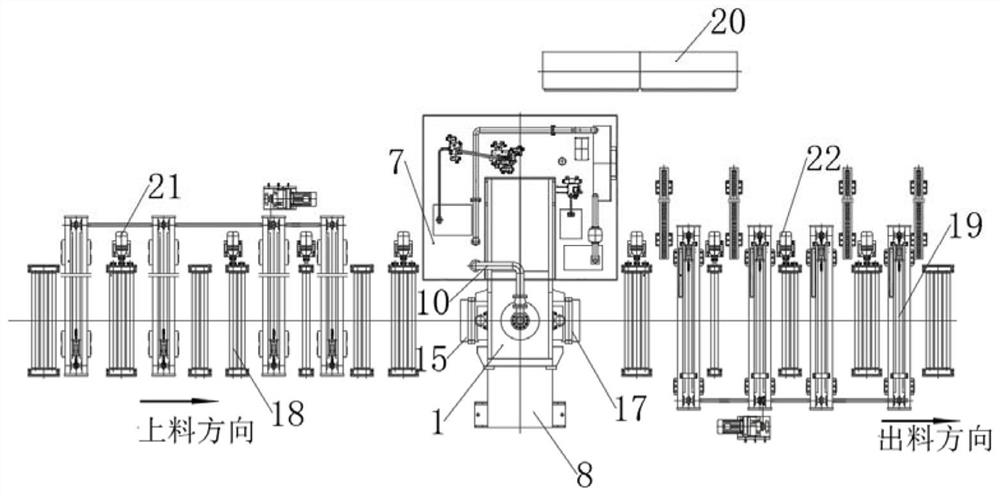

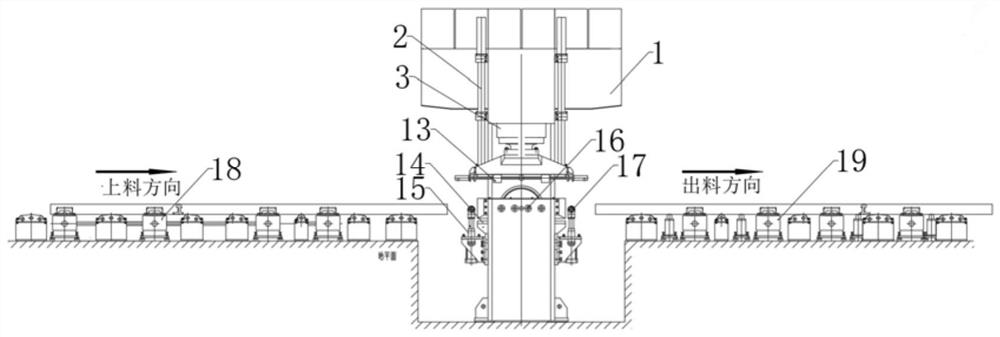

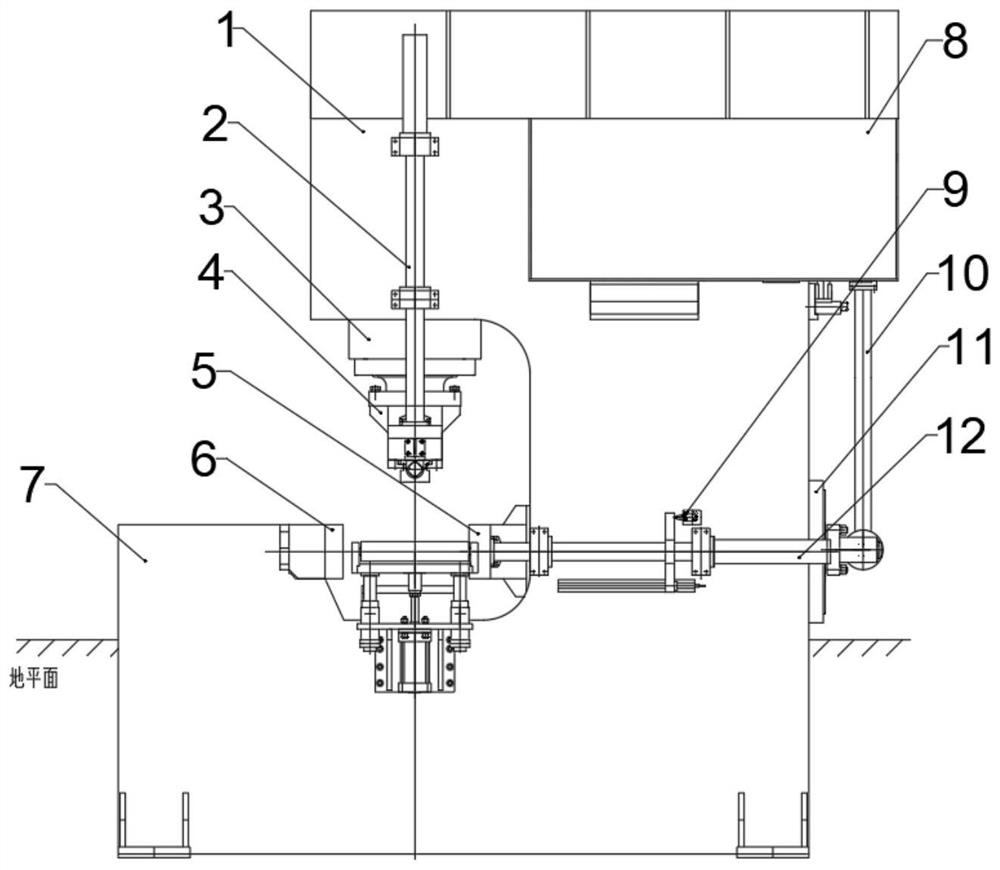

[0028] see Figure 1-5 , a rail multi-directional straightening hydraulic press and a complete set of equipment, including a main machine, a feeding system 18 and a feeding system 19 are respectively arranged on both sides of the main machine, and a pushing mechanism 16 is arranged inside the main machine, and the pushing mechanism 16 is arranged on the feeding system 18 and the unloading system 19, the loading system 18 is driven by the loading drive motor 21, the unloading system 19 is driven by the unloading drive motor 22, the host, the loading drive motor 21, the unloading drive motor 22 and the pushing mechanism 16 are all controlled by the electrical system 20; the host computer includes a vertical fuselage 1 and a horizontal fuselage 7, the vertical fuselage 1 is fixedly connected to one side of the upper end of the horizontal fuselage 7, and the joint of the vertical fuselage 1 and the horizontal fuselage 7 is provided with a school In the straightening operation area...

Embodiment 2

[0033] What is different based on embodiment 1 is:

[0034] Such as Figure 5-7 As shown, the lower end of the slider 4 in the vertical direction is provided with an alignment fixing mechanism 13, and the alignment fixing mechanism 13 includes an upper fixing piece and a lower fixing piece, the upper fixing piece is arranged below the vertical slider 4, and the lower fixing piece is arranged in the horizontal direction On the workbench 6, the lower fixing part is arranged on the side that deviates from the vertical projection of the upper fixing part, and the upper fixing part includes two sets of straightening indenters 13-6, and the straightening indenters 13-6 are threadedly connected to the positioning screw rod 13-8 On, the outer end of the positioning screw 13-8 is fixedly connected with the output end of the servo power source 2 13-5;

[0035] Servo power source 2 13-5 is fixedly connected to the lower end of the vertical slider 4, the upper side of the straightening p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com