Apparatus for catalytically reforming hydrocarbons with flow distributors and method for reforming hydrocarbons

A flow distributor and catalyst technology, which is applied in the field of productivity devices, can solve the problems of low utilization, uneven distribution of process gas, flow shock, etc., and achieve the effect of reducing turbulent flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

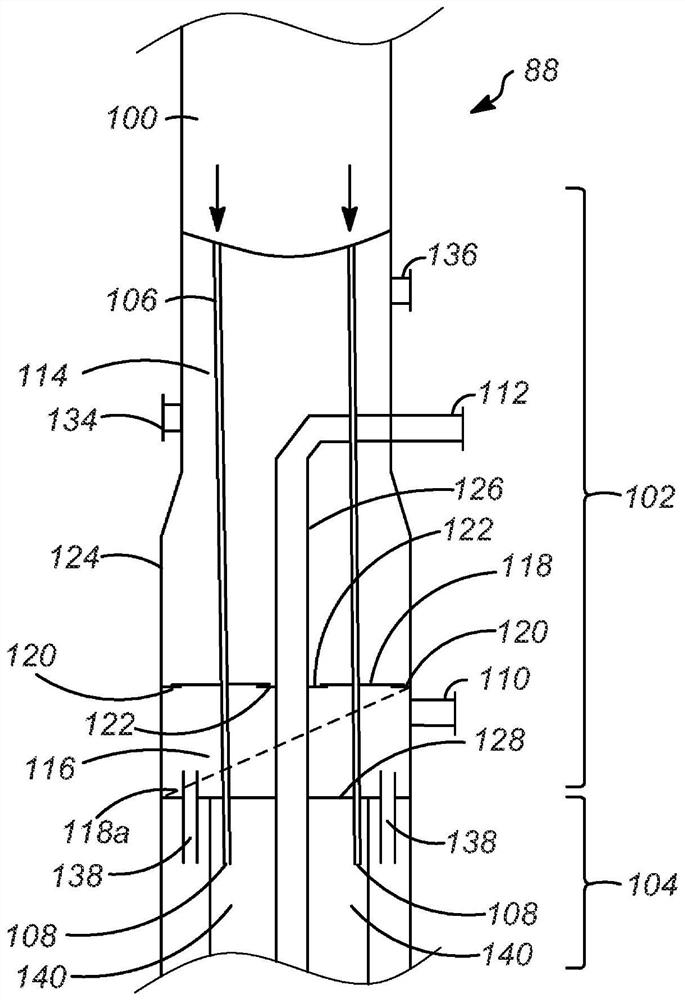

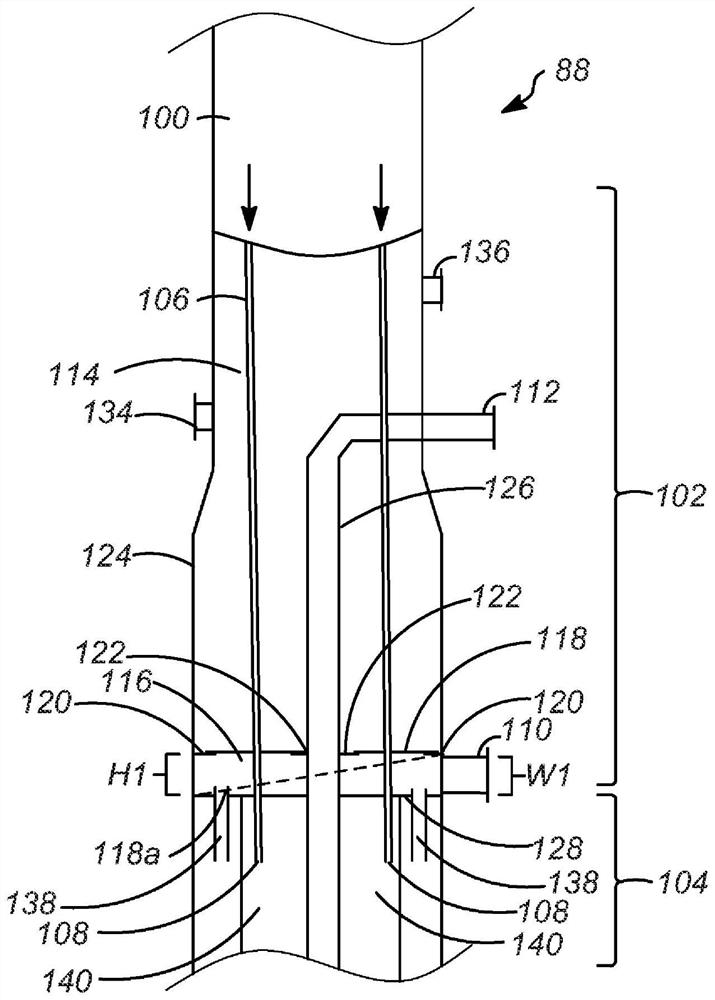

[0019] As described above, the reactors and processes for reorganizing hydrocarbons have been invented, in which the outlet nozzles are located above the inlet nozzle. In addition, a flow distributor can be provided to divide the non-reactive zone into two sections. According to aspects of the invention, the flow distribution from the non-reactive zone to the reaction zone can be improved by 2-4%. Considering these general principles, one or more embodiments of the present invention will be described below in understanding the following description.

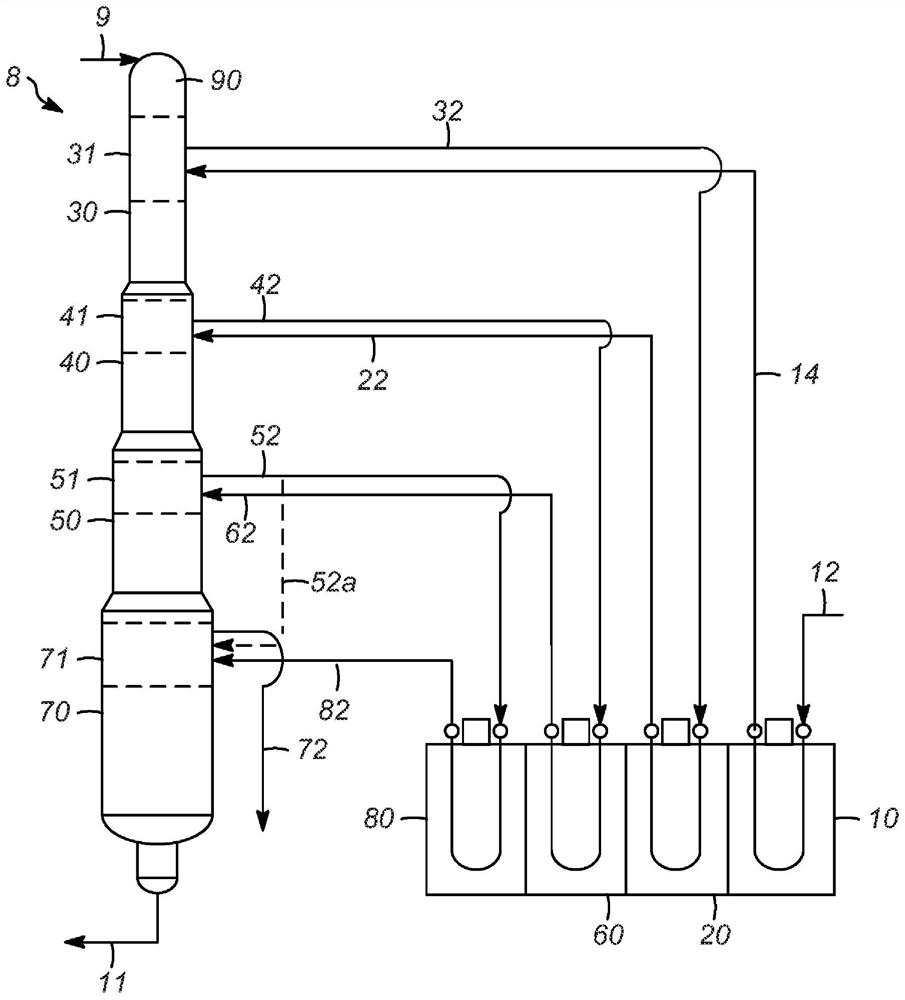

[0020] refer to figure 1 The present invention relates to a reforming reactor 8 for a hydrocarbon feed stream 12. The hydrocarbon feed stream 12 typically comprises a boiling point of a cycloalkane and a alkane hydrocarbon in a gasoline fraction. Preferred feed streams 12 include direct rhythmic oil, thermal cracking or catalytic cracking stone oil, partially reforming naphtha, from the extracted liquid from an aromatic compound. Typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com