Cylindrical laminated busbar structure

A laminated busbar, cylindrical technology, applied in the connection/disconnection of connecting components, electrical components, connections, etc., can solve the problems of low vibration reliability of high and low voltage wiring harnesses, limited layout space, etc., and achieve layout space. Unrestricted, reliable, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

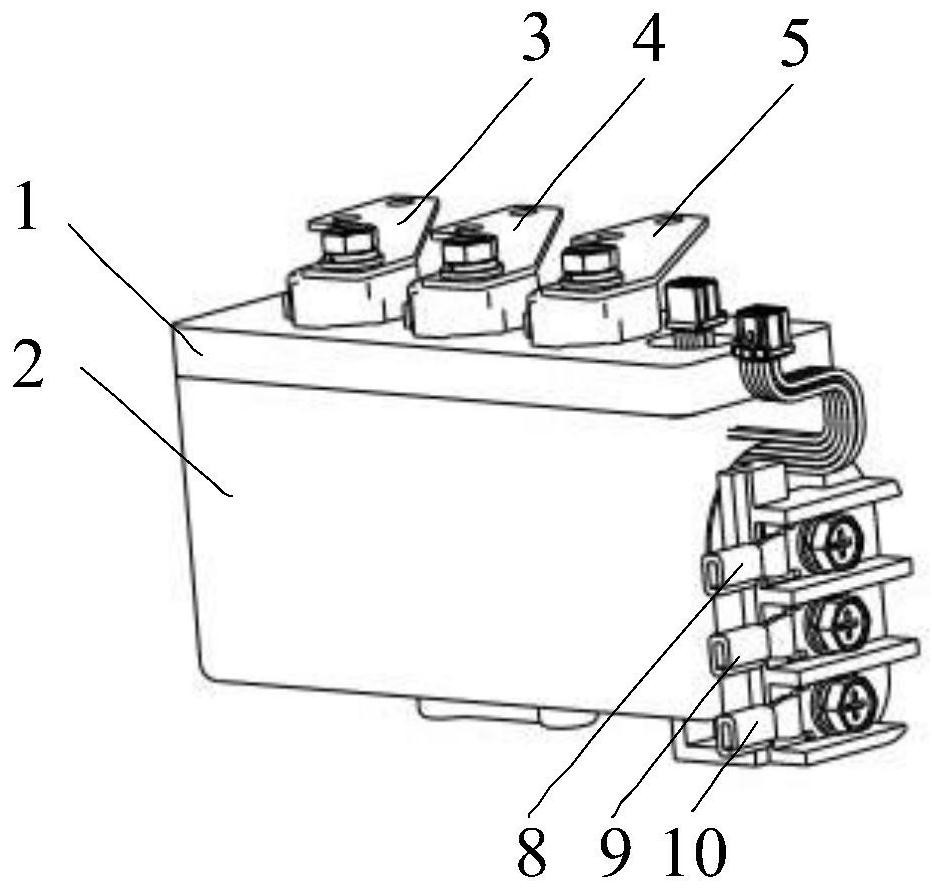

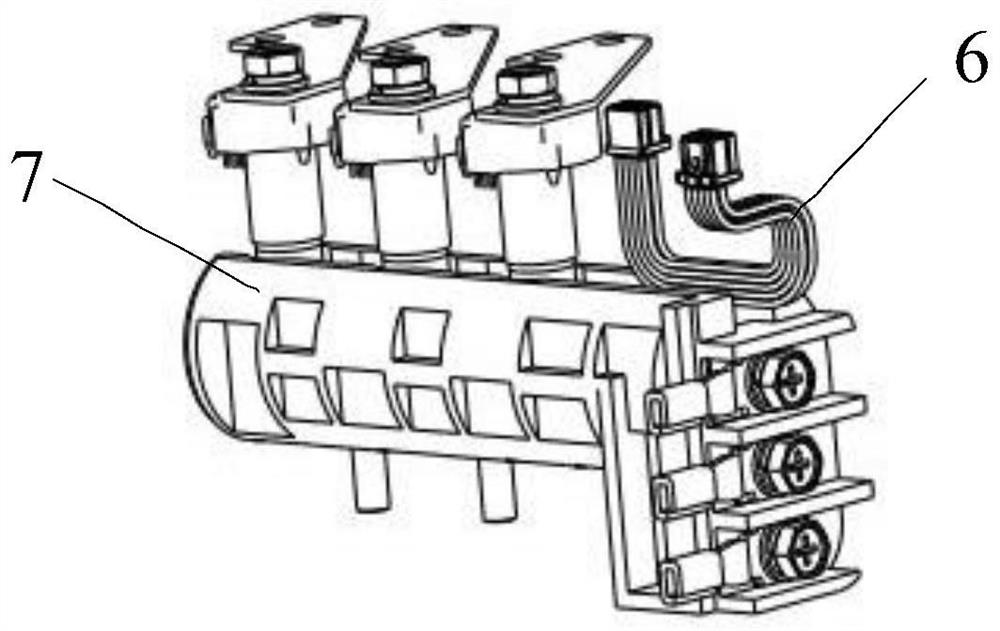

[0027] Such as Figure 1 to Figure 6 Shown: a cylindrical laminated busbar structure, including the shell, input high-voltage terminal group, output high-voltage terminal group, low-voltage wire harness 6, copper bar group and laminated busbar seat 7; shielding is provided between the above structures layer or insulating material; the input high-voltage terminal group is connected to the laminated busbar seat 7, the copper bar group is arranged in the laminated busbar seat 7, and the two ends of the copper bar group are respectively connected The input high-voltage terminal group and the output high-voltage terminal group, the low-voltage wire harness 6 is arranged on the laminated busbar seat 7, and the laminated busbar seat 7 is arranged in the shell; it also includes wiring The input high-voltage terminal group is connected to the laminated busbar seat 7 through the terminal.

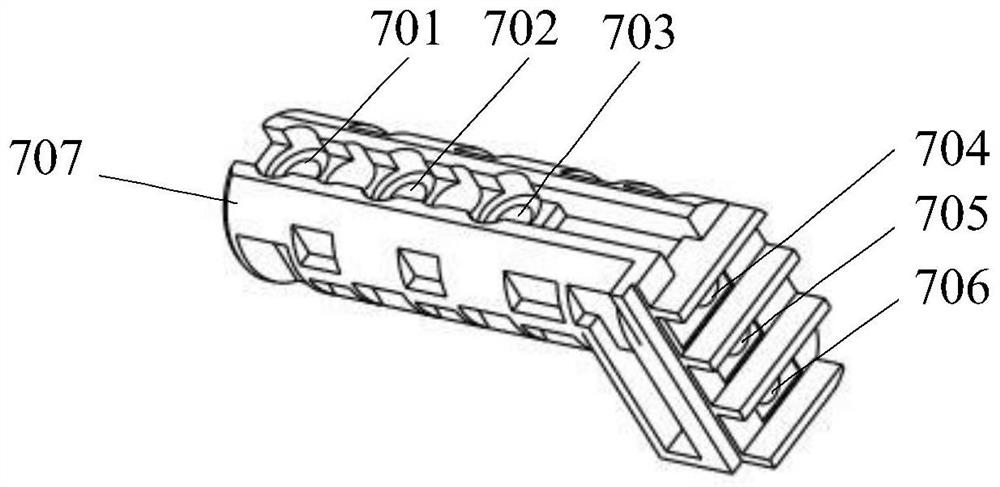

[0028] The upper part of the laminated busbar seat 7 is an outer rotary surface 707 structure, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com