A liquid metal-based hot-melt drill bit for vertical drilling of polar grain snow layers

A liquid metal and vertical drilling technology, which is applied in directional drilling, earthwork drilling, drilling equipment, etc., can solve the problems of uneven heating of the drill head, poor uniformity, and limitation of the length of the drilling tool, so as to reduce the probability of drill sticking and simplify the ground surface Equipment and the effect of saving drilling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to illustrate the present invention more clearly, the present invention will be further described below with reference to the preferred embodiments and accompanying drawings. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention. Unless otherwise defined, technical or scientific terms used herein should have the ordinary meaning as understood by one of ordinary skill in the art to which this invention belongs.

[0022] Well-known methods, procedures, procedures, components and circuits have not been described in detail in order to avoid obscuring the essence of the present invention.

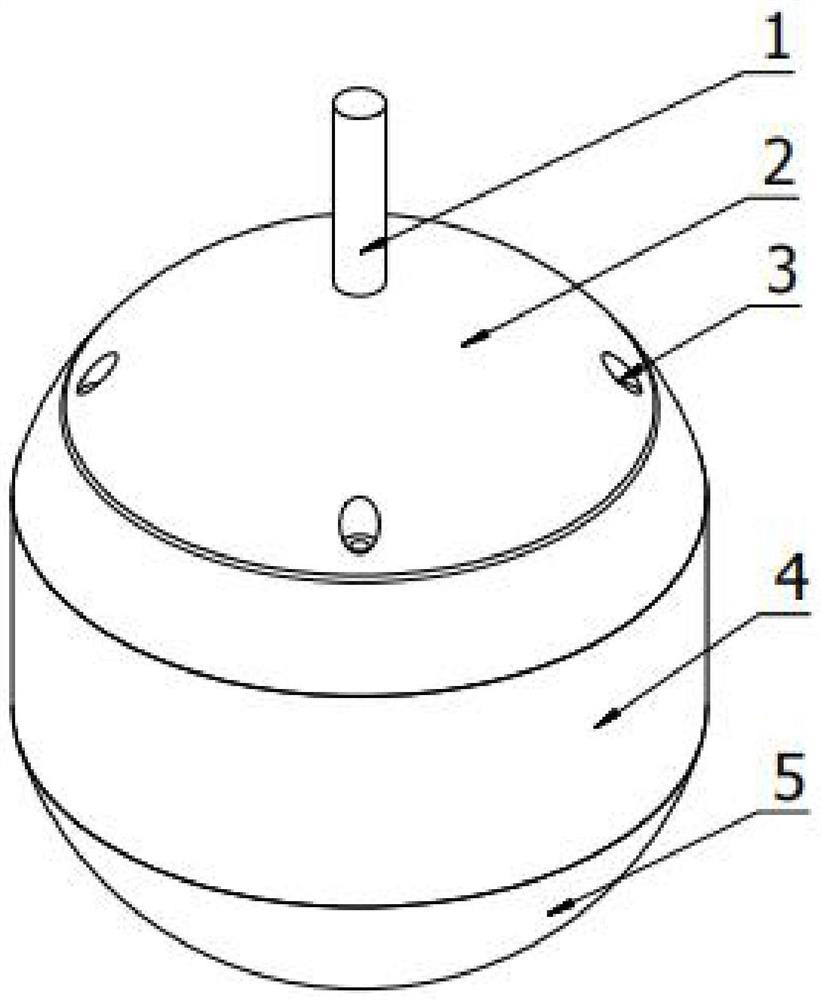

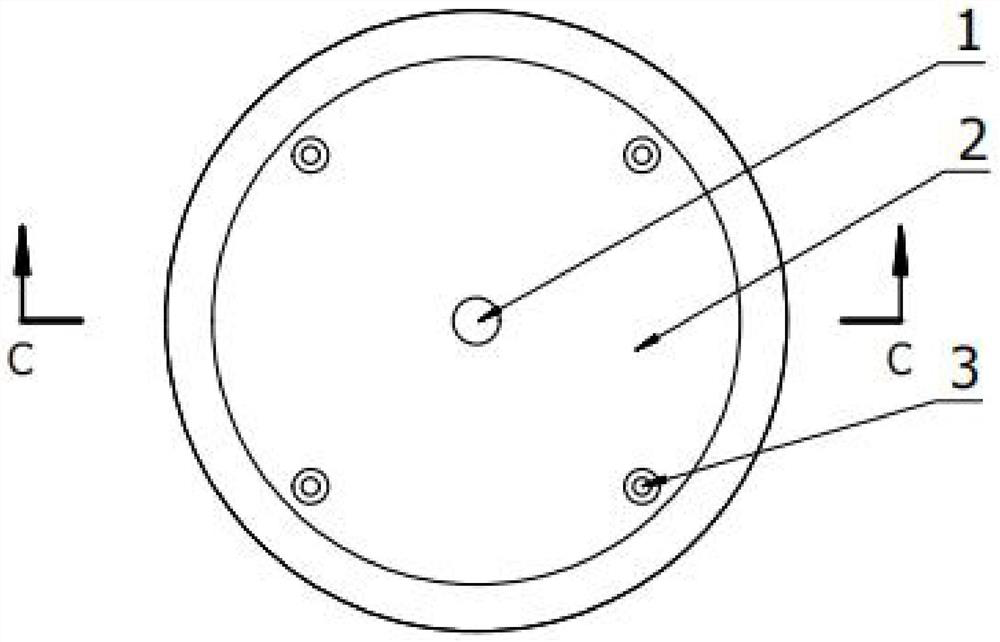

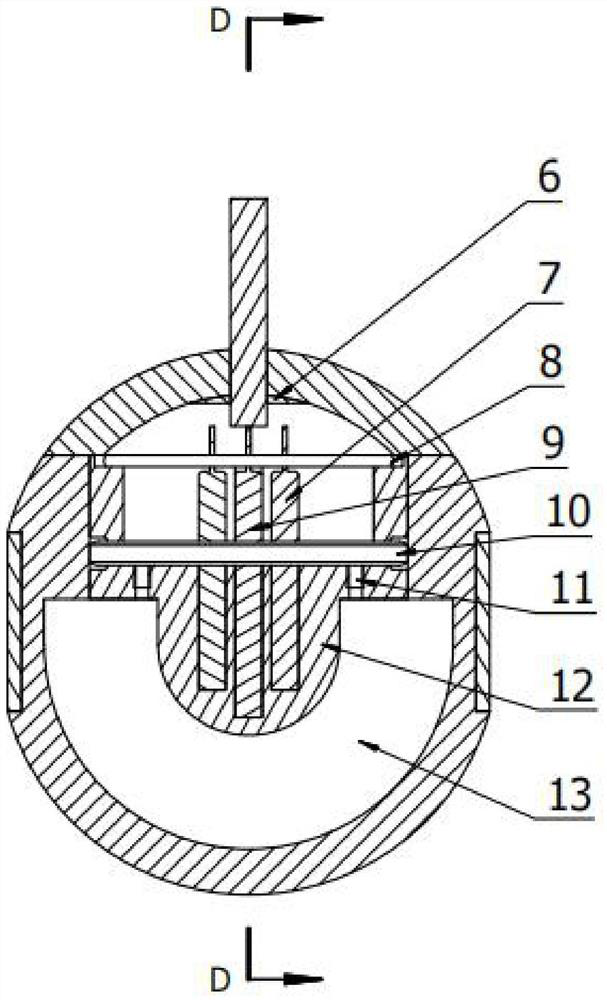

[0023] like figure 1 , figure 2 , image 3 and Figure 4 As shown in the figure, a liquid metal-based polar grain snow layer vertical drilling hot-melting drill bit includes a power supply cable 1, an upper cover 2, an insulating ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com