Sludge soil layer mixing pile reinforcing structure and construction method

A technology for strengthening structures and mixing piles, applied in the field of mixing piles, can solve the problems of low connection strength and achieve the effect of improving connection strength and verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

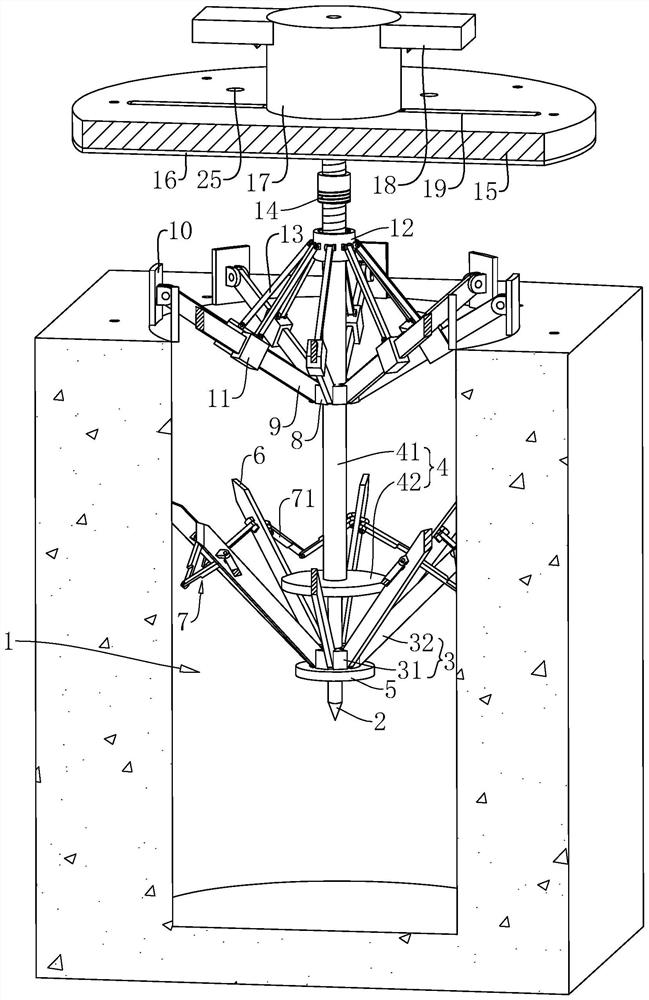

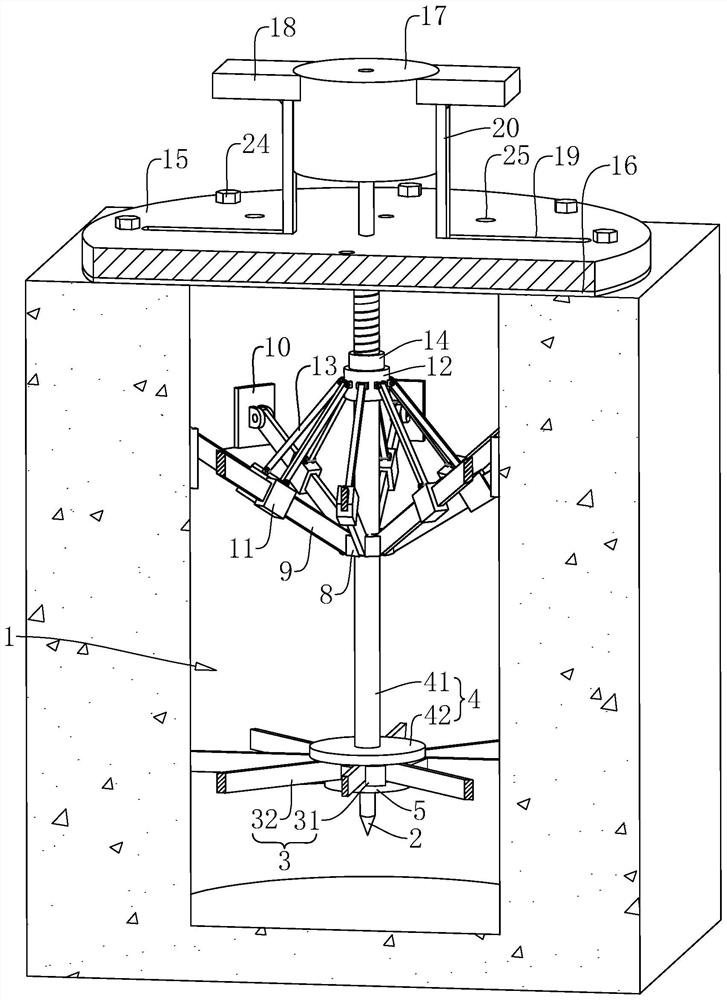

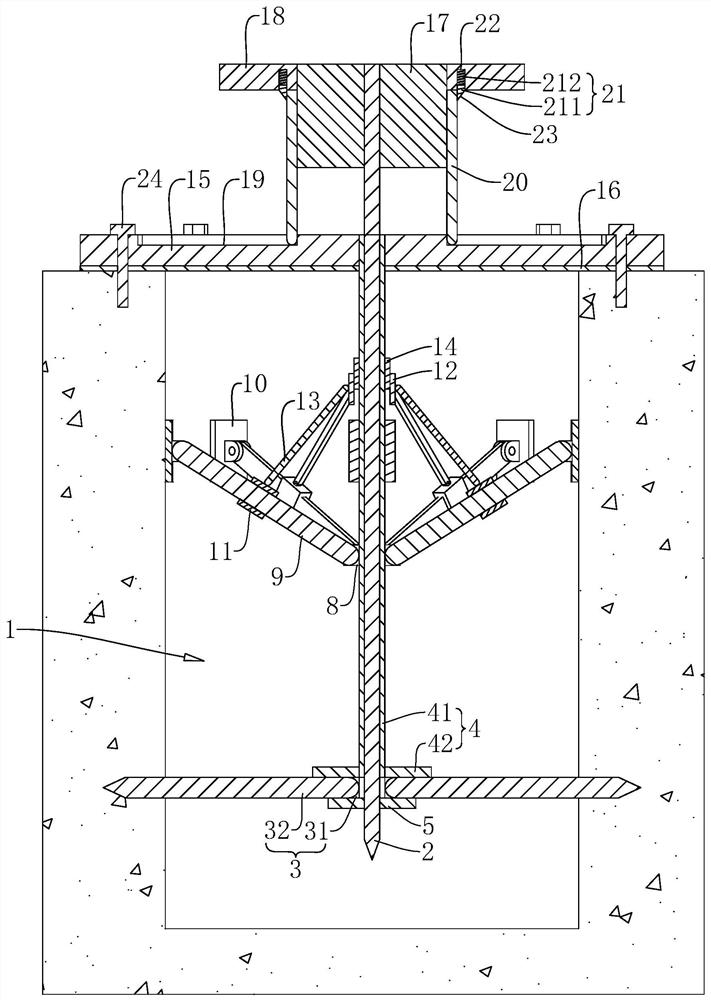

[0040] The following is attached Figure 1-3 The application is described in further detail.

[0041] The embodiment of the application discloses a reinforcement structure of a stirring pile in a muddy soil layer.

[0042] refer to figure 1 and figure 2 A reinforcement structure for mixing piles in silty soil layers includes a mixing pile body 1 and reinforcing ribs 2, the mixing pile body 1 is a cylindrical pile body, and the reinforcing ribs 2 are provided for improving the distance between the mixing pile body 1 and the silty soil layer. Reinforcement mechanism 3 with high connection strength, reinforcement mechanism 3 is made up of connection core 31 and several outer ribs 32 uniformly hinged on the side of connection core 31, connection core 31 is coaxially sleeved on the bottom of reinforcement rib 2 and connected with reinforcement rib 2 Welding, the length of each externally expanded rib 32 is equal, and the length of the externally expanded rib 32 is greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com