Material collecting device and image-text cutting machine

A technology of receiving device and cutting area, which is applied in the cutting of textile materials, textile and papermaking, metal processing, etc., which can solve the problems of fabric wrinkles and low efficiency, and achieve the effects of avoiding wrinkles, improving reliability, and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

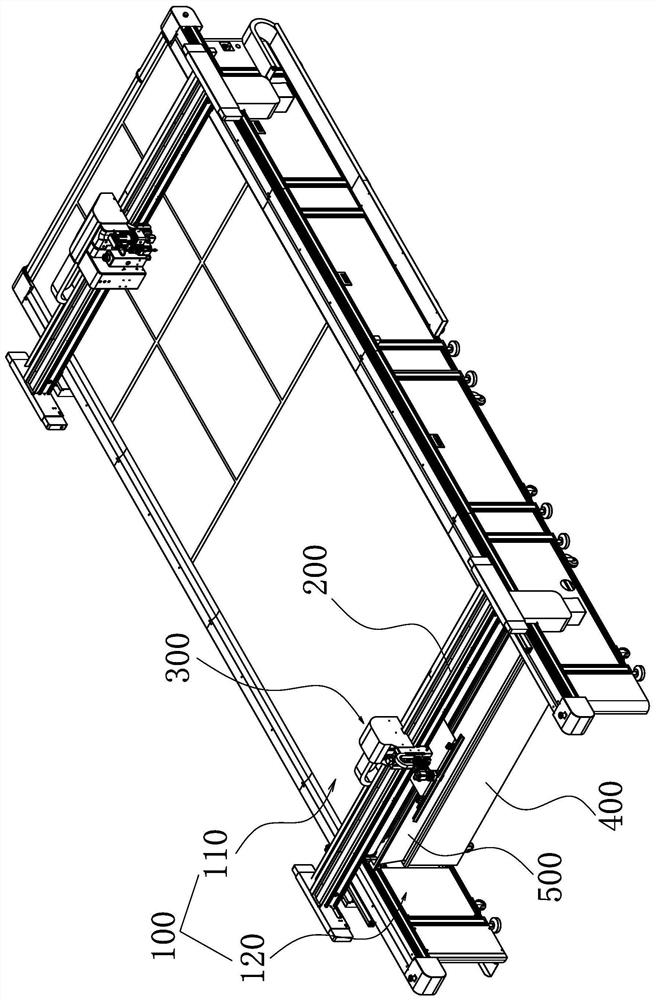

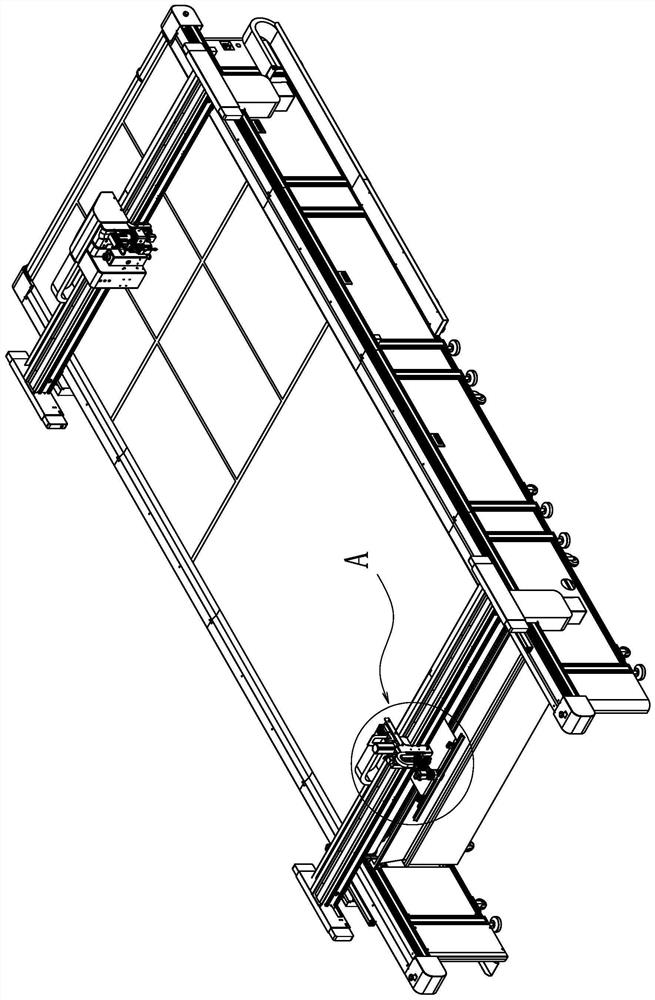

[0043] Such as Figure 1 to Figure 10 ,as well as Figure 14 As shown, a kind of receiving device provided by the present invention includes:

[0044] The frame 100 is sequentially provided with a cutting area 110 and a receiving area 120 along the conveying direction of the cloth;

[0045] The gantry 200 spans both sides of the frame 100 and is connected to both sides of the frame 100, wherein the gantry 200 can slide along the length direction of the frame 100;

[0046] The receiving assembly 300 is installed on the gantry 200, and the cut cloth in the cutting area 110 is transferred to the receiving area 120 through the receiving assembly 300, wherein the receiving assembly 300 includes a driving structure 310, and the driving structure 310 includes a drive motor 311, the output end of the drive motor 311 is connected to a reducer 312, wherein, the output end of the reducer 312 is connected to a bidirectional screw rod 313, and two grabbing parts are screwed on the bidire...

Embodiment 2

[0069] Such as Figure 1 to Figure 14 As shown, the difference between this embodiment and the first embodiment is that the two grasping parts 314 in this embodiment are not set in linkage, and two receiving assemblies 300 are arranged on the gantry 200, In the receiving assembly 300 at this time, the driving structure 310 and the rotating structure 340 can be omitted, and the grasping part 314 is directly connected to the knife seat connecting plate 355 of the lifting structure 350 . However, if the two gripping parts 314 are arranged separately, the flexibility is better.

[0070] It should be noted that, in the present invention, descriptions involving "first", "second", "one" and so on are only for descriptive purposes, and should not be understood as indicating or implying their relative importance or implicitly indicating The number of technical characteristics. Thus, the features defined as "first" and "second" may explicitly or implicitly include at least one of thes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com