Multi-station cloth edge folding device for clothing processing

A multi-station fabric and hemming device technology, applied in the field of apparel processing equipment, can solve the problems of reduced pressure, manual rewinding, and fabric lengthening, etc. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

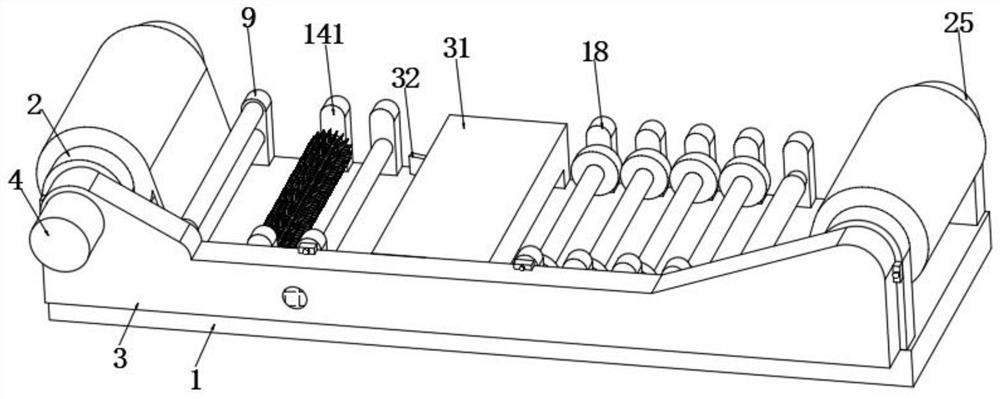

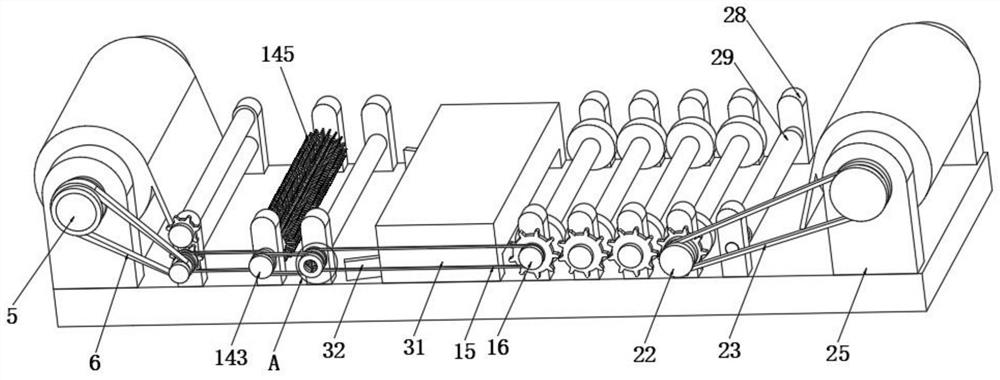

[0039] see Figure 1-9 As shown, the present invention is a multi-station fabric hemming device for clothing processing, including a workbench 1, a fabric rack 2 is arranged on one side of the upper surface of the workbench 1, and a protective cover 3 is fixedly connected to the front surface of the fabric rack 2 At the same time, the inside of the cloth frame 2 is provided with the same anti-reverse mechanism 27 to avoid the rotation of the cloth roll, and the cloth roll wheel is arranged on the cloth frame 2 to facilitate the installation of the cloth roll and facilitate the transportation of the cloth roll. The inside of the rack 2 is provided with the same anti-reversal mechanism 27 in order to avoid the cloth roll pulling the cloth to recover after cutting the cloth, so that the cloth needs to be installed. The side of the protective cover 3 away from the cloth rack 2 is fixedly connected with a drive motor 4 to drive The motor 4 is used as the driving source for setting,...

Embodiment 2

[0044] like Figure 4 To such as Image 6 As shown, the other end of the drive belt two 13 is plugged with a carding mechanism 14, the carding mechanism 14 includes a fixed plate one 141, and a cylindrical runner 142 is rotationally connected between the two fixed plates one 141, and the outer socket of the cylindrical runner 142 Carding plate 145 is arranged, and the front end of cylindrical runner 142 is fixedly connected with transmission roller one 143, and transmission roller one 143 cooperates with transmission belt two 13, drives transmission belt two 13 to move along with belt double wheel 7, and transmission belt two 13 drives transmission The roller one 143 rotates on the fixed plate one 141, so that the carding plate 145 on the outside of the cylindrical runner 142 is driven by the transmission roller one 143 to rotate, so that the carding plate 145 combs the cloth passing below, and simultaneously the transmission roller one 143 The belt chain 144 drives the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com