Pneumatic spray gun

A spray gun and main body technology, applied in the field of pneumatic spray guns, can solve the problems of no constant spraying distance, no automatic feeding function, etc., and achieve the effects of increasing spraying operation efficiency, saving labor consumption, and avoiding uneven spraying thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

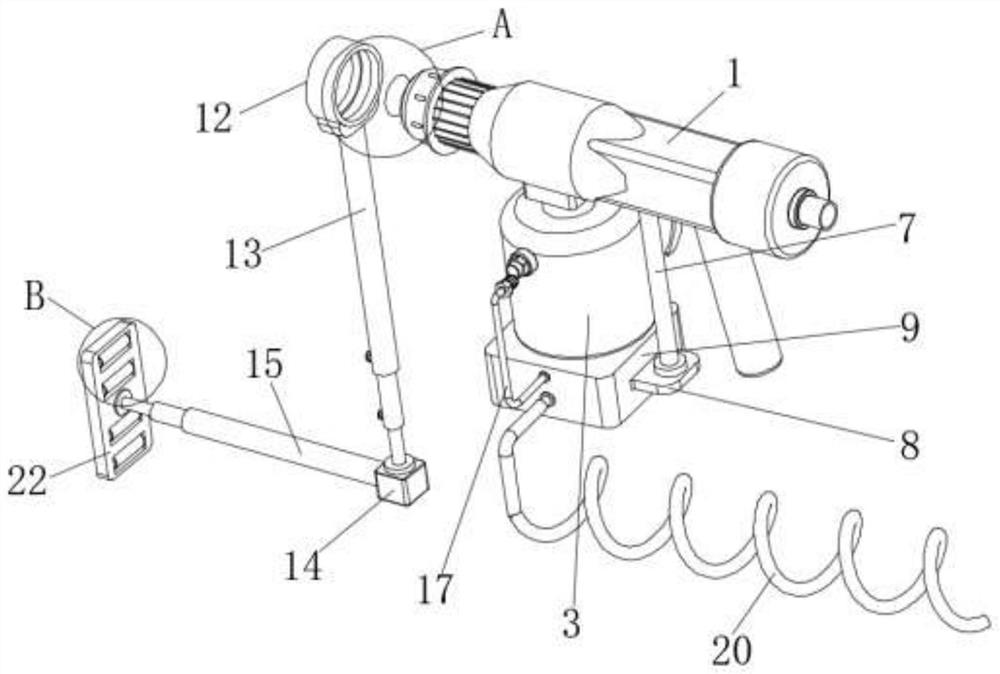

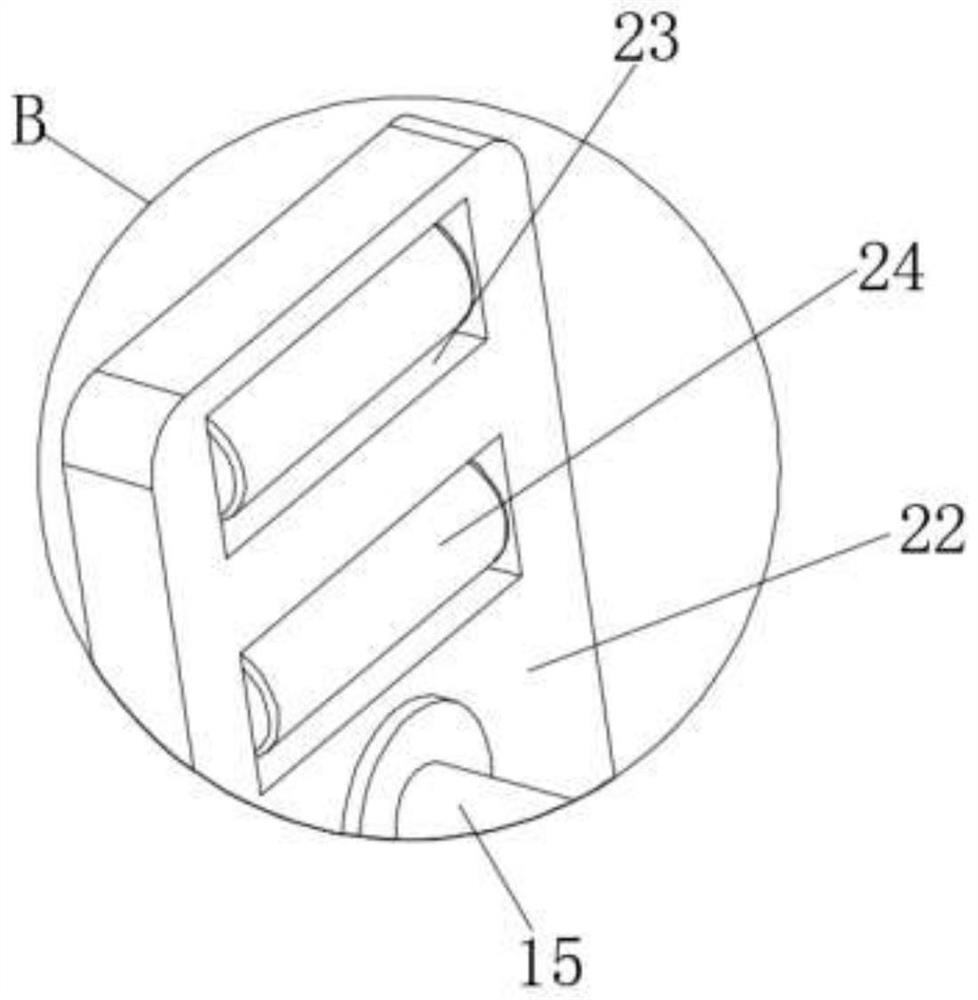

[0028] see Figure 1-6 , the present invention provides the following technical solutions: a pneumatic spray gun, comprising a spray gun main body 1 and a fixed frame 12, one side of the outer surface of the spray gun main body 1 is provided with a feeding pipe 2, and one side of the feeding pipe 2 is provided with a storage tank 3 , the end of the feeding pipe 2 away from the spray gun main body 1 is located inside the storage tank 3, the inner wall of the storage tank 3 is provided with a liquid level sensor 4, and a liquid inlet conduit 5 is arranged above the liquid level sensor 4, and the liquid inlet conduit 5 One end located outside the storage tank 3 is fixedly installed with a quick-plug female connector 6, one side of the feeding pipe 2 is fixedly connected with a fixed rod 7, and the other end of the fixed rod 7 is fixedly connected with a fixed plate 8 through a bearing, and the fixed plate 8 One side of the pipe is fixedly connected with a placement box 9, the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com