Assembled refrigeration vortex tube

A vortex tube and assembled technology, which is applied in the field of assembled refrigeration vortex tubes, can solve the problems of poor separation of hot and cold airflows in vortex tubes, and achieve the effects of facilitating flow separation, improving refrigeration efficiency, and stabilizing airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

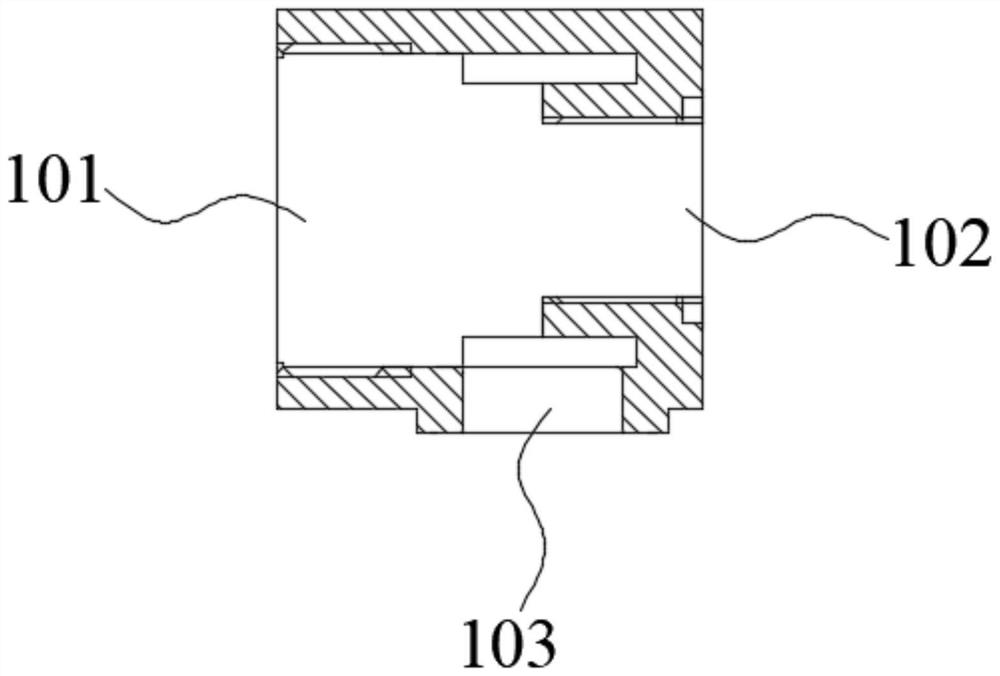

[0040] see Figure 1~6 The assembled refrigeration vortex tube in the preferred embodiment of the present invention includes a vortex chamber 1, in which a first flow channel 101, a second flow channel 102 and a third flow channel 103 are opened, and the three flow channels communicate with each other, and The first flow channel 101 and the second flow channel 102 are coaxially arranged; wherein, the first flow channel 101 is provided with a cold end output pipe 2 for cold flow output, the second flow channel 102 is provided with a spinner 3, and the third flow channel 102 is provided with a spinner 3. Road 103 is provided with an inlet joint 5, and the end of the swirler 3 away from the cold-end output pipe 2 is also provided with a hot-end output pipe 4 for heat flow output; the swirler 3 includes a swirl ring 301, and the swirl ring 301 There is an annular gap between the inner wall of the second channel 102, and the outer circumference of the swirl ring 301 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com