Wafer loading and unloading system and loading and unloading method

A wafer and unloading technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of long loading and unloading time of wafers, affecting wafer production efficiency, increasing equipment manufacturing costs, etc., to reduce manufacturing costs and post-processing Effects of maintenance cost, reduction of wafer loading and unloading time, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

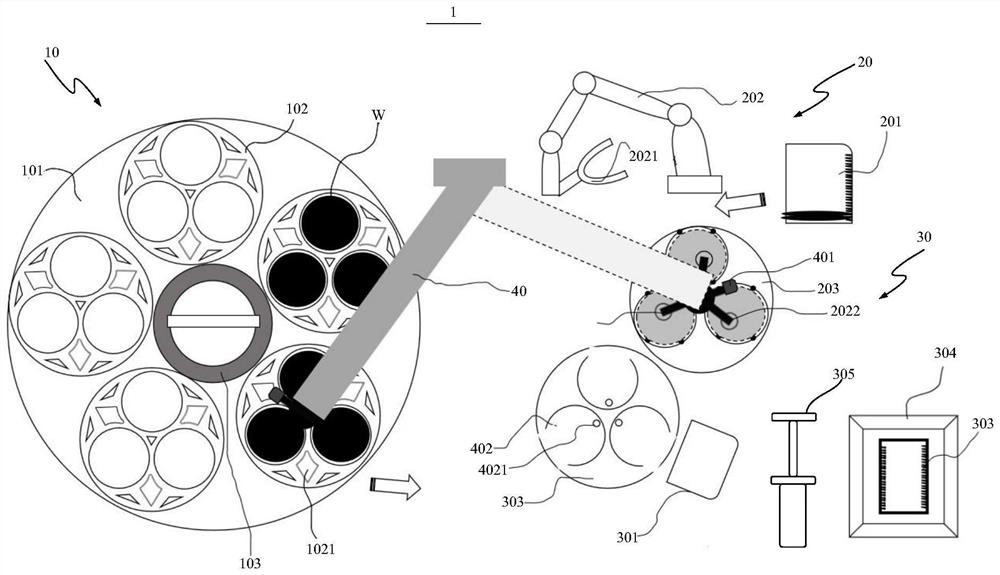

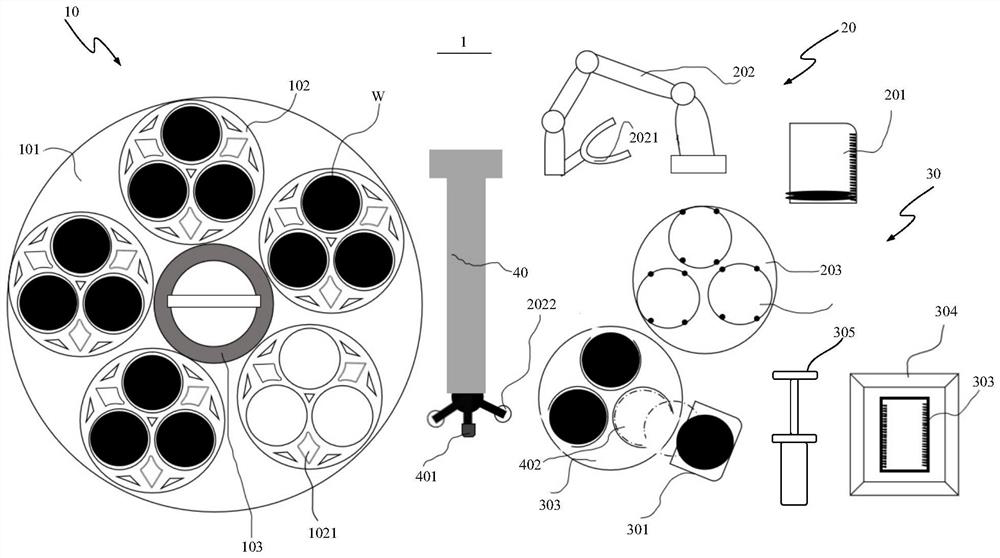

[0021] see figure 1 , which shows the wafer loading and unloading system 1A used when the wafer W is polished on both sides in the conventional technical solution, as figure 1 As shown, the wafer loading and unloading system 1A specifically includes: a carrier device 10, a loading area 20A and an unloading area 30A; wherein,

[0022] Carrier 10 includes grinding disc 101, a plurality of carriers 102 and inner pin ring 103 arranged on grinding disc 101; Used to fix the wafer W, the inner pin ring 103 is used to drive the carrier 102 to rotate, thereby polishing the wafer W through the rotation of the grinding disc 101 and the carrier 102; wherein, each carrier 102 is provided with a carrier identification hole 1021;

[0023] The loading area 20A includes a first wafer casset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com