Conductor copper bar for bus duct

A busway and conductor technology, applied in coupling devices, electrical components, connections, etc., can solve the problems that the tape cannot achieve complete insulation, manual winding inconvenience, safety hazards, etc., and achieve the effect of reducing thickness, reducing difficulty, and reducing the use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

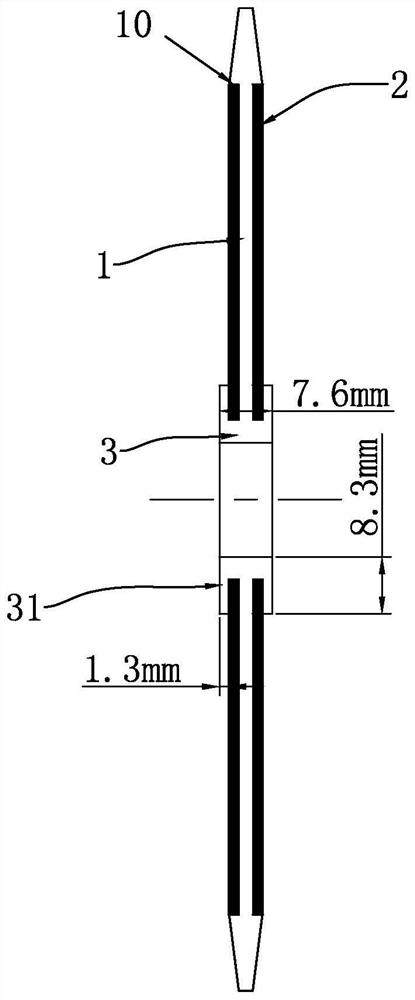

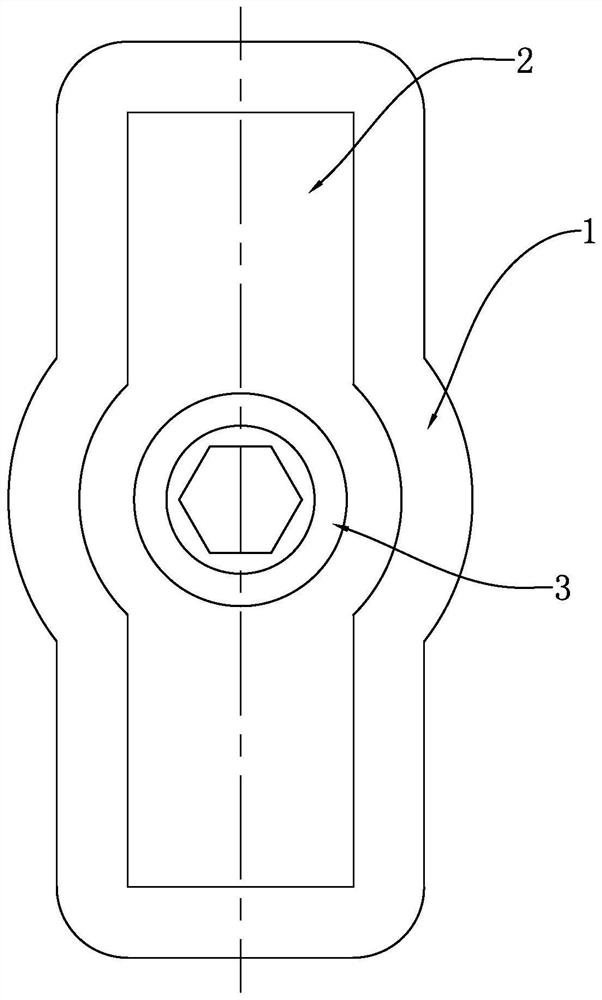

[0021] refer to Figure 1 to Figure 2 Embodiments of the present invention will be further described.

[0022] The specific structure of this embodiment: including the insulating plate 1 and the conductive sheet 2, including the insulating plate and the conductive sheet,

[0023] The insulating board 1 is formed by injection molding of an insulating material, and the insulating material is DMC, which has excellent insulating properties.

[0024] Grooves 10 with reduced thickness are formed on the upper and lower end surfaces of the insulating plate, and a connecting hole is formed in the middle through the body. The thickness of the insulating plate is 2mm, and the diameter of the connecting hole is 23mm.

[0025] The conductive sheet 2 has a through hole communicating with the connecting hole at the position corresponding to the connecting hole, and the thickness of the conductive sheet is 1.5 mm.

[0026] After the conductive sheet is pressed into the groove 10, the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com