High-temperature and high-pressure clamp holder and using method thereof

A high temperature and high pressure, gripper technology, used in instruments, scientific instruments, measuring devices, etc., can solve the problems that the gripper is difficult to reach the temperature and pressure indicators, mechanical properties are reduced, and the sealing state is damaged, so as to avoid the danger of deflagration, The effect of improving pressure resistance and reducing the need for high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

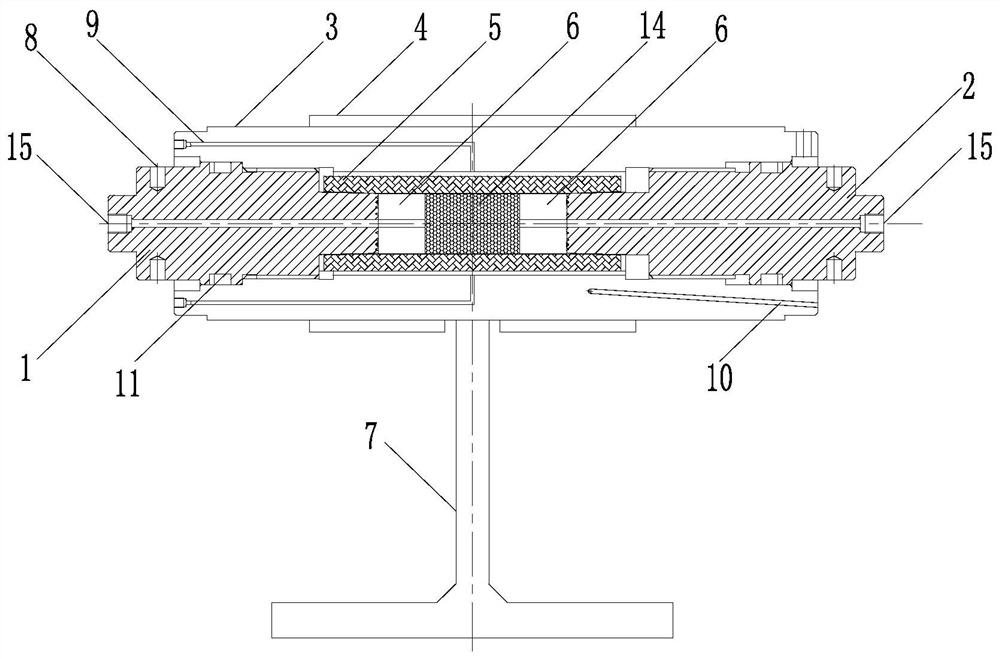

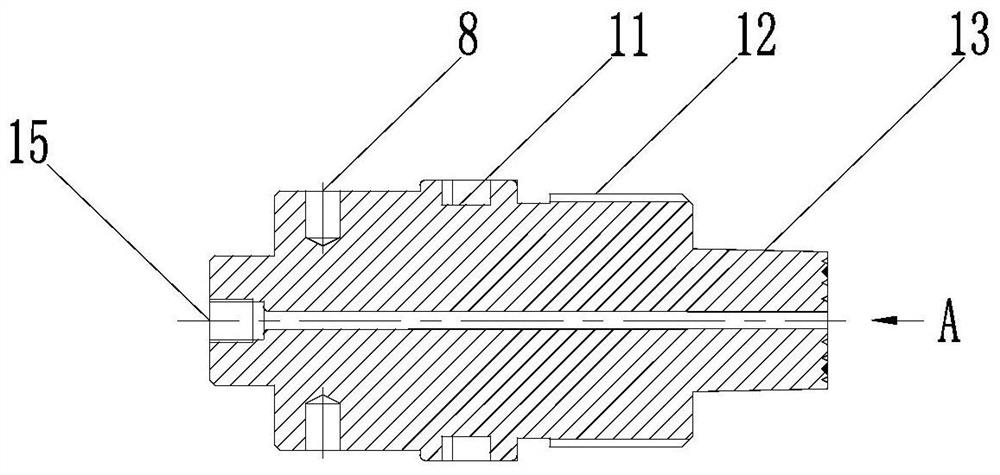

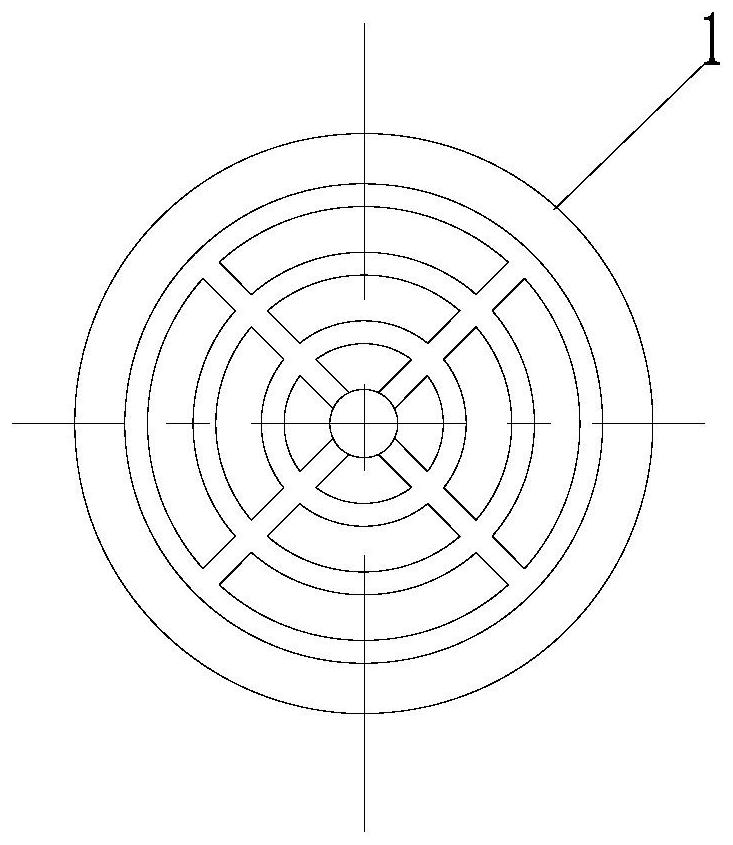

[0031] combine Figure 1 to Figure 5 As shown, the specific implementation of a high-temperature and high-pressure clamper provided by the present invention and its use method will be described.

[0032] A high-temperature and high-pressure clamper includes a first adjusting plug 1 , a second adjusting plug 2 , a cylinder body 3 , an electric heating jacket 4 , a rubber tube 5 , a spacer 6 and a bracket 7 . The first adjusting plug 1 and the second adjusting plug 2 are two identical adjusting plugs with an integrated structure, which are respectively assembled on both ends of the cylinder body 3 through threads, and the tapered plunger of the adjusting plug is inserted into the rubber tube , the sealing groove setting of the adjustment plug can meet the simulation conditions of high temperature and high pressure, and the high temperature and high pressure low permeability core seepage simulation test is carried out using this holder.

[0033] Wherein the rubber sleeve 5 is sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com