Full-automatic wire cutting and welding machine for solar panel

A solar panel, fully automatic technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as difficult maintenance, complex control system, and easy failure, so as to improve motion accuracy and positioning accuracy, The effect of reducing manufacturing costs and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

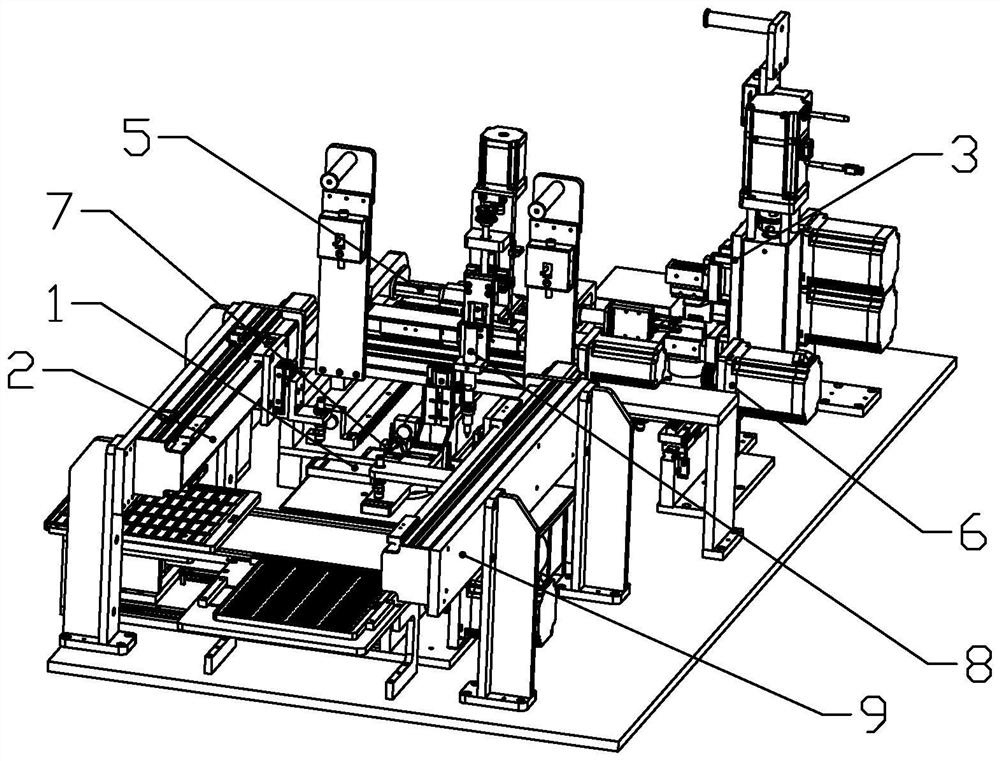

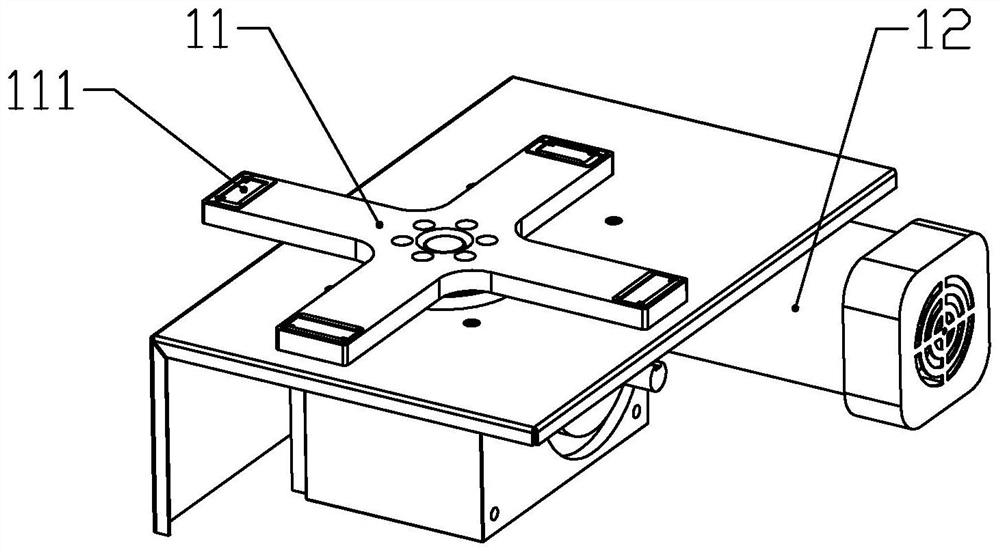

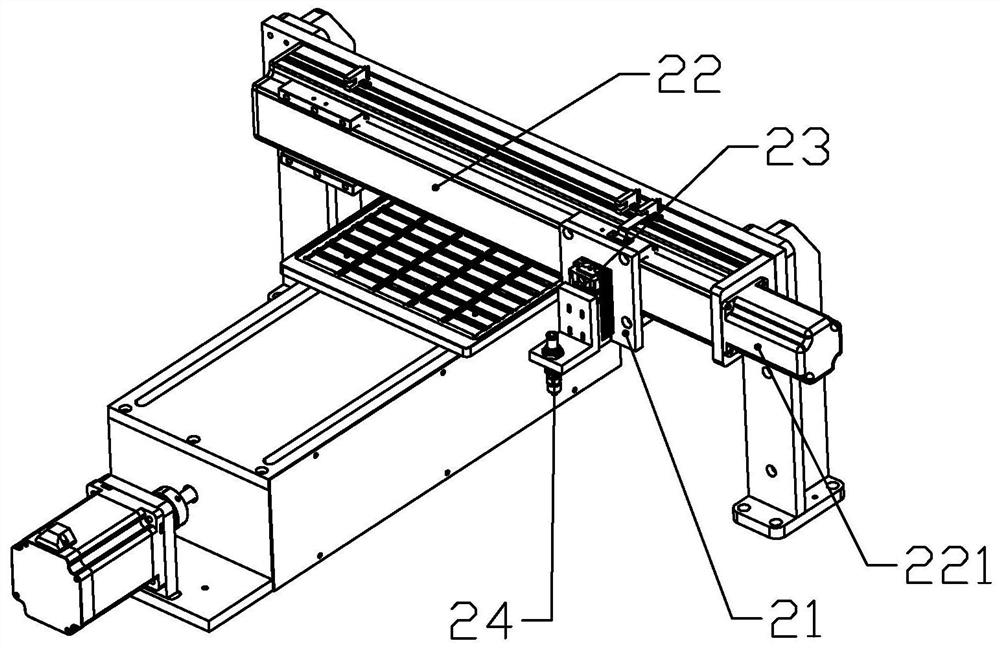

[0031] according to Figure 1 to Figure 19As shown, a solar panel automatic wire cutting and welding machine described in this embodiment includes a workbench, a positioning assembly 1 installed above the workbench for placing solar panels, and a positioning assembly 1 installed on the workbench The upper wire moving assembly 5 for moving the wires and the branch installed between the positioning assembly 1 and the wire moving assembly 5 above the workbench are used to move each wire to the solar panel welding place respectively. Wire assembly 7; the wire branching assembly includes a guide box 71 fixedly connected to the upper end opening of the upper end of the workbench, a mobile branching part 73 installed in the guide box 71 for separating the wires, two The clamping part 75 installed on the wire branching part 73 for clamping the wire and the driving part 74 installed on the lower part of the moving line branching part 73 can drive the moving line branching part 73 to mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com