Preparation method of gel type fish soup instant food

A technology for gel-type fish soup and instant food, which is applied in the directions of food ingredients, food ingredients as gelling agents, and food ingredients as taste improvers, etc. problems, to achieve the effect of enriching the taste, improving the convenience of eating, and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Preparation of prefabricated whole fish soup

[0057] S1. Raw material processing and deodorization: take snakeheaded fish, slaughter and bleed, remove viscera, wash, cut in half, and cut into pieces to obtain fish pieces; soak the fish pieces in salt solution to remove fishy smell, rinse and drain to obtain deodorized fish. Fishy fish pieces; wherein, the salt solution is obtained by mixing edible salt and water, the concentration of the salt solution is 5-15g / L, the mass ratio of the salt solution to the fish pieces is 2:1-3:1, and the soaking time is 0.5- 1.5h;

[0058] S2. Flavor optimization and nutritionalization: Fry the fishy fish pieces obtained in step S1, and fry them in an induction cooker at a temperature of 150-170°C for 1-3 minutes. Control the oil for 1 to 3 minutes to obtain prefabricated fish pieces; put the prefabricated fish pieces and water 2 to 3 times the mass into a pressure cooker and cook at 50 to 70KPa for 0.5 to 1.5 hours to obtai...

Embodiment 2

[0060] Embodiment 2: the preparation of kelp molecular sphere

[0061] S1. Raw material processing: After cooking the kelp, wash it, cut it into pieces, and soak it in 1%-3% acetic acid solution for 30-60 minutes to obtain the deodorized kelp pieces; mix the deodorized kelp pieces with purified water at a ratio of 1:3-1 The mass ratio of :5 is poured into a juice extractor to obtain kelp pulp.

[0062] S2. Flavor optimization: add salt and white pepper powder to the kelp pulp for seasoning, and stir evenly to make it tasty.

[0063] S3. Stability deployment: add sodium alginate to the kelp pulp obtained in step S2, the mass ratio of kelp pulp to sodium alginate is 100:1 to 100:2, pour it into a blender and stir until the sodium alginate dissolves, and stir The good mixture is left to stand for 0.5-2 hours, and the foam on the surface is dispersed to obtain kelp mud.

[0064] S4. Setting the shape: prepare calcium brine, which is prepared with food-grade calcium chloride, and...

Embodiment 3

[0066] Embodiment 3: the preparation of black fish gel type fish soup instant food (+kelp molecular ball+tofu cassava block)

[0067] S1. Preparation of ingredients: Tofu and cassava flour are compounded at a mass ratio of 1:1 to 2:1, kneaded evenly, rubbed and cut into pieces (0.5cm×0.5cm×0.5cm~1cm×1cm×1cm), boiled water Cooked, remove and set aside;

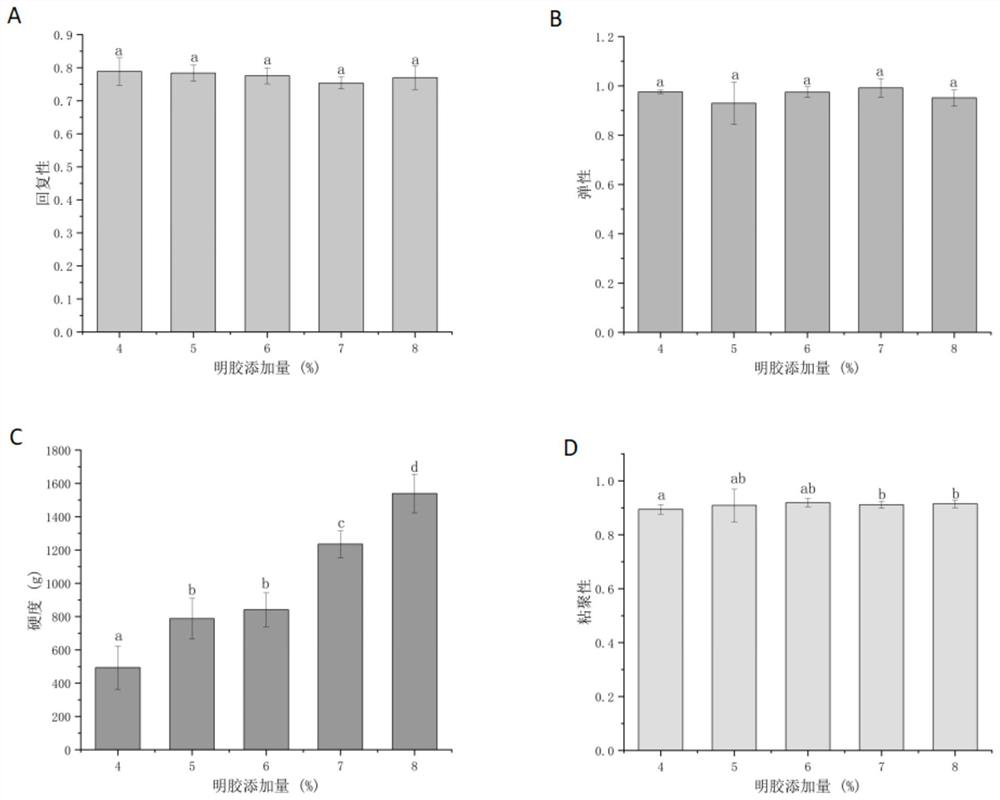

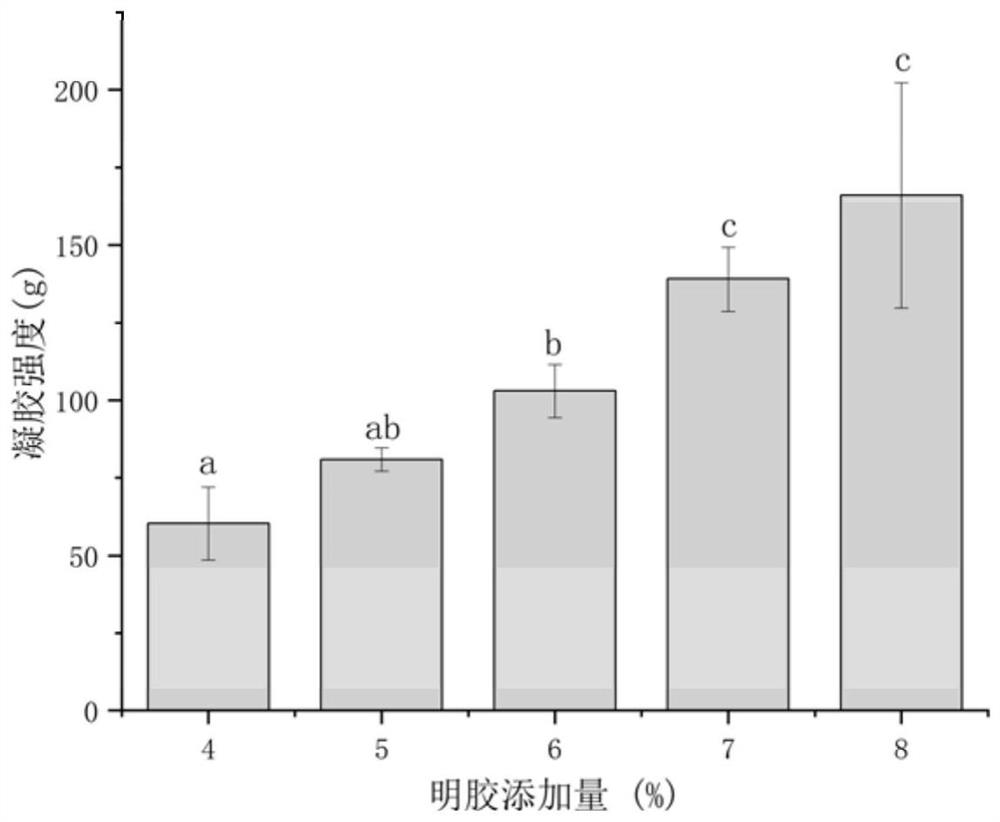

[0068] S2, jelly composite: adding mass percentage (taking prefabricated whole fish soup as a benchmark 100%) is 4%~8% gelatin, 0.05%~0.15% karaage in the prefabricated whole fish soup that embodiment 1 makes Glue, 10%-20% of the kelp molecular balls prepared in Example 2, and 5%-10% of the ingredients prepared in step S1 were placed in a water bath at 60-80°C to mix the materials evenly to obtain a mixed soup stock.

[0069] S3. Gel molding: Pour the mixed soup into the mold and let it stand, and after demoulding, pack it to obtain the black fish gel type fish soup instant food——snake fish soup jelly product. see Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com