Inductive brushless motor function detection system, method and controller

A motor controller and function detection technology, applied in the direction of single motor speed/torque control, electronic commutator, etc., can solve the problems of single board function inspection, controller production unit can not be realized, etc., to reduce production time cost, The effect of controllable production quality and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

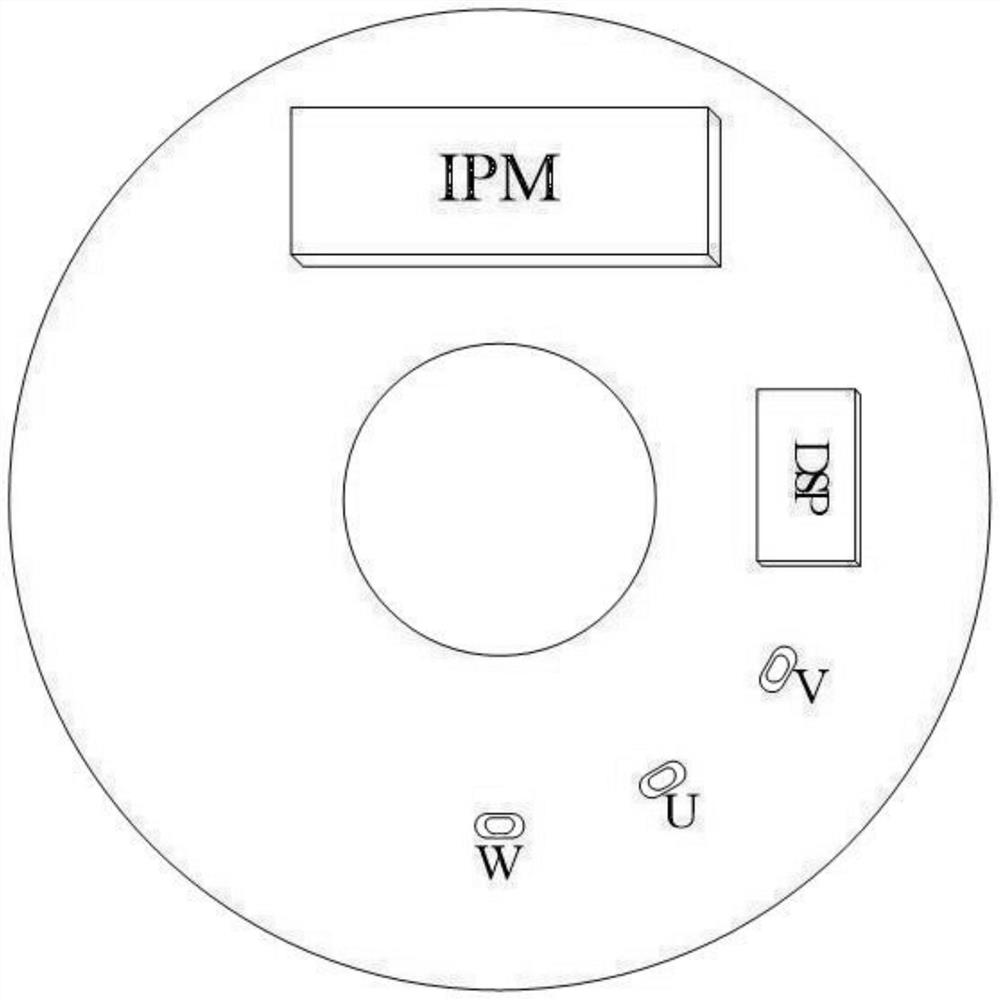

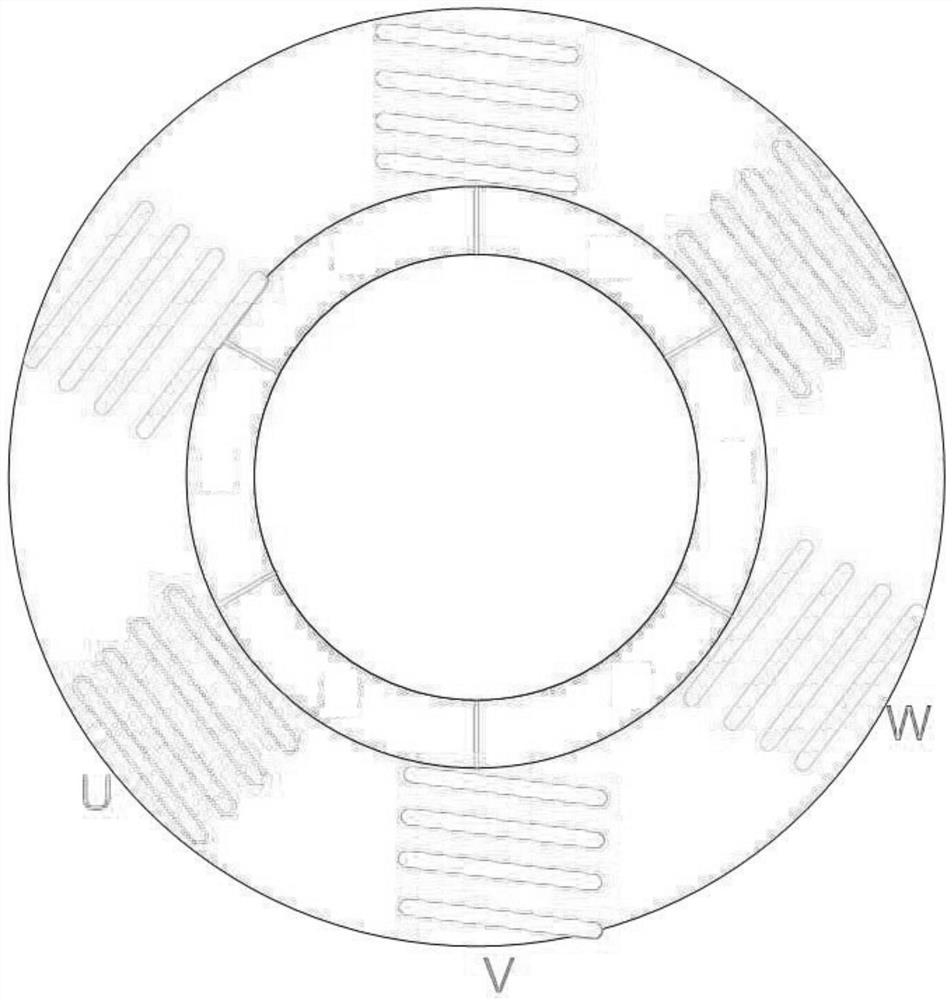

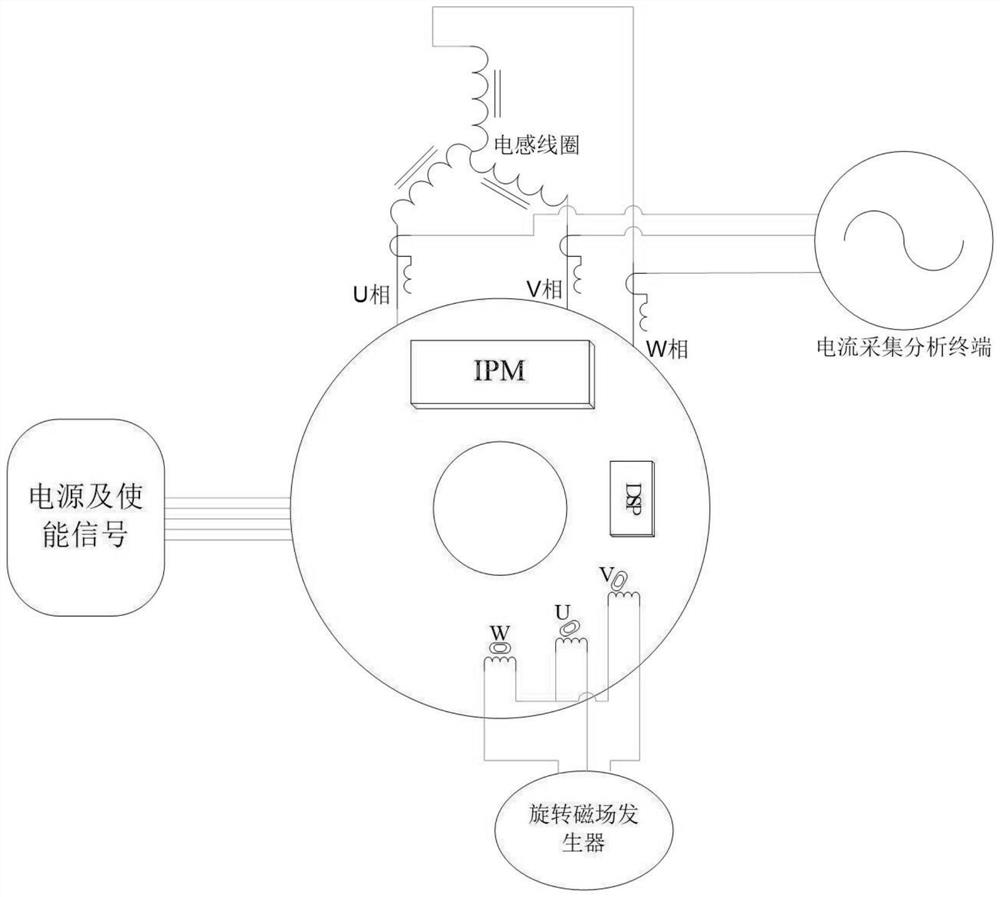

[0024] according to figure 1 , 2 , 3, the present embodiment proposes a sensory brushless motor function detection system, including a motor controller, a rotating magnetic field generator and a motor body, the control board of the motor controller is provided with a main control chip, a power The device IPM and the position sensor elements U, V, W; the motor body is provided with a stator coil, and the stator coil is a three-phase coil U, V, W;

[0025] The motor controller is connected with three-phase coils U, V, W, and the position sensor elements U, V, W are all provided with inductance coils.

[0026] The motor controller is connected with three-phase coils U, V, W.

[0027] The inductance coil is driven by a rotating magnetic field generator, and the rotating magnetic field generator is realized by a non-inductive FOC motor driving board or a square wave motor driving board or a stepping motor square wave driving board.

[0028] The motor controller is driven by a po...

Embodiment 2

[0031] according to figure 1 , 2 , 3, this embodiment proposes a sensory brushless motor function detection method, applied to the motor controller, including the following steps:

[0032] Use the rotating magnetic field generator to drive the inductance coils under the position sensor elements U, V, and W to generate three fixed magnetic fields with different strengths; the position sensor elements U, V, and W sense the static position information of the inductance coil magnetic field to provide motor control The main control chip obtains the enabling signal and the static position information of the magnetic field (inductance simulation), and then outputs the SVPWM wave to the power device IPM through algorithm operation, driving the three-phase coil U, V, W; using the rotating magnetic field generator Continuously change the current of the inductor coil to realize the change of the magnetic field strength, and simulate the change of the magnetic field strength when the rot...

Embodiment 3

[0035] This embodiment proposes a sensory brushless motor function detection controller, including a computer-readable storage medium storing a computer program and a processor, and when the computer program is read and run by the processor, the described A method for detecting the function of a sensory brushless motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com