Novel power line adapter connector

A technology for transfer connectors and power cords, applied in the direction of connection, two-part connection devices, circuits, etc., can solve the problems of increasing operations, increasing the number of sleeve disassembly, and affecting the service life of products, so as to reduce operations and improve wiring Efficiency, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

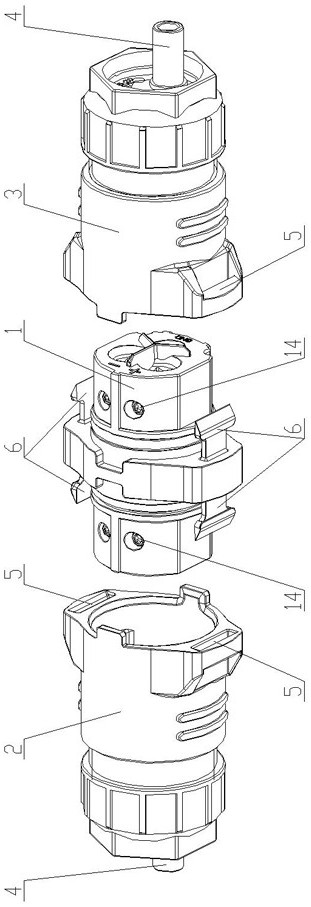

[0031] Embodiment one: see figure 1 , the base sleeve 2 and the movable sleeve 3 of this embodiment have adopted exactly the same structure, the outer sides of the movable sleeve 3 and the base sleeve 2 are provided with claw grooves 5, and the wiring insulator 1 is provided with two sockets for respectively inserting them. There are multiple claws 6 in the side claw groove 5, and the inner side of the wiring insulator 1 is provided with a contact piece 13. The two ends of the wire 4 extend from the outside of the two sleeves respectively, and then extend into the contact piece 13 and pass through the wiring insulator. 1, screw the crimping screw 14 that establishes and compress, realize the energization connection of both sides lead wire 4.

[0032] The two sleeves and the wiring insulator 1 are connected in the form of the claw 6 and the claw groove 5. After the wire 4 is connected, the sleeve and the wiring insulator 1 can be directly inserted in pairs to realize the instal...

Embodiment 2

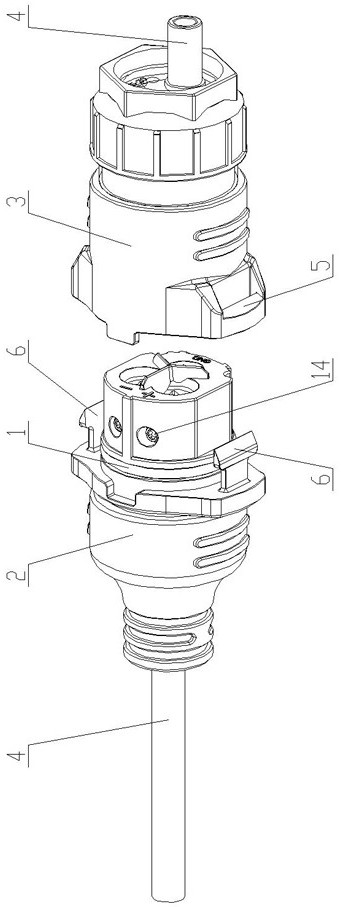

[0033] Embodiment two: see Figure 2-8 , the outer side of the movable sleeve 3 of this embodiment is provided with claw grooves 5, and the wiring insulator 1 is provided with claws 6, and the basic sleeve 2 is plastic-sealed and fixed to the wires 4 extending into its interior, and the basic sleeve 2 is fixed on the wiring On the insulator 1, so that the basic sleeve 2 can be plastic-sealed in advance during the production process, and it is integrated with the wiring insulator 1 during production. When it is used on site, it is only necessary to wire one side of the movable sleeve 3. The basic sleeve 2 is no longer disassembled, which simplifies the on-site wiring process, further reduces the redundant operation of disassembling the sleeve, and reduces the wear and tear on the product caused by multiple disassembly.

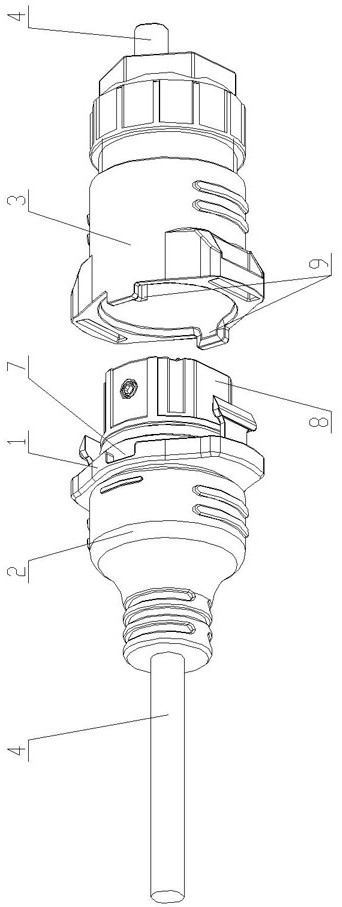

[0034] The outer side of the wiring insulator 1 is provided with an anti-rotation groove 7 and an anti-rotation flat 8, and the inner side of the movable sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com