Wire moving and overturning mechanism of solar panel wire welding machine

A solar panel and flip mechanism technology, applied in welding equipment, semiconductor devices, auxiliary devices, etc., can solve the problems of inability to meet actual use requirements, complex control systems, unfavorable production and use, etc., to shorten the movement time, improve the operation accuracy, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

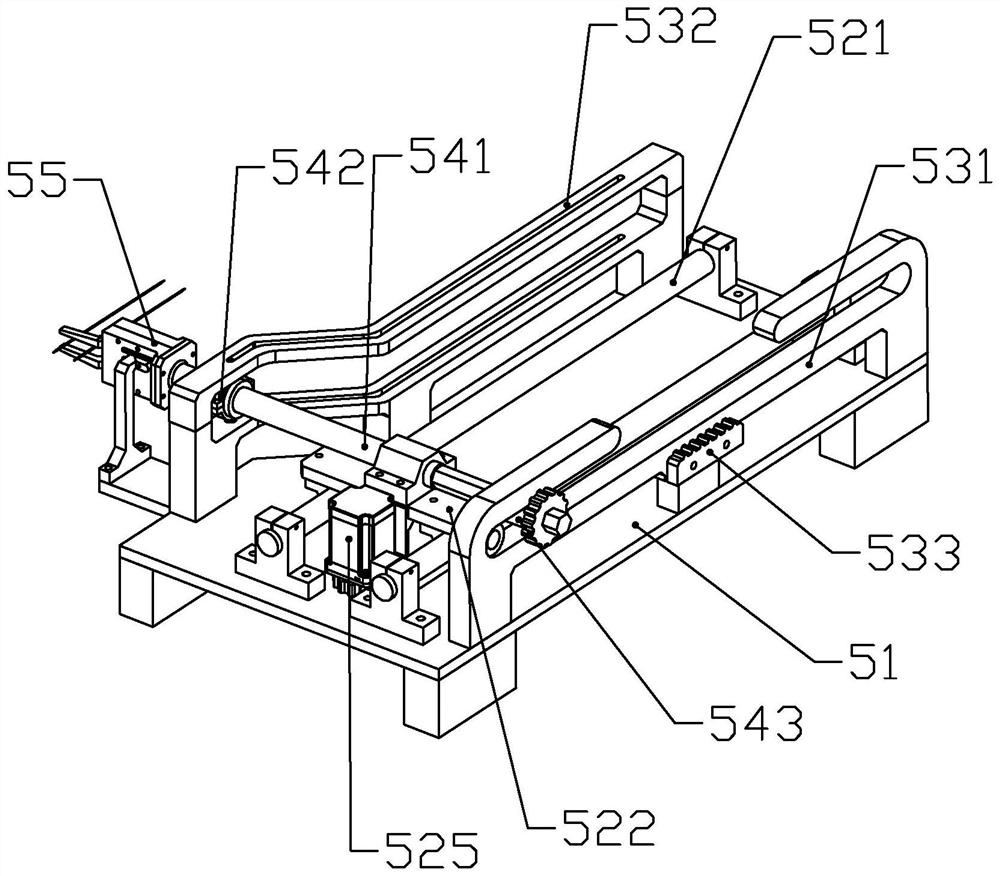

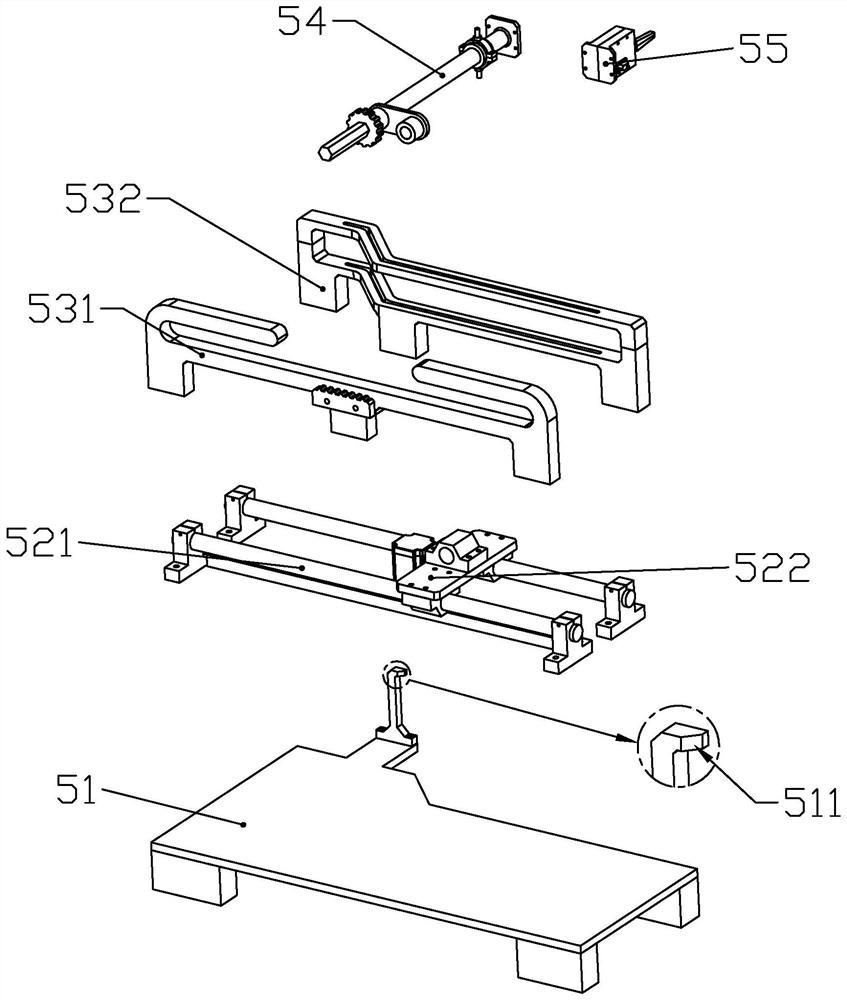

[0042] according to Figure 1 to Figure 8 As shown, the wire moving and turning mechanism of a solar panel wire bonding machine described in this embodiment includes a mounting base 51, a sliding plate 522 slidably connected to the mounting base 51, and a sliding plate 522 fixedly connected to the sliding plate 522. The wire-moving motor 525 for driving the slide plate 522 to slide; the slide plate 522 is rotatably connected with an overturning portion 54; the direction of the rotation axis of the overturning portion 54 is perpendicular to the sliding direction of the slide plate 522; One end of the turning part 54 is fixedly connected with a clamping part 55 for clamping the wire; the turning part 54 includes a turning bar 541 rotatably connected to the sliding plate 522, which is slidably connected along the axial direction of the turning bar 451. The flip sliding tube 543 on the outer periphery of the flip rod 541 for driving the flip rod 541 to rotate in the circumferentia...

Embodiment 2

[0076] according to Figure 1 to Figure 17 As shown, a solar panel automatic cutting and welding machine described in this embodiment includes a workbench, a positioning assembly 1 installed on the workbench for placing solar panels, and a positioning assembly 1 installed on the workbench The feeding assembly 2 used to place the solar panel to the positioning assembly 1, the tangent assembly 3 installed on the workbench for wire cutting and tinning, the tangent assembly 3 installed on the workbench for holding liquid tin Tin dipping assembly 4, a wire moving assembly 5 installed on the workbench for moving and flipping wires, a pull wire assembly 6 installed on the workbench for straightening wires, and a wire assembly installed on the workbench The wire branch assembly 7 for moving the separated wires, the welding assembly 8 installed on the workbench for welding the wires to the solar panel, and the solar panel installed on the workbench for moving the welded wires Take the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com