Semiconductor factory control separation blade management method

A management method and semiconductor technology, which is applied in the field of control sheet management in semiconductor factories, can solve problems such as damaged and scrapped block control sheets, increased loss of block control sheets, etc., to maintain accuracy, maintain timeliness, and reduce usage cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

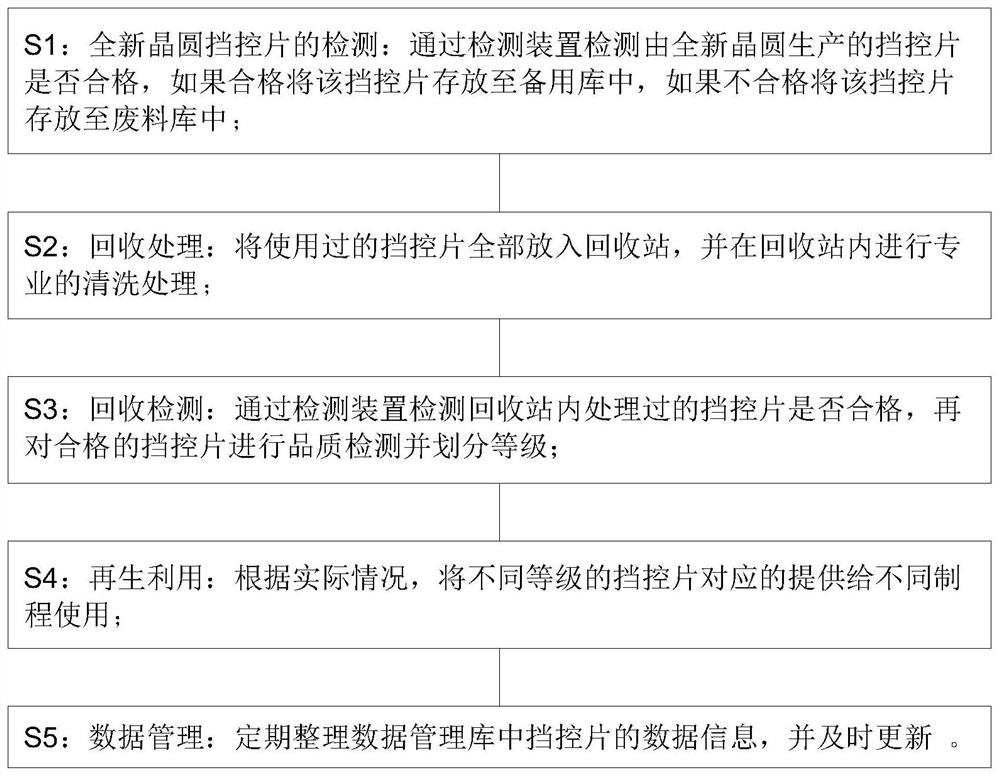

[0022] Such as figure 1 As shown, in the semiconductor factory control block management method described in the present invention, the steps of the management method of the control block are as follows: S1: Detection of the new wafer block control sheet: detect the new wafer produced by the new wafer through the detection device Whether the control sheet is qualified, if it is qualified, store the control sheet in the spare warehouse, if it is unqualified, store the control sheet in the waste warehouse; S2: Recycling: Put all the used control sheets into the recycling bin , and carry out professional cleaning treatment in the recycling station; S3: Recycling inspection: use the detection device to detect whether the processed control sheets in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com