Wind driven generator coating fatigue life optimization design method considering raindrop erosion

A wind turbine, fatigue life technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as waste of wind turbine production capacity, and achieve the effect of reducing the search space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments, and the purpose and effect of the present invention will become clearer. It should be understood that the specific embodiments described here are only used to explain the present invention and are not intended to limit the present invention.

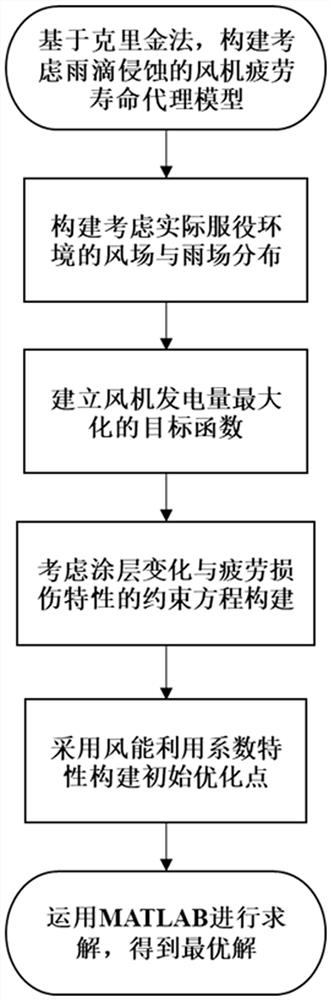

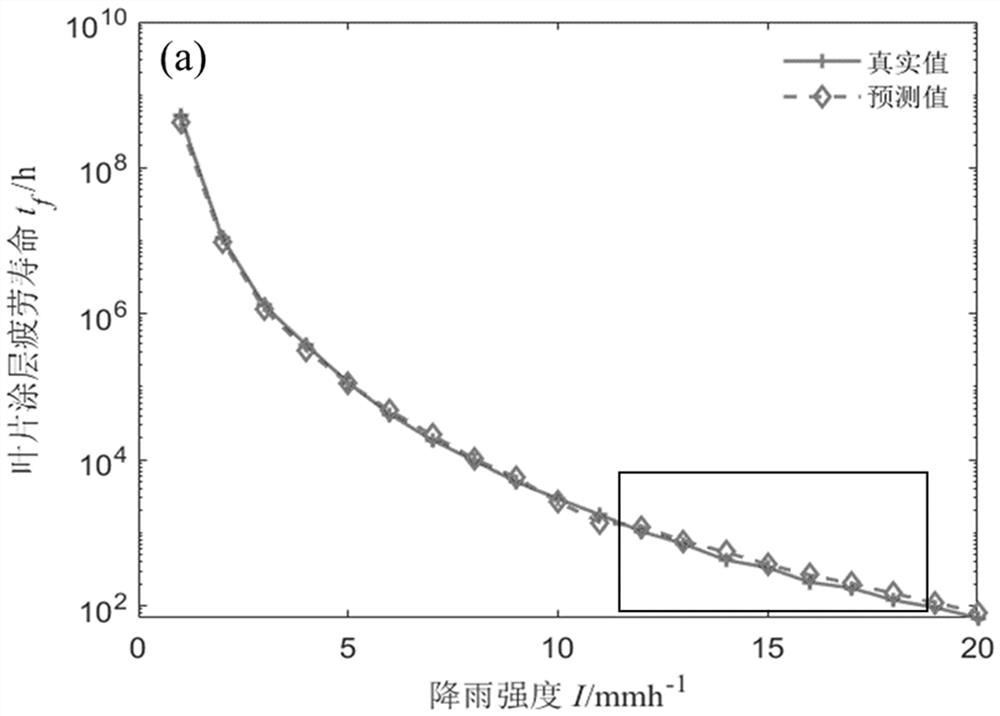

[0076] The wind turbine blade coating fatigue analysis method considering raindrop erosion of the present invention uses the Kriging method to realize the construction of a wind turbine blade coating fatigue life proxy model; considers the construction of the probability distribution of wind field and rain field in the actual service environment ; take the maximum power generation of the wind turbine as the objective function to design the speed of the wind turbine; construct the constraint equation according to the change characteristics of the fatigue life of the blade coating in different rainfall intensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com